5. OPERATION

5.1. Preparation the vise to operation

After unpacking the vise please:

➢

Check if none of parts is missing,

➢

Remove the preservative from vise surfaces,

➢

The mating surfaces of clamping inserts (4), fixed jaw (2) and movable jaw (3)

should be covered with some grease,

➢

While transporting the vise to machine tool make sure that the holder is

protected against self-tilting by means of the screw (10),

➢

Screw (10) should not be screwed to the vise guides,

➢

Before attempting the operation check the gap width between clamping

inserts and jaws as stated in point 5.5.

5.2. Vise positioning on machine tool

Use the parallel and longitudinal keyways and fixture keys (13) to position the

vise on the machine-tool table.

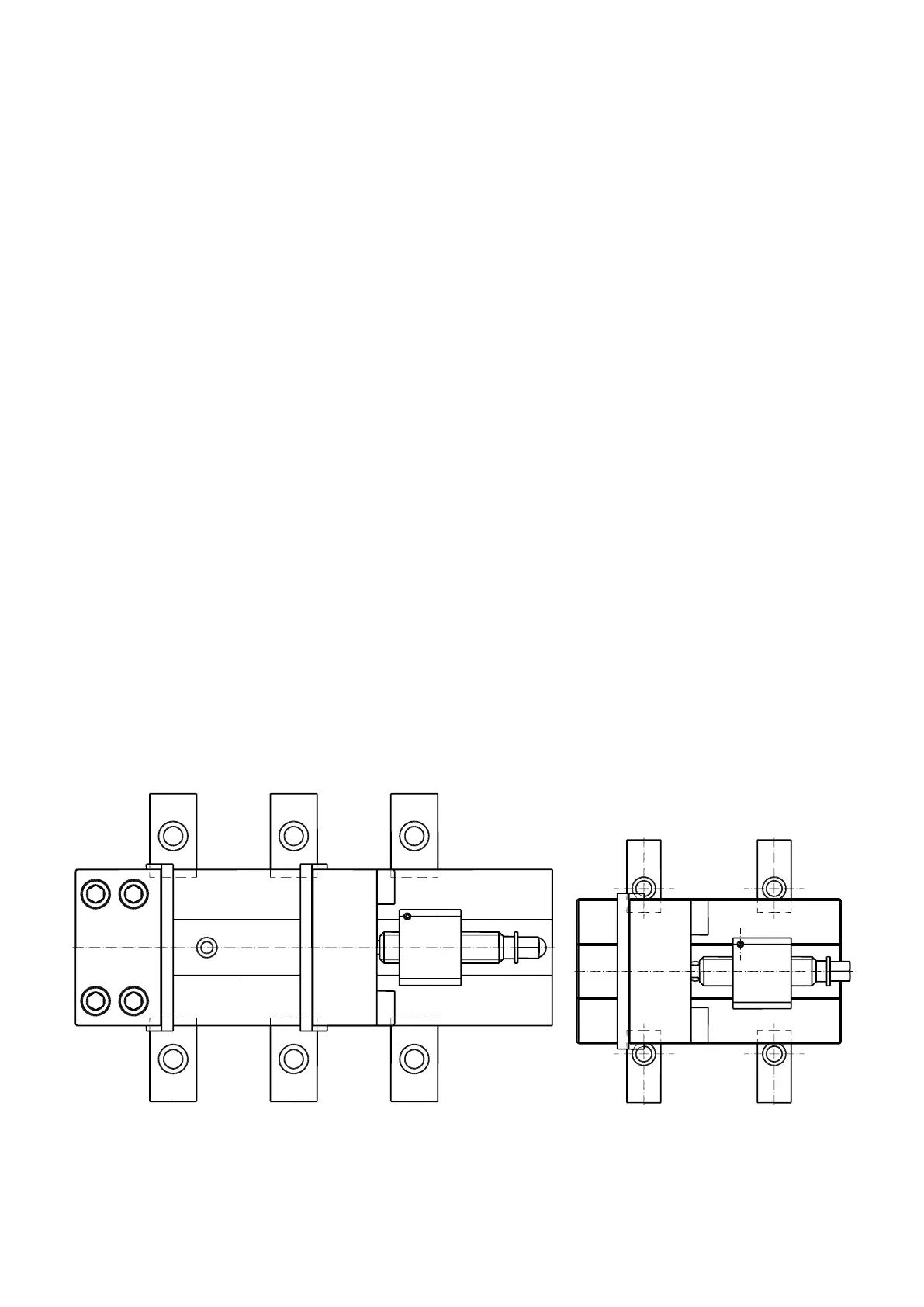

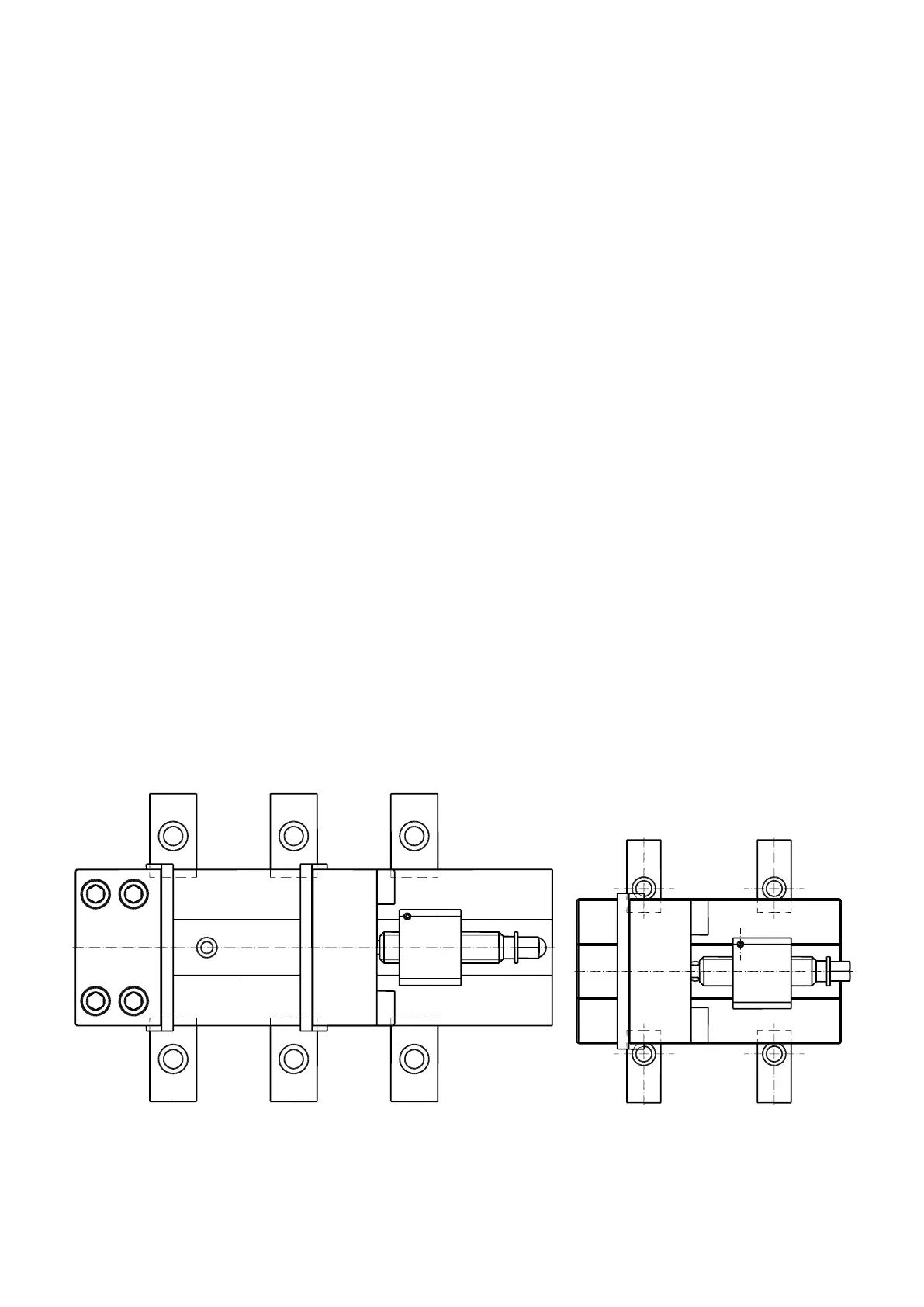

5.3. Fastening vises on the machine-tool table

Machine vises of 6620 type may be fastened on machine-tool table in

longitudinal and transverse way. The transverse fastening with clamping lugs,

delivered with vises, is able on tables with dimensions as shown in Fig.7 and Table

4. Location of clamping lugs is shown in Fig. 6.

Fig. 6. The way of fastening machine vises of 6620 type on machine-tool table.

Loading...

Loading...