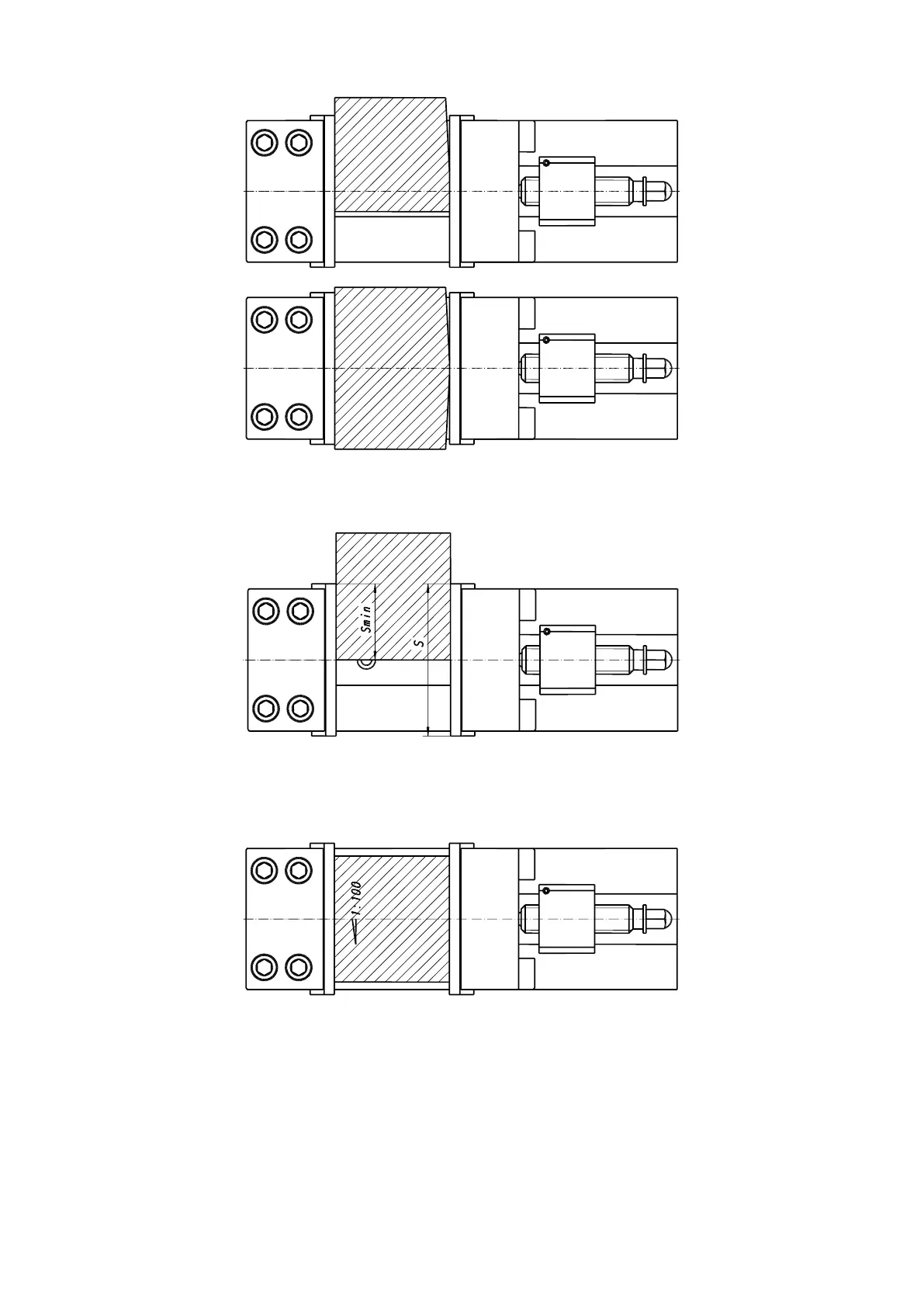

The ways of clamping the workpieces of irregular shapes are shown at Fig. 12,

13 and 14.

Fig.12. The way of clamping the workpiece of irregular shape.

The right effectiveness of clamping is achieved when S

min

>1/2 S.

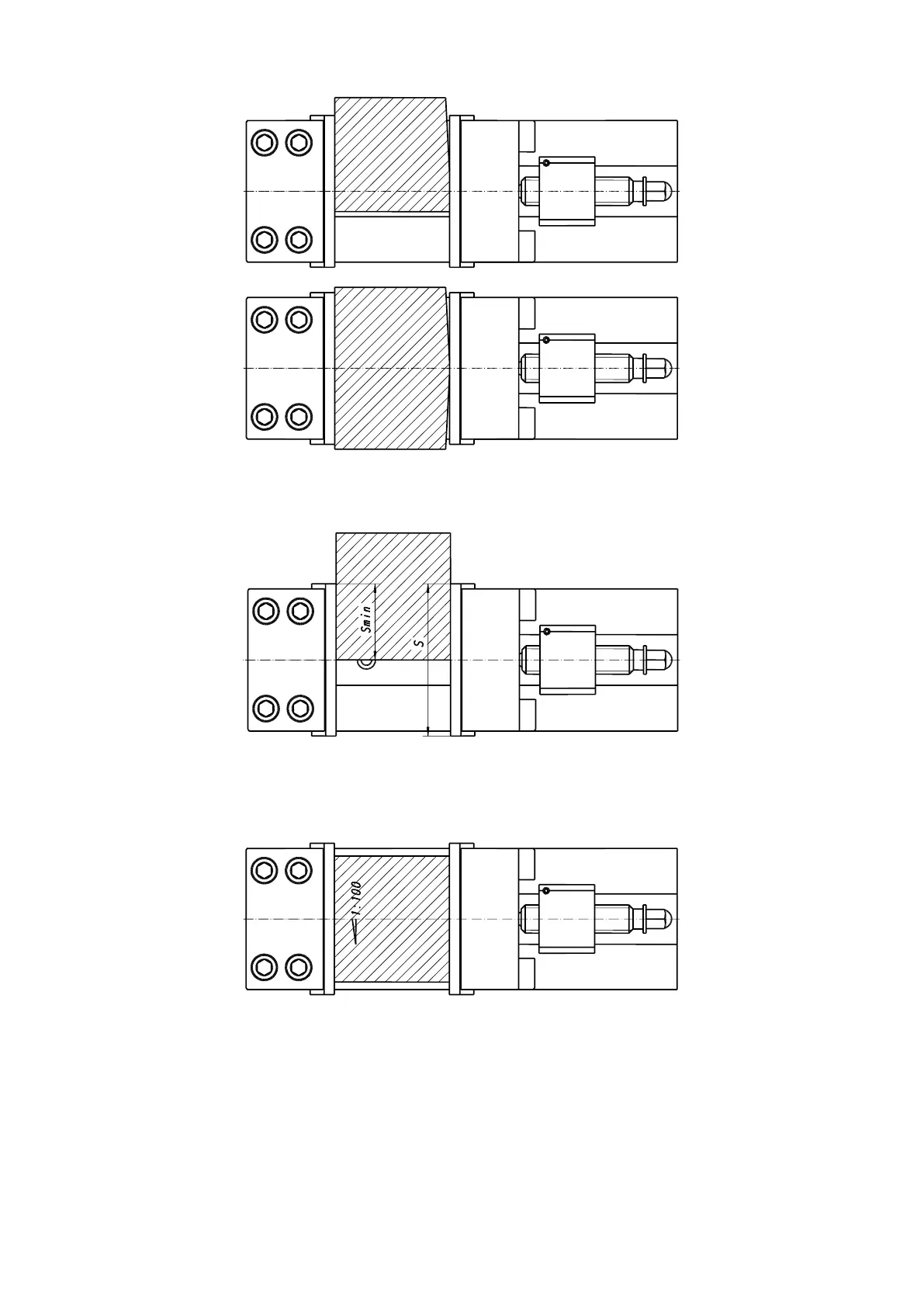

Fig. 13. The way of clamping the workpiece of irregular shape.

The clamping the workpiece with taper lower then 1:100 may be effective only

when it is clamped at entire length of jaws.

Fig. 14. The way of clamping the workpiece of irregular shape.

Jaw insert should be mounted on jaw guides when:

➢

Clamping the workpiece with jaw edges

➢

Clamping the workpiece with grooved surface of stationary jaw

➢

Clamping the workpiece with the prismatic or stepped jaw inserts

(Fig. 22, Fig. 23)

➢

Clamping the workpiece with the grooved jaw inserts (Fig. 21),

Loading...

Loading...