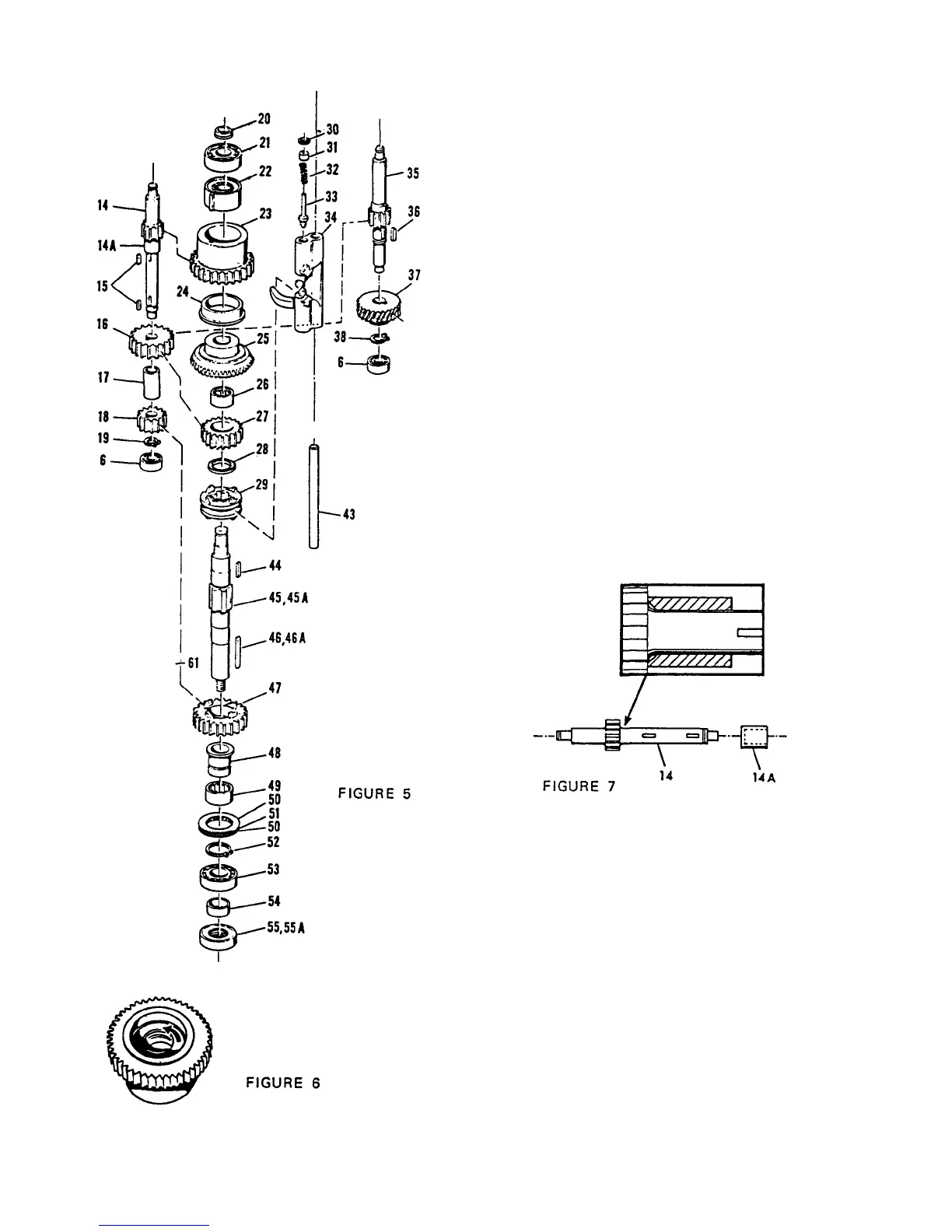

4. DISASSEMBLY OF SUN SHAFT ASSEMBLY. REFER

EXP. VIEW FIGURE 5.

A. REMOVE SPUR GEAR & SLEEVE (23), CLUTCH

(22), BEARING (21) AND SPACER (20) FROM

SHAFT AS AN ASSEMBLY.

B. IN AN ARBOR PRESS, PRESS CLUTCH (22) AND

BEARING (21) FROM GEAR (23). PRESS BEVEL

GEAR (25) OFF SHAFT. ITEMS 26, 27, 28 & 29

WILL SLIDE OFF SHAFT.

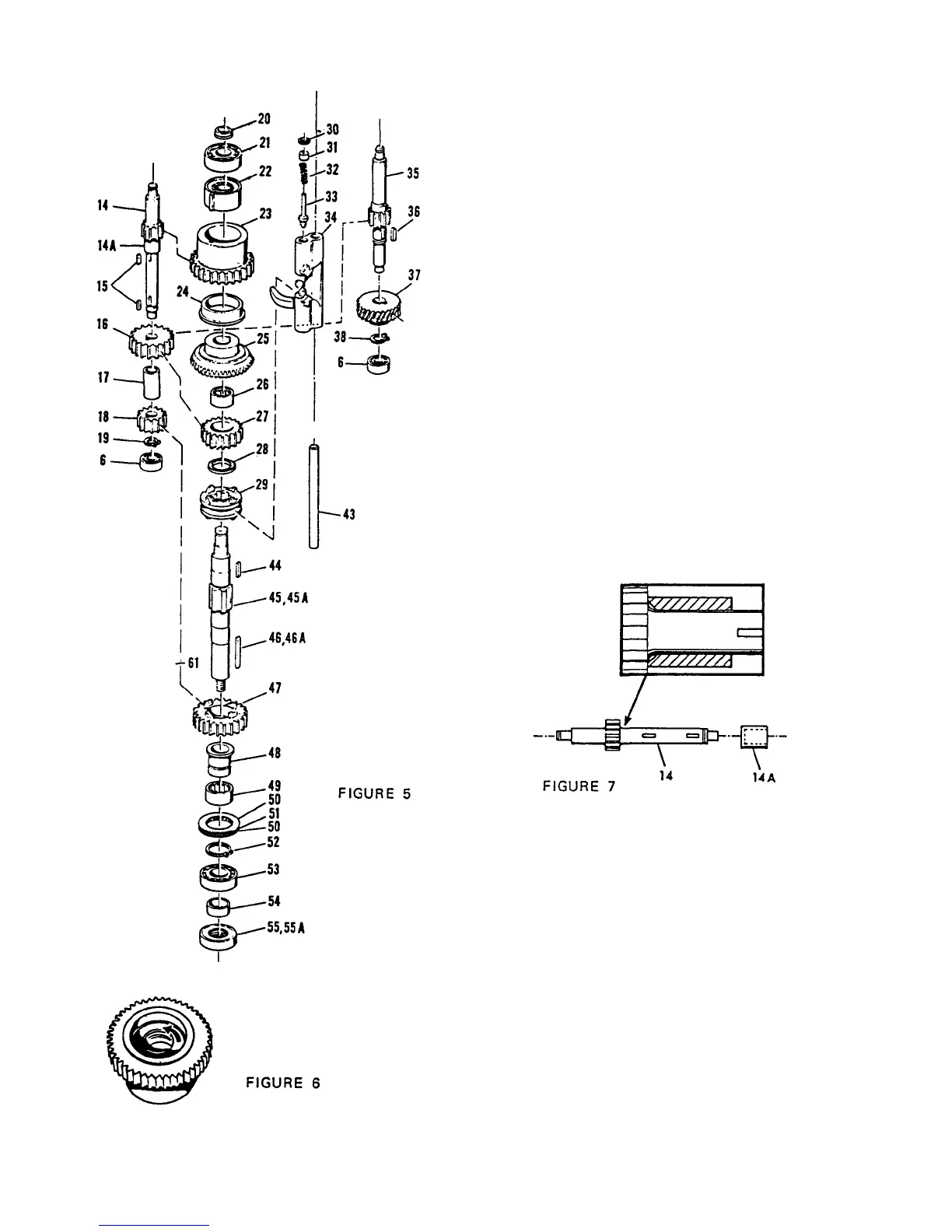

NOTE: WHEN REASSEMBLING NEW CLUTCH (22)

INTO GEAR (23) ARROW MARKED ON CLUTCH

MUST BE VISIBLE AS SHOWN IN FIGURE 6.

C. PRESS BEARING (53) OFF SHAFT. REMOVE

SNAP RING (52). ITEMS 47 THRU 51 WILL SLIDE

OFF SHAFT.

5. DISASSEMBLY OF INTERMEDIATE SHAFT. REFER

TO FIGURE 5.

A. PRESS BEARING (6) OFF SHAFT (14). REMOVE

SNAP RING (19) AND PRESS OFF GEAR (18). SLIDE

OFF SLEEVE (17) AND PRESS OFF GEAR (16).

NOTE: IN EARLY MODEL TRANSMISSIONS SHAFT

(14) HAD A MACHINED SHOULDER. BEGINNING IN

1971 HEAVY DUTY SHAFTS WERE USED WITH A

SPACER (14A) INSTEAD OF THE MACHINED

SHOULDER. WHEN REASSEMBLING SPACER (14A)

THE CHAMFERED END MUST FACE FIXED GEAR ON

SHAFT (SEE FIGURE 7).

6. DISASSEMBLY OF PIN ION SHAFT. REFER TO

FIGURE 5.

A. PRESS BEARING (6) OFF SHAFT (35). REMOVE

SNAP RING (38) AND PRESS OFF WORM GEAR (37).

REASSEMBLY & INSTALLATION

(1) REASSEMBLY SUBASSEMBLIES IN REVERSE

ORDER OF DISASSEMBLY AND INSTALL IN

REVERSE ORDER OF REMOVAL.

(2) REFILL TRANSMISSION WITH #50 HEAVY DUTY

OIL. (HYDROL MASTER 500 OR EQUIVALENT)

3 PINTS - M-5-3330 TRANS.

4 PINTS - M-5-1505 TRANS.

18

Loading...

Loading...