13

4.8 The abrasive valve

Between the abrasive storage hopper and the feed spout there is a valve incorporating a permanent magnet in

order to control the abrasive flow towards the blastwheel. Any change in the opening of the magnetic valve

causes the amount of abrasive fed to the blastwheel to change. The change in the abrasive fed can be read

from the ammeter. The valve is hand-operated by the abrasive control cable. This control cable is located on

the control box and can be adjusted so that any quantity of abrasive can be fed to the blastwheel. Optimum

blast cleaning power is reached when the ammeter indicates the operating current. It is not permitted to blast

with a higher current value.

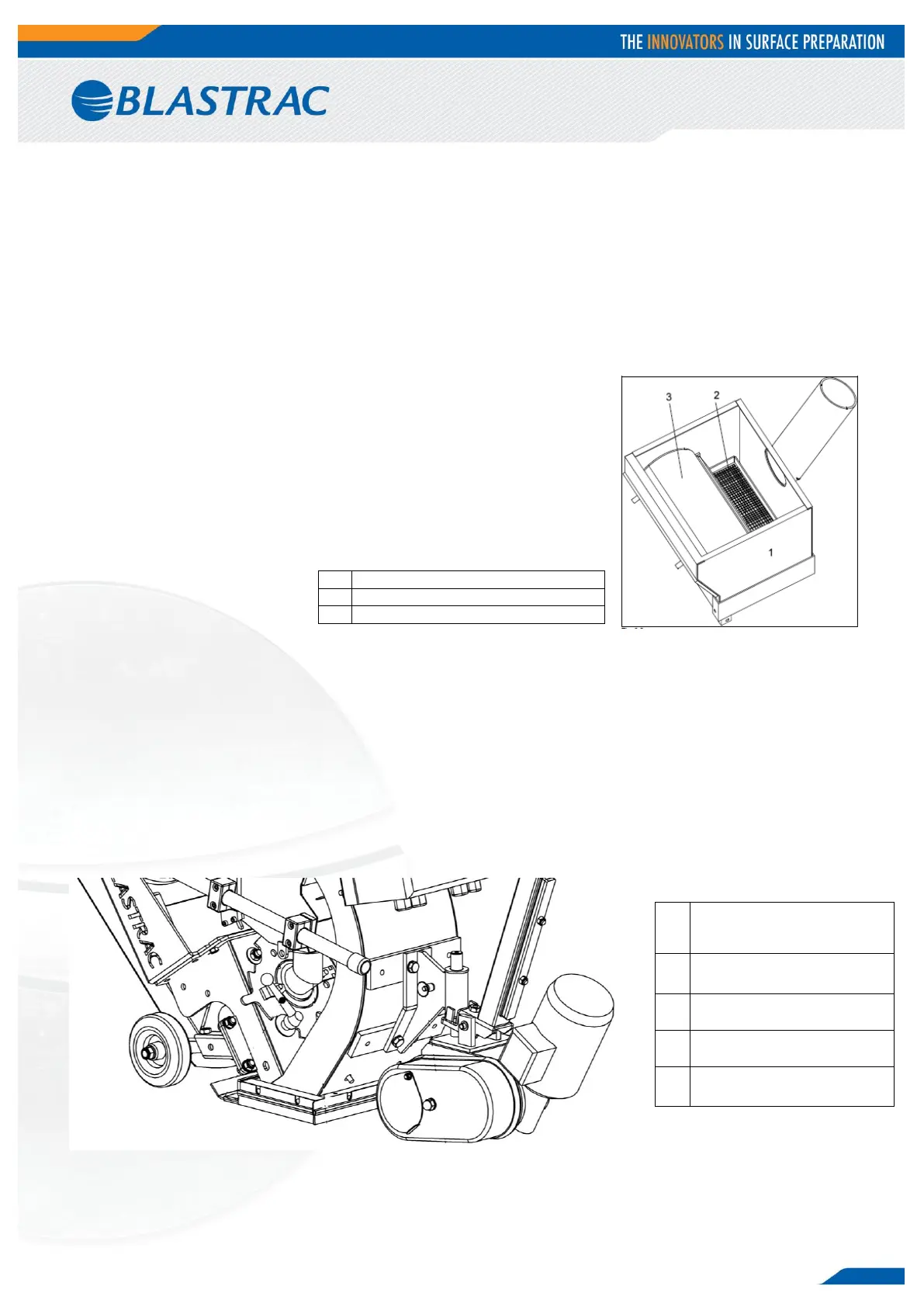

4.9 Separator

The abrasive separator is mounted to the end of the rebound plenum. It

separates the abrasive from contaminants and feeds the cleaned abrasive

back to the abrasive circuit. A wire mesh is fitted to prevent any large

contaminants from getting into the blast wheel. In order to clean the wire

mesh drawer, the separator cover can be removed or the wire mesh drawer

can be removed from the side.

During operation U should check the separator tray every 3 hours for

foreign matter and large contaminants.

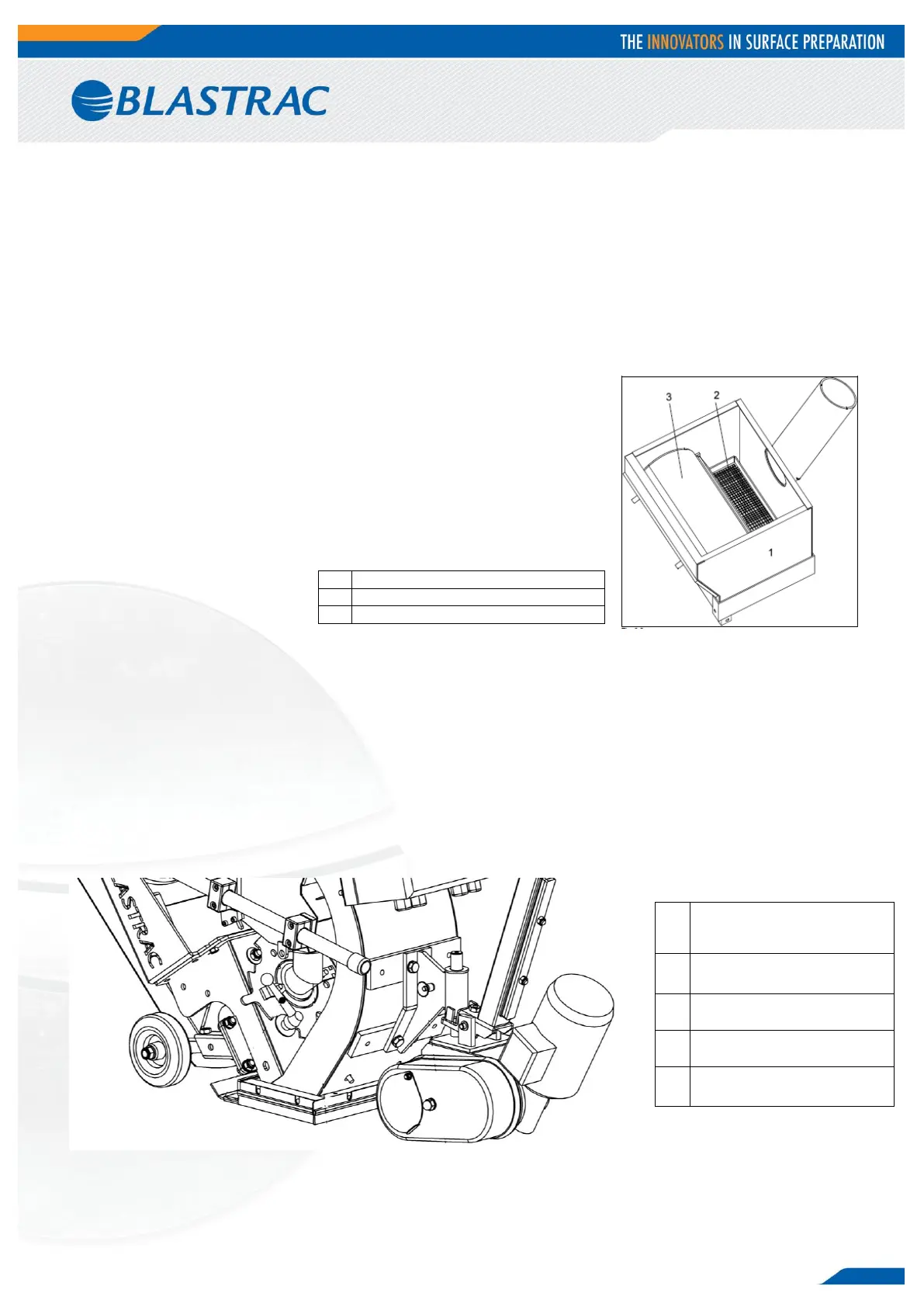

4.10 Abrasive sealing

Magnetic seals are fitted to the front and the sides of the blast housing outlet and are surrounded by brush

seals. At the rear there are two seals sliding over the floor. The seals are employed to seal the blasting area in

a way to avoid leakage of any abrasive.

The correct height adjustment of the magnetic seals (8–10 mm) is very important for optimum functionability

of the machine.

The adjustment is done using the 3 setting screws (one each at the rear wheels and one at the front drive wheel

bracket below the control box).

The height of the brush seals should be maximum 1 mm above the surface. Adjustment is effected through slotted

holes.

Separator drawer (wire mesh)

Setting screw rear wheel

(quantity: 2)

One on each rear wheel.

Setting screw drive wheel

(quantity: 1)

Loading...

Loading...