BL6-U Parallel Integrated Controller Quick Commissioning User Manual

12

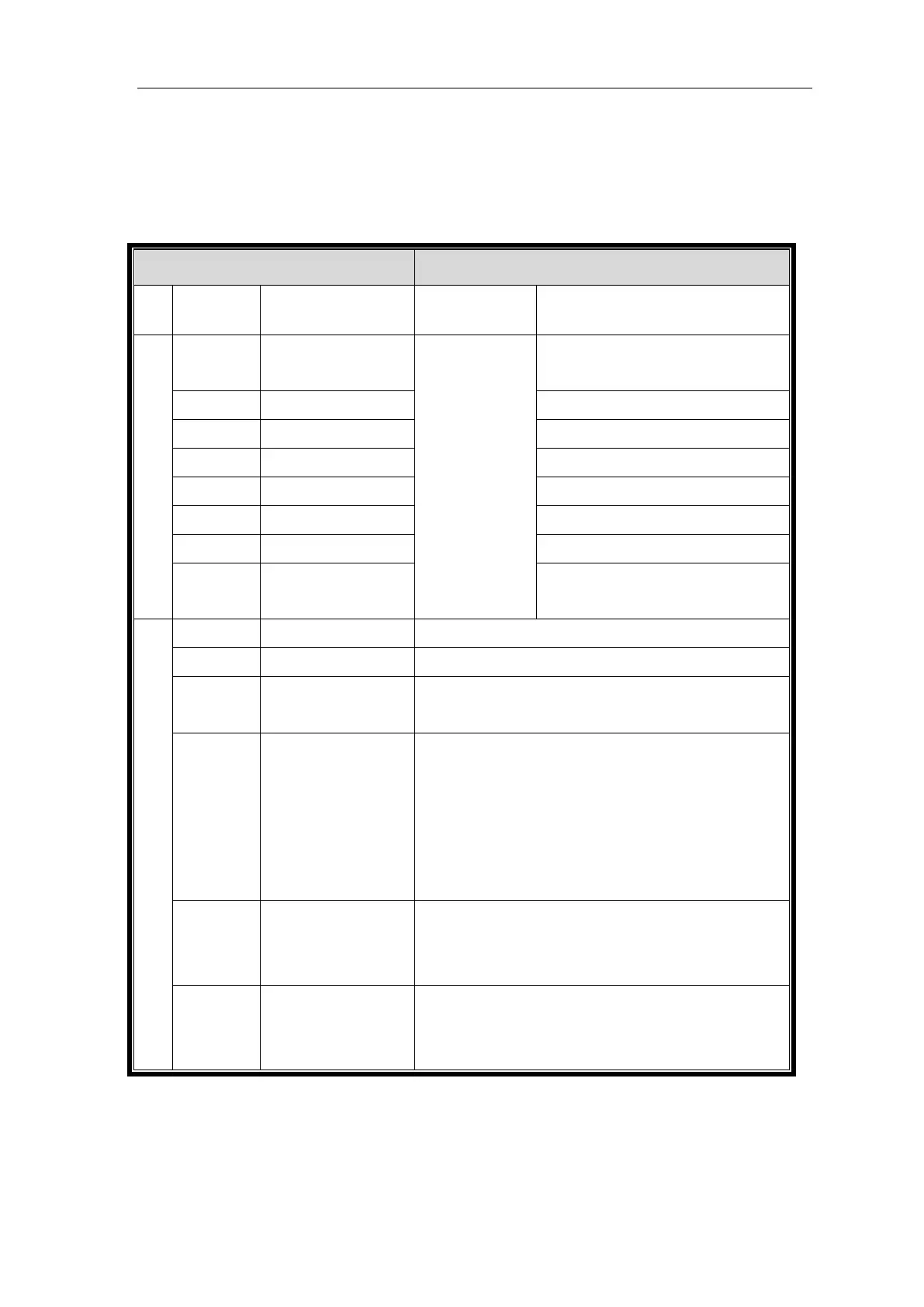

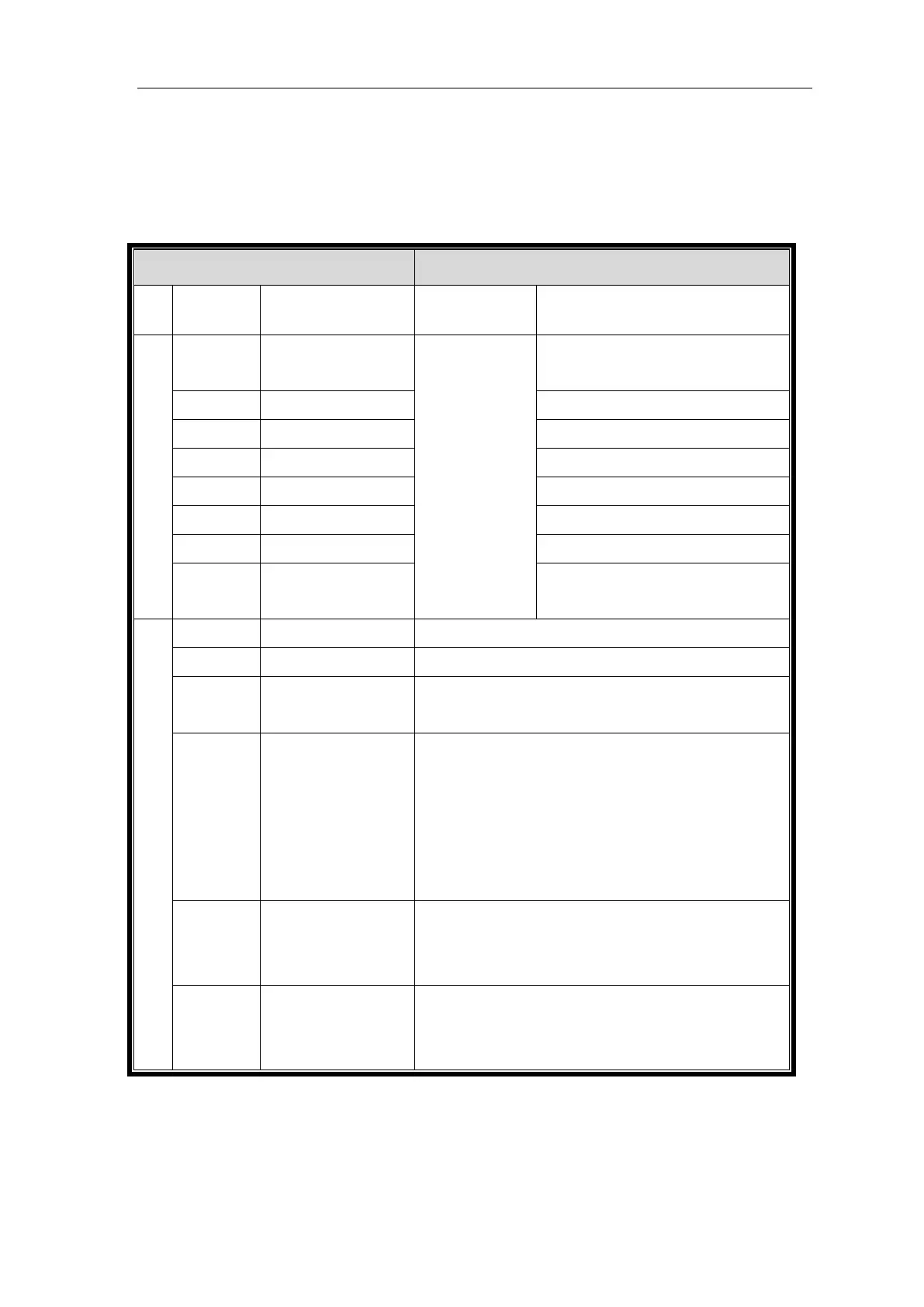

4 Parameter Need to set before Inspection Run

Note: Parameters must be saved after setting operation, otherwise the original value will be saved

after power off.

FIGURE 4.1 Parameter Need to set before Inspection Run

In blue-light

machine input,

these parameters

can generate

automatically, see

instructions below

for detail.

0: Sync machine,1: async machine. Fill in

according to actual situation.

PG card type (0: Incremental encoder, 1:

Sine/Cosine encoder)

Manual Input based on Site Condition

Motor speed at elevator rated speed (calculated)

Only for asynchronous machine; no need to set synchronous

machine. Normally set for 25%-40% of rated current.

Only for asynchronous machine; No need to set synchronous

machine. Setting according to actual situation. Calculation

method: Rated Slip = rated frequency -(rated speed * pole

pairs/60). e.g.: The motor rated slip is50-(1440*2/60)=2Hz,

when motor frequency is 50Hz, rated speed is 1440rmp, and

motor type is four-pole motor.

DirSel (direction select)

Select according to the motor installation direction in actual

situation, Select motor running direction

(0/1: Motor rotates anti- clockwise, car move down/up).

Load Compensation: 1 enable; 0 Unable. If use incremental

encoder set this to 1; If use 1387 encoder at no-weighing

mode, set this to 0.

When using Blue-Light Integrated Controller, if the traction machine is also made by Blue-Light,

you only need to input the machine model number and encoder information on the machine name

plate to finish the parameter setting of the machine.

Loading...

Loading...