Revised 5/14/2020

Air Evacuation

8

Refrigerant handling:

Leak Test, Evacuation, and Refrigerant Charging

Tools needed:

Procedure:

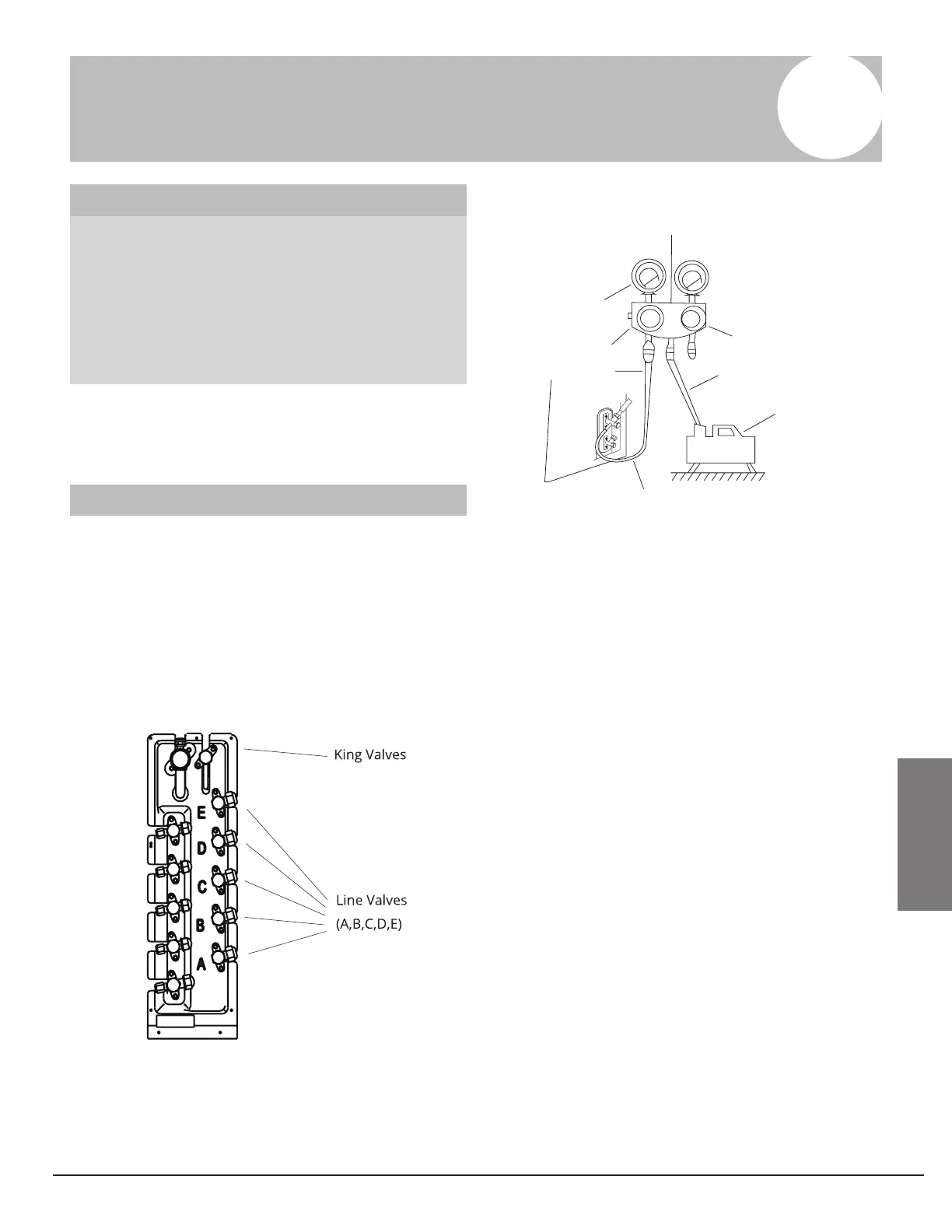

1. Open King valves (see Fig. 9.1) Open both

King Valves fully until you hit the stopper.

Do not force.

2. Connect gauges Connect low pressure mani-

fold gauge hose to mini-split adapter; connect

mini-split adapter to low pressure lineset

valve A (see Fig. 9.2).

• Dry nitrogen tank and regulator

• R410a manifold gauge set

• 1/4" to 5/16" mini-split gauge adapter

(yellowjacket)

• Soap bubble solution sprayer

• Micron gauge

• Vacuum pump

3. Pressure test Connect nitrogen tank regu-

lator to charging hose on manifold gauges.

Pressurize lineset to 200 psi of dry nitrogen.

4. Check for leaks Spray soap bubbles on t-

tings at outdoor and indoor units to check for

bubbles/ leaks. If leaks are present, retorque

are nut. If leak is still present, release nitro-

gen, inspect and re-work are. Repeat. Once

there are no leaks, proceed to step 6.

5. Discharge nitrogen pressure from lineset A

and disconnect nitrogen tank.

6. Evacuate lines Connect micron gauge and

vaccum pump to the line valve A as shown in

Fig. 9.2.

7. Vacuum lineset to below 500 microns. Once

micron gauge slows to a stop (usually 200 -

400 microns) , close manifold valve and turn

o vacuum pump.

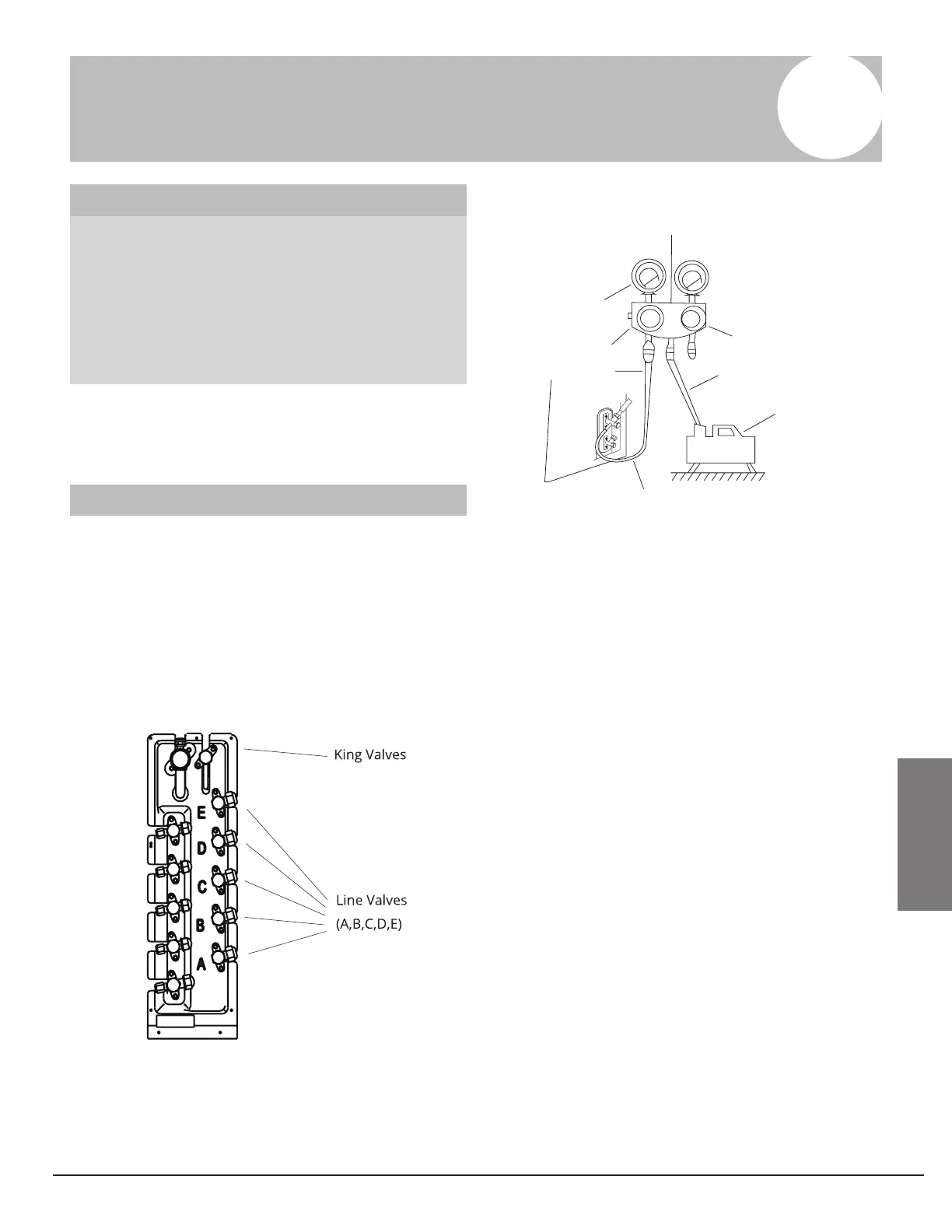

Manifold Gauge

Compound gauge

-76cmHg

Low pressure valve

Charge hose

High pressure valve

Charge hose

Vacuum pump

Pressure gauge

Page 20

Fig 9.1

Fig 9.2

Loading...

Loading...