32

8.1 - ROUTINE MAINTENANCE

Keep the gear unit at its maximum efficiency by following the routine maintenance schedule.

Good maintenance ensures the unit’s maximum performance, extended service life and conti

-

nued compliance with safety regulations.

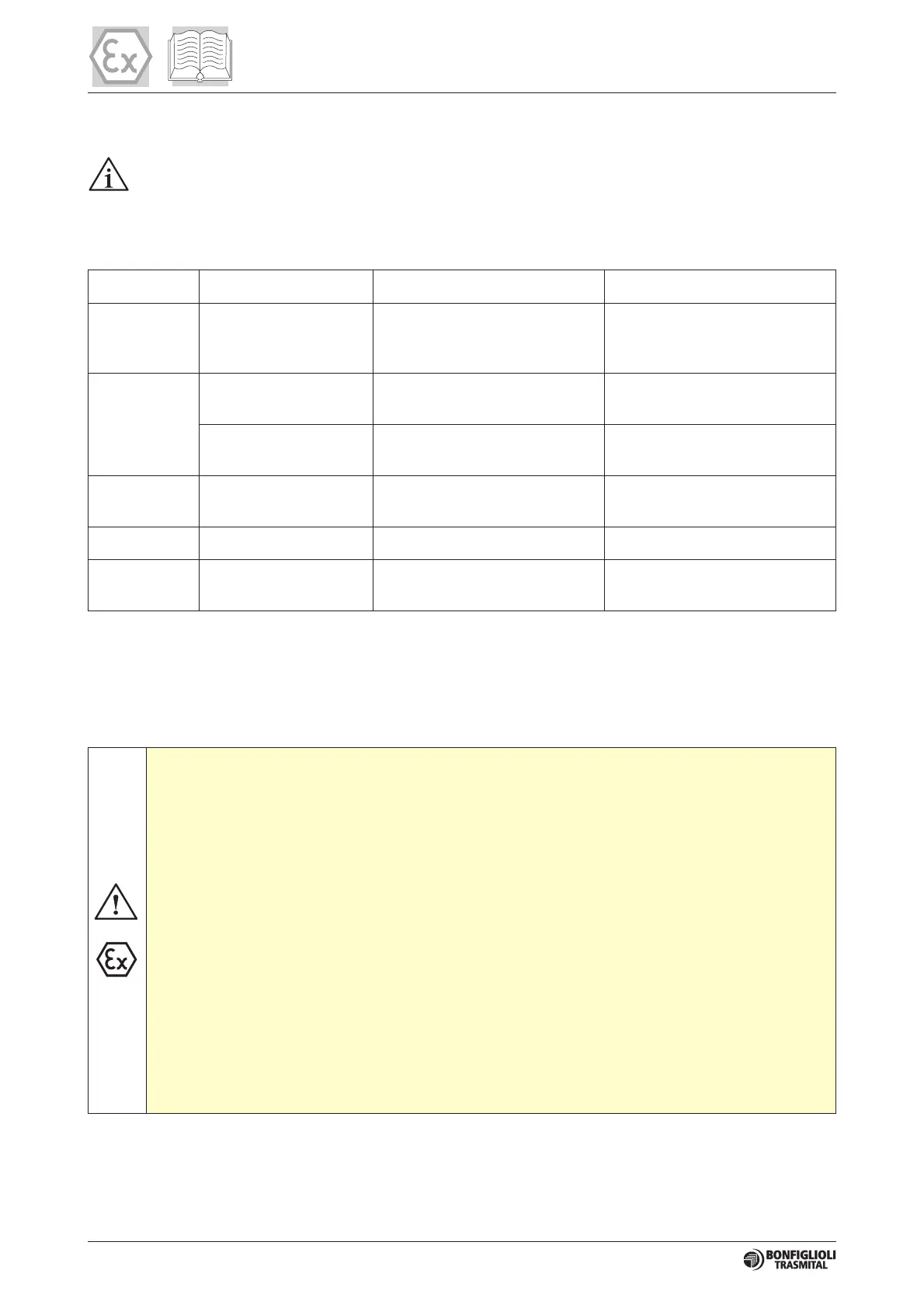

Frequency Component Type of check Action

at start Gear unit casing

Check that the external

temperature does not exceed

75-80 °C

Stop the machine and contact

Bonfiglioli Trasmital’s Technical

Service

after 200 hrs

Original consignment

lubricant

Replace Replace with new lubricant

External fasteners Check locking torque

Tighten down to specified

torque

1000 hrs

External seals and

gaskets

Check oil level

Check for leaks by eye

Service or replace components

as required

2500 hrs Lubricant Replace Replace with new lubricant

5000 hrs

Gear unit seals and

gaskets

Inspect carefully for wear/age-

ing of external seals

Replace if aged/worn

For installations in zones 21 and 22 the User must schedule and implement a regular clea-

ning programme for all surfaces and recesses to avoid dust build-ups of more than 5 mm

in depth.

Every 1000 hrs. of operation or after 6 months:

•

Measure the surface temperature at the coupling between the gear unit and motor, and at the

points which are most shielded from the motor’s cooling fan. The maximum temperature must

not be more than 75-80°C, nor may this value be exceeded during operation.

Every 5000 hrs. of operation:

•

Change the synthetic oil and bearing grease if the gear unit is not life lubricated.

•

Replace all externally accessible seal rings unless this has already been done as a result of

problems occurring before the scheduled maintenance deadline.

(A3)

Loading...

Loading...