Installing the solar pump station | 11

6 720 811 270 (2015/04)AGS10-2, AGS10E-2, AGS20-2, AGS50-2

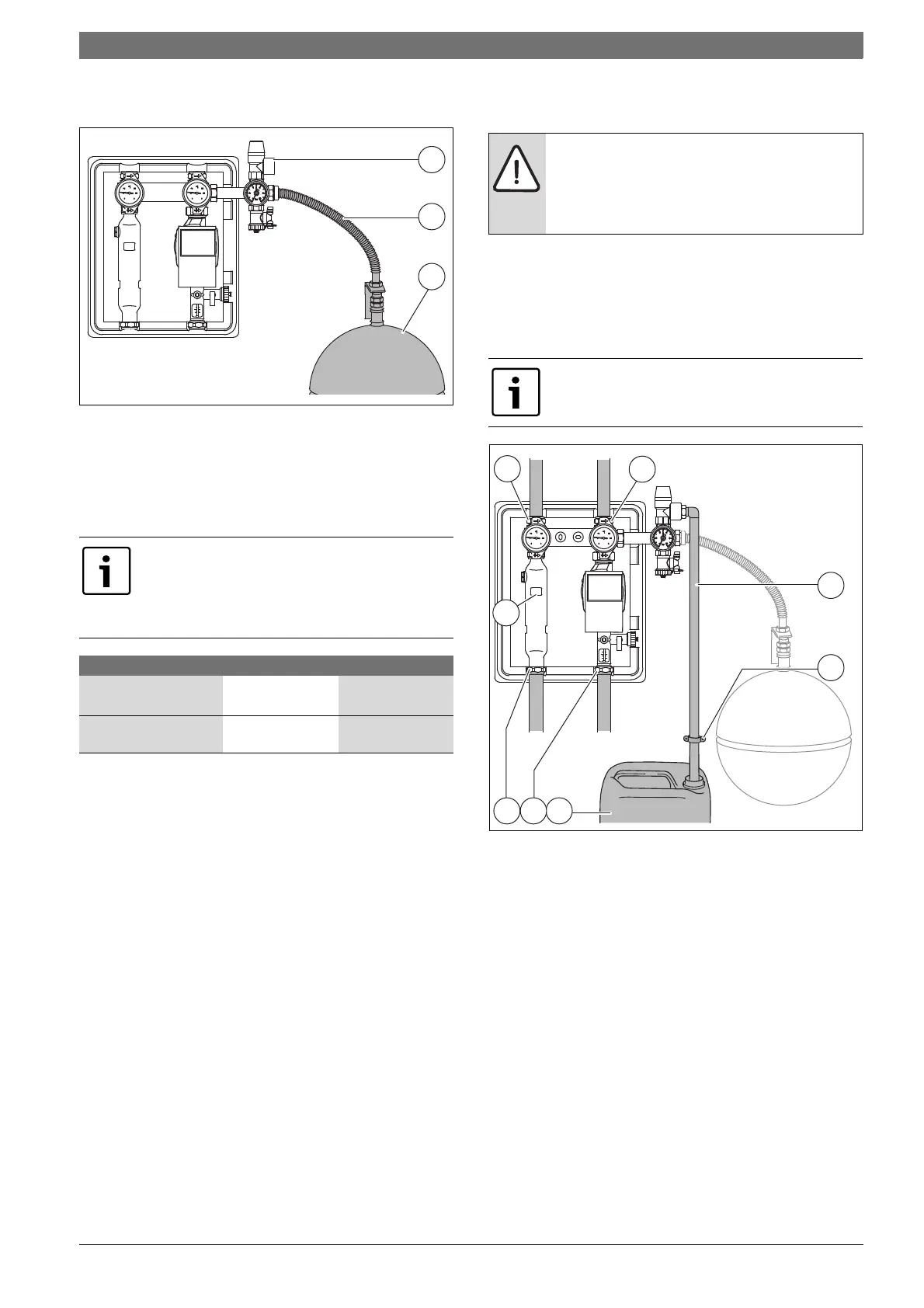

▶ Connect the expansion vessel [3] in the return on the solar pump

station's safety assembly.

Fig. 16

[1] Pressure relief valve

[2] Flexible stainless steel hose from the connection set (available as

accessory)

[3] Expansion vessel

5.5.3 Adjusting the pre-charge pressure of the expansion vessel

To make use of the maximum possible volume:

▶ Set the pre-charge pressure when the vessel is not subjected to load

(i.e. no fluid pressure).

▶ If the calculated pre-charge pressure is higher or lower than the

factory-set pre-charge pressure (see table 7, page 11), correct the

pre-charge pressure accordingly.

5.6 Connecting pipework and pressure relief valve

discharge pipe to the solar pump station

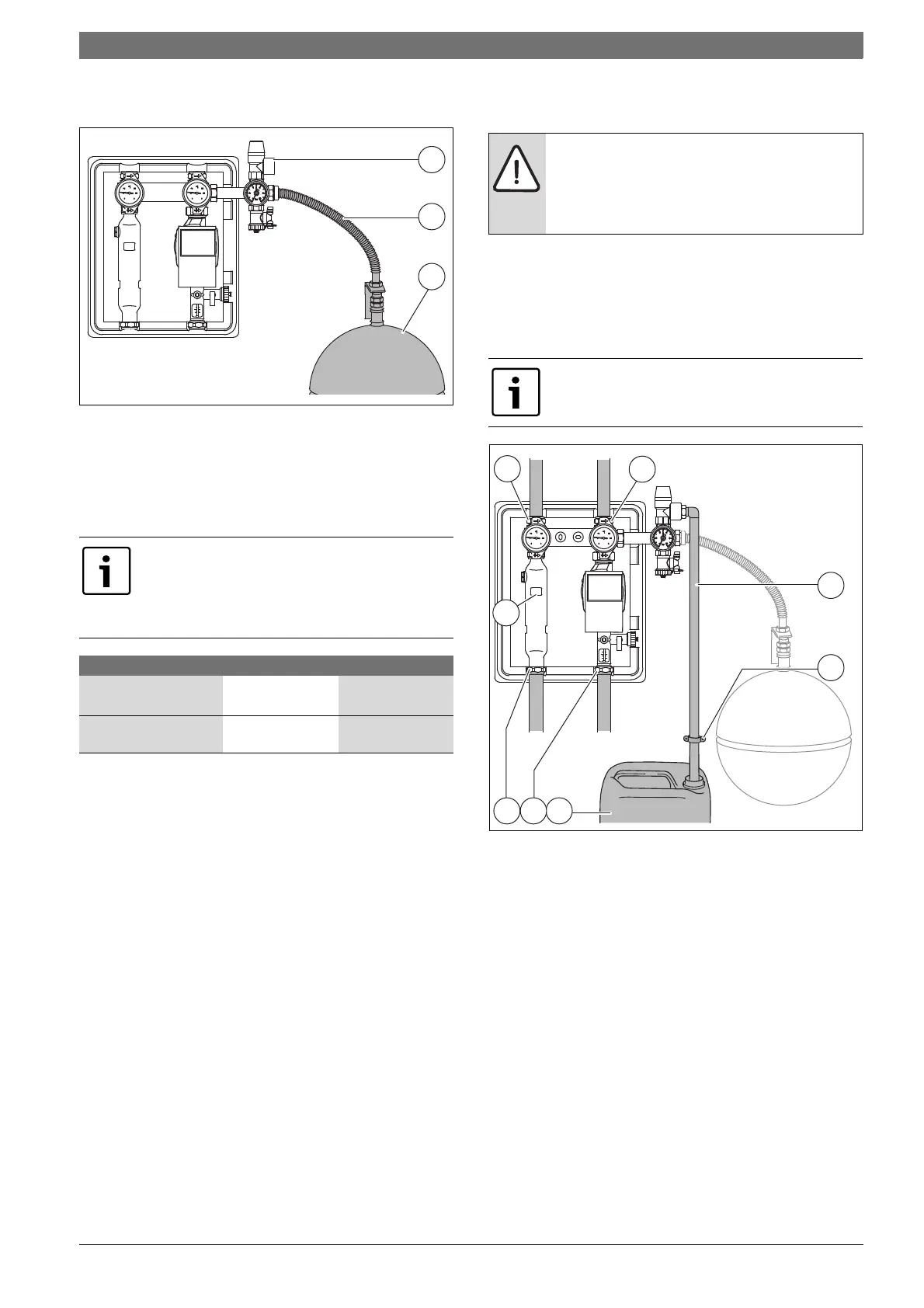

▶ Cut the pipes to length and push them as far as possible into the

compression fitting [1].

▶ Route the discharge pipe [2] from the pressure relief valve so that any

discharge can be seen to empty out into the holding container [4] and

secure it in place with a pipe clip [3].

▶ Maintain an air break.

Fig. 17 Connection to solar pump station

[1] Compression joints on all four outlets

[2] Discharge pipe (not supplied)

[3] Pipe clip (on site)

[4] Empty solar fluid container (holding container)

[5] Connection bracing points

The pre-charge pressure of the expansion vessel is

calculated based on the static system head

1)

plus an

allowance.

▶ Calculate and set pre-charge pressure to at least

1.2 bar.

Flat plate Evacuated tube

Static height

1)

1) A one metre difference in height (between collector array and solar pump station)

equates to 0.1 bar

(10 m) 1.0 bar (10 m) 1.0 bar

+ allowance + 0.4 bar + 1.7 bar

= expansion vessel pre-

charge pressure

= 1.4 bar = 2.7 bar

Table 7 Example: collector-dependent pre-charge pressure

WARNING: Injuries and system damage due to hot heat

transfer medium.

▶ Make sure the discharge pipe size is at least that of the

pressure relief valve (maximum length = 2 m and

maximum of 2 bends).

To tighten the lower compression fittings, you can brace

against the points marked [5] using a 27 mm spanner or

pipe wrench.

7747006489.49-2.ST7747006489.49-2.ST

3

141

1

1

2

5

Loading...

Loading...