5

EP Series

8733922168

Revised 12-13 Subject to change without prior notice

connections, allowing easy removal of the access

panels, and replacement of air lters for routine

maintenance. This will ensure proper work space for

service personnel to perform maintenance or repair.

See Unit Specications for replacement lter sizes

in the back of this manual to ensure proper

clearances are provided during installation. Allow

adequate room below the unit for a condensate

drain trap on horizontal units.

Water freezes at 32°F. Frozen water coils are not

covered under the limited product warranty. It is

the installer’s responsibility to insure that the heat

pump unit is installed in a location or have taken

the proper precautions in order to prevent

rupturing the water coil due to freezing conditions.

The heat pump unit is designed for conditioned

space installation only. If the source water is

subjected to conditions where ambient

temperatures can fall below freezing, some form of

freeze protection should be employed. In an open

loop system this may entail running the water pump

continuously to prevent freezing. An antifreeze

solution wherever possible should be used if water

will be subject to freezing. Consult the factory in

these instances for guidance.

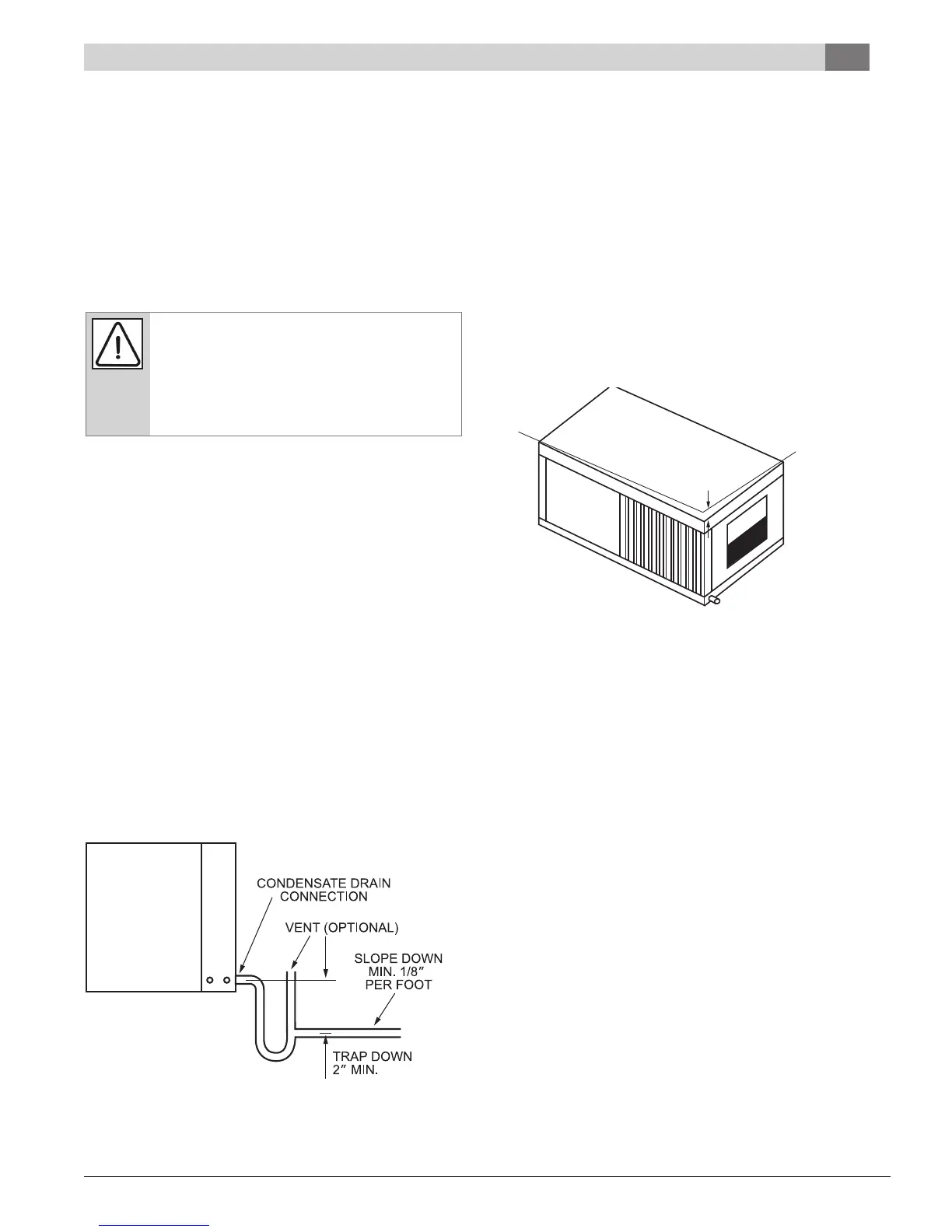

CONDENSATE DRAIN

A drain line must be connected to the heat pump

and pitched away from the unit a minimum of 1/8”

per foot to allow the condensate to ow away from

the unit.

Figure #3— Heat pump condensate trapping

This connection must be in conformance with local

plumbing codes. A trap must be installed in the

condensate line to insure free condensate ow.

(Heat Pumps are not internally trapped). A vertical

air vent is sometimes required to avoid air pockets

(See Figure #3). The length of the trap depends on

the amount of positive or negative pressure on the

drain pan. A second trap must not be included.

The horizontal unit should be pitched

approximately 1/4” towards the drain in both

directions, to facilitate condensate removal. See

Figure 4 below.

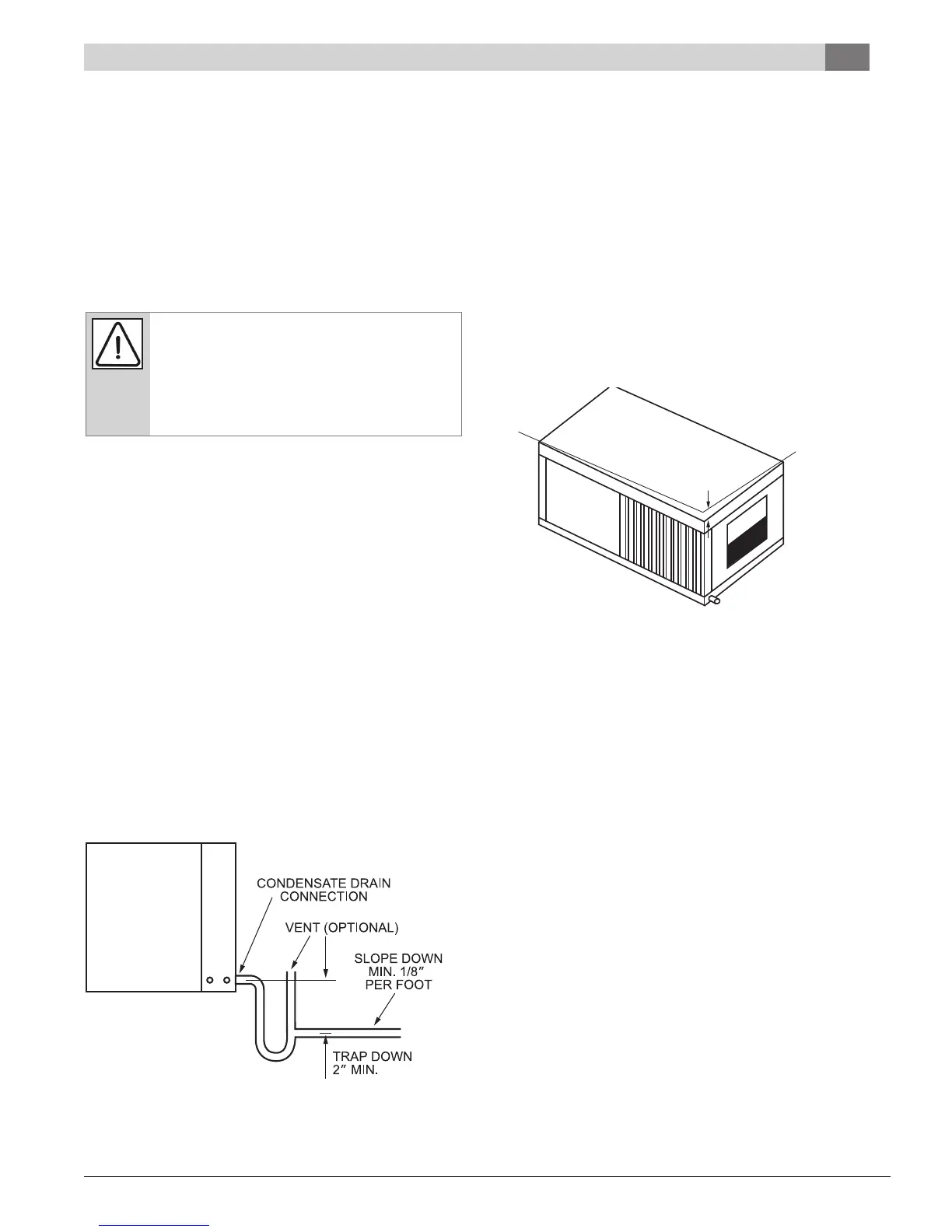

Figure #4 – Sloped horizontal unit installation

DUCT SYSTEM

A supply air outlet collar and return air duct ange

are provided on all units to facilitate duct

connections. See Unit Specications for duct collar

connection sizes in the back of this manual.

A exible connector is recommended for supply

and return air duct connections on metal duct

systems. All metal ducting should be insulated with

a minimum of one inch duct insulation to avoid heat

loss or gain and prevent condensate forming during

the cooling operation. Application of the unit to

uninsulated duct work is not recommended as the

unit’s performance will be adversely affected. Do

not connect ducts directly to the blower outlet;

factory supplied duct collars should be used for the

connection to minimize unit vibration and noise

transmission to the ductwork and ultimately into

the conditioned space. The factory provided air

lter must be removed when using a lter back

return air grill. The factory lter should be left in

place on a free return system.

ELEVATION LINE

WHEN MOUNTED LEVEL

1/4″

Condensate Drain

Loading...

Loading...