Table 2.1:

Maximum detection range

NOTICE!

Manual mode is active for 20 minutes

after power up.

NOTICE!

Cycle the sensor power after

changing switch settings.

NOTICE!

Do not use double-sided tape or

RTV which reduces vibration.

5 | Adjust potentiometer

Fine tune the sensitivity level by turning

the potentiometer clockwise to increase

sensitivity or counter-clockwise to decrease

sensitivity. During Self-learning mode, adjust

the potentiometer until the sensor LED turns

off, indicating that the sensor is correctly

configured.

Figure 5.1: Sensitivity potentiometer

– +

4 | Switch settings

The switch settings change sensor

configuration or sensitivity.

Figure 4.1: Switches

Switches 1 and 2 - sensitivity level setting.

Refer to sections 6 and 7 for configuring

these switch settings during installation.

Switch

Sensitivity Level

1 2

OFF OFF Low (default - least

sensitive)

OFF ON Low-medium

ON OFF High-medium

ON ON High (most sensitive)

4.2 | Set pulse count

Switch 4 Drill/saw detection

ON Disabled

OFF Enabled (default)

Switch 4 - drilling or sawing detection

setting.

4.5 | Set installation mode

Switch 6 - Manual or Self-learning mode

setting.

Switch 6 Installation mode

ON Self-learning mode

OFF Manual mode (default)

LED Condition

Green flash Vibration, movement,

contact or attack attempt

or during configuration.

Red on 2 seconds Alarm

Red on steady Sensor fault, sensor

position changed from

original installation.

Switch 5 LED function

ON Enabled (default)

OFF Disabled

Switch 3 Pulse count

ON 4 pulses

OFF 1 pulse (default)

4.3 | Set drill/saw detection

Switch 3 - pulse count setting. The sensor

generates an alarm when noise occurs

within the pulse count. When set to ON

the alarm triggers on 4 pulses within 40

seconds (15 seconds - 10 seconds - 15

seconds). When set to OFF, the alarm

triggers on the first pulse.

4.4 | Set LED

Switch 5 - LED setting. Do not disable this

setting during installation.

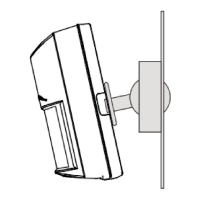

3 | Installation

Mounting the base:

1. Identify mounting location and surface.

2. Remove or drill through the mounting

holes in the base.

3. Insert the screws into the mounting

holes or use glue to secure the base to

the surface.

Figure 3.1: Unlocking and opening cover

1. Insert a slotted screwdriver into the

rotary lock on the front of the sensor

and turn counter-clockwise to the open

position (unlocked).

2. Pull apart the sensor from the top to

remove the cover from the base.

Figure 3.2: Screw locations

3.1 | Wiring

1. Insert the wire through the grommet

(removable). Refer to Figure 3.3.

2. Attach wire to the appropriate terminals.

Tamper and Alarm Contact normally-

closed (NC), Power 12VDC. Refer to Figure

3.4.

Figure 3.3: Wiring

Figure 3.4: Terminal

– Install the ISC-SK10 indoors and mount

on a variety of flat surfaces.

– Use the included screws or an adhesive

glue to secure the unit to the surface.

2 | Installation considerations

4.1 | Set sensitivity level

Surface Radius (m) Radius (ft)

Concrete 1.5 5

Brick wall 2.5 8

Steel 3 10

Wood 3.5 11.5

Glass 3.5 11.5

The ISC-SK10 is an advanced shock sensor

designed to monitor and detect mechanical

attacks.

Callout ― Description

1 ― LED

2 ― Potentiometer (sensitivity adjustment)

3 ― Cover tamper

4 ― Terminal block

5 ― Switches

Figure 1.1: ISC-SK-10 overview

32

5

1

4

1 | Overview

Loading...

Loading...