22 | English

(14)

Transfer bucket

a)

(15)

Nozzle needle

(16)

Container seal

(17)

Suction tube

(18)

Ventilation hole

(19)

Paint channel

(20)Air hose

(21)

Bayonet lock

(22)Base unit

(23)

Carrying handle

(24)

Holding clamp

(25)

On/off button with air flow control

(26)

Hose port (base unit)

(27)

Accessory compartment

(28)

Cleaning brush

(29)

Air filter cover

(30)

Air filter

a)

Accessories shown or described are not included with the

product as standard. You can find the complete selection of

accessories in our accessories range.

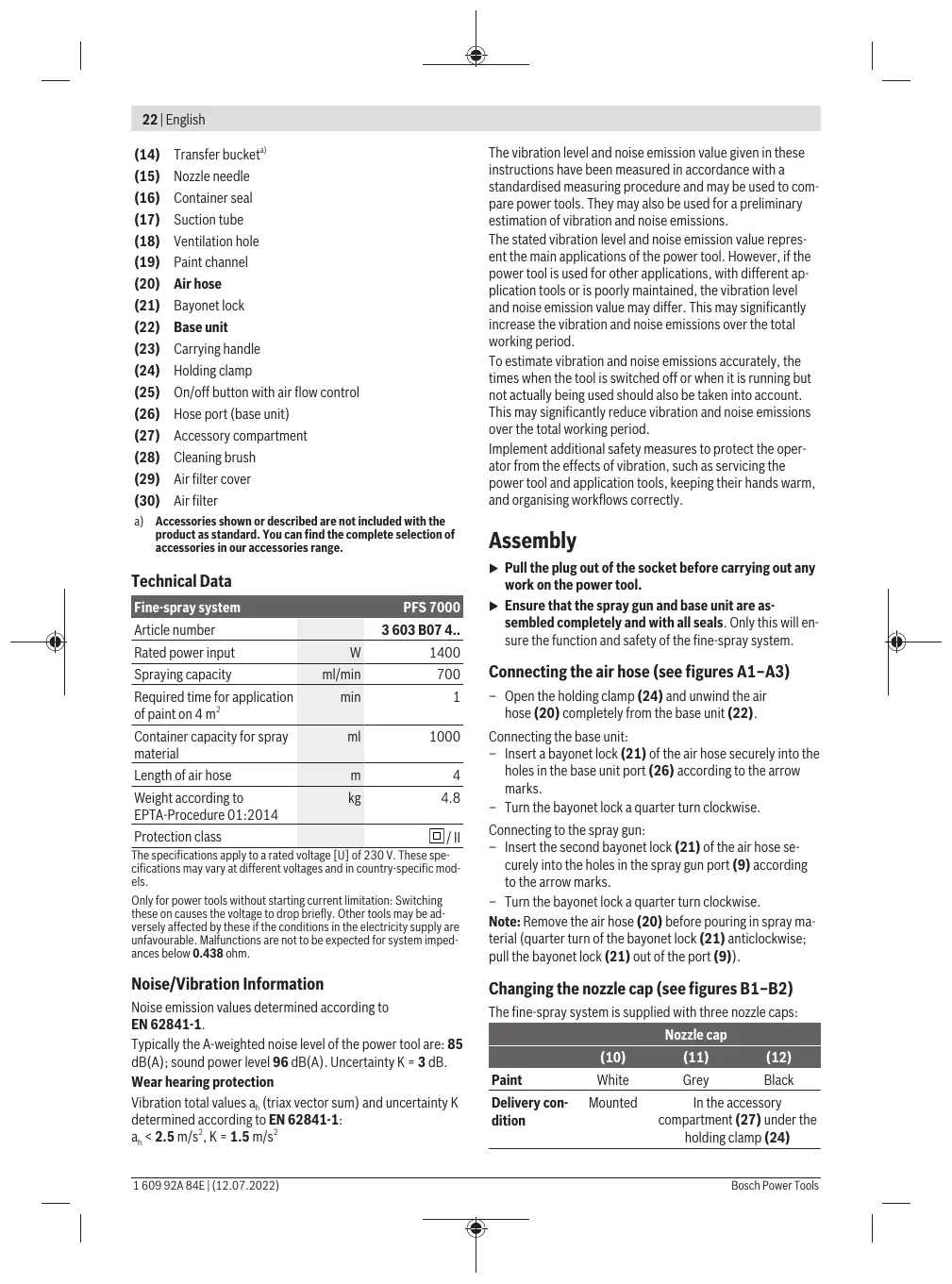

Technical Data

Fine-spray systemPFS7000

Article number

3 603 B07 4..

Rated power inputW1400

Spraying capacityml/min700

Required time for application

of paint on 4m

2

min1

Container capacity for spray

material

ml1000

Length of air hosem4

Weight according to

EPTA-Procedure01:2014

kg4.8

Protection class

/ II

The specifications apply to a rated voltage [U] of 230 V. These spe-

cifications may vary at different voltages and in country-specific mod-

els.

Only for power tools without starting current limitation: Switching

these on causes the voltage to drop briefly. Other tools may be ad-

versely affected by these if the conditions in the electricity supply are

unfavourable. Malfunctions are not to be expected for system imped-

ances below0.438ohm.

Noise/Vibration Information

Noise

emission values determined according to

EN62841-1.

Typically the A-weighted noise level of the power tool are: 85

dB(A); sound power level 96 dB(A). Uncertainty K = 3 dB.

Wear hearing protection

Vibration total values a

h

(triax vector sum) and uncertainty K

determined according to EN62841-1:

a

h

<2.5m/s

2

, K=1.5m/s

2

The vibration level and noise emission value given in these

instructions have been measured in accordance with a

standardised measuring procedure and may be used to com-

pare power tools. They may also be used for a preliminary

estimation of vibration and noise emissions.

The stated vibration level and noise emission value repres-

ent the main applications of the power tool. However, if the

power tool is used for other applications, with different ap-

plication tools or is poorly maintained, the vibration level

and noise emission value may differ. This may significantly

increase the vibration and noise emissions over the total

working period.

To estimate vibration and noise emissions accurately, the

times when the tool is switched off or when it is running but

not actually being used should also be taken into account.

This may significantly reduce vibration and noise emissions

over the total working period.

Implement additional safety measures to protect the oper-

ator from the effects of vibration, such as servicing the

power tool and application tools, keeping their hands warm,

and organising workflows correctly.

Assembly

u Pull the plug out of the socket before carrying out any

work on the power tool.

u Ensure that the spray gun and base unit are as-

sembled completely and with all seals. Only this will en-

sure the function and safety of the fine-spray system.

Connecting the air hose (see figuresA1–A3)

–Open the holding clamp(24) and unwind the air

hose(20) completely from the base unit(22).

Connecting the base unit:

–Insert a bayonet lock(21) of the air hose securely into the

holes in the base unit port(26) according to the arrow

marks.

–Turn the bayonet lock a quarter turn clockwise.

Connecting to the spray gun:

–Insert the second bayonet lock(21) of the air hose se-

curely into the holes in the spray gun port(9) according

to the arrow marks.

–Turn the bayonet lock a quarter turn clockwise.

Note: Remove the air hose(20) before pouring in spray ma-

terial (quarter turn of the bayonet lock(21) anticlockwise;

pull the bayonet lock (21) out of the port (9)).

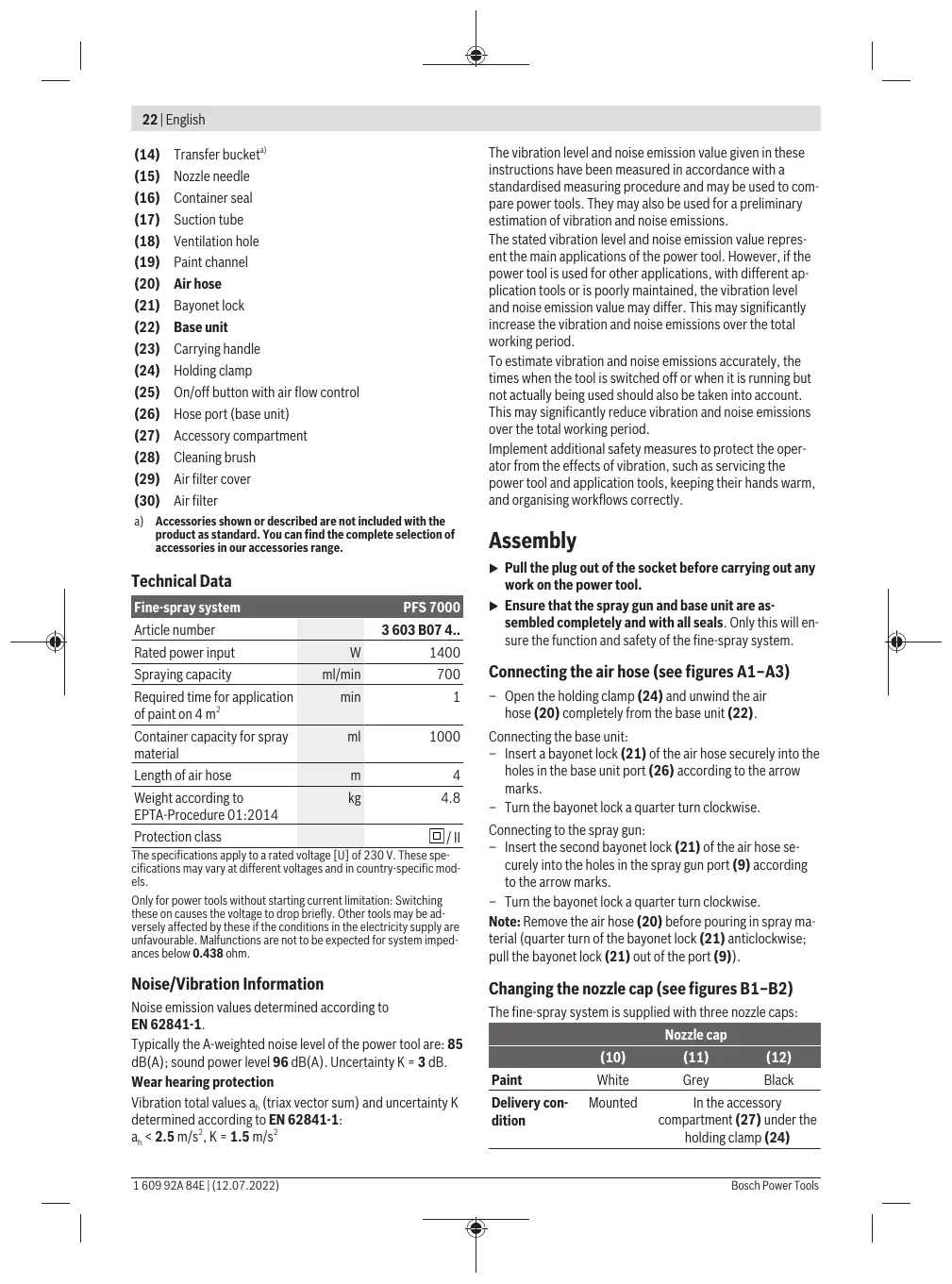

Changing the nozzle cap (see figuresB1–B2)

The fine-spray system is supplied with three nozzle caps:

Nozzle cap

(10)(11)(12)

Paint

WhiteGreyBlack

Delivery con-

dition

MountedIn the accessory

compartment(27) under the

holding clamp(24)

1 609 92A 84E | (12.07.2022)Bosch Power Tools

Loading...

Loading...