English | 31

Bosch Power Tools 1 609 92A 3VE | (15.5.17)

Assembly

Avoid unintentional starting of the machine. During as-

sembly and for all work on the machine, the power plug

must not be connected to the mains supply.

Delivery Scope

Please also observe the representation of the

delivery scope at the beginning of the operat-

ing instructions.

Before starting the operation of the machine

for the first time, check if all parts listed below

have been supplied:

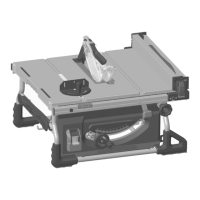

–Table saw

(Preassembled: Table width enlargement 10, saw blade

37, insert plate 3)

– Bottom plate 34 with pre-mounted cross-head screws

– Table extension 2

– Fastening kit for “table extension”39

(2 guide rods, 2 securing screws, 2 clips, 2 short fastening

knobs)

– Parallel fences 8 and 9

– Auxiliary stops 7 and 18

–Angle stop 16

– Fastening kit “for auxiliary stop/angle stop” 43

– Blade guard 5,

Riving knife 4 with pre-mounted hexagon bolt 35

–Vacuum hose 33

–Push stick 22

– Ring spanner 17

for machine versions with base unit:

PTS 10 T, PTS 100 T:

–Base unit 67

(12 Profiles, 4 end caps)

– Fastening kit for base unit 66

(24 screws with nuts for assembly, 4 screws with nuts for

fastening of the machine, 4 washers)

Note: Check the power tool for possible damage.

Before further use of the machine, check that all protective

devices are fully functional. Any lightly damaged parts must

be carefully checked to ensure flawless operation of the tool.

All parts must be properly mounted and all conditions fulfilled

that ensure faultless operation.

Damaged protective devices and parts must be immediately

replaced by an authorised service centre.

Initial Operation

– Carefully remove all parts included in the delivery from

their packaging.

– Remove all packaging material from the machine and the

accessories provided.

– Take care that the packaging material under the motor

block es removed.

Additionally required tools (not in delivery scope):

– Cross-head screwdriver

–Angle gauge

– Box-end or open-end spanner (size 13 mm)

for assembly of the base unit

Assembly Sequence

For easier working, observe the assembly sequence of the

supplied product features.

1. Assembly from Below

–Vacuum hose 33

– Bottom plate 34 with pre-mounted cross-head screws

2. Assembly from Above

– Riving knife 4

– Table extension 2

–Angle stop 16 and auxiliary stop 18

– Parallel guide 8 and auxiliary stop 7

Assembly from Below

– Turn the machine around so that it is upside down on the

saw table 11.

Mounting the Vacuum Hose (see figure a)

– Connect the chip ejector on the saw blade casing and the

chip ejector 31 on the machine housing with the vacuum

hose 33.

Mounting the Bottom Plate (see figure b)

– Insert the bottom plate 34 into the intended recesses so

that the cross-head screws can be screwed into the holes

of the housing.

– Fasten the bottom plate by screwing in and tightening the

cross-head screws.

Assembly from Above

– Turn the power tool over so that it is back in the correct po-

sition for working.

Mounting the Riving Knife (see figures c1–c3)

– Using the ring spanner 17, lift up the insert plate 3 at the

front and remove it from the notches 36.

–Turn the crank 12 counter-clockwise until it stops, so that

the saw blade 37 is positioned as high as possible over the

saw table.

– Loosen locking knob 29 to tilt the saw blade 37.

– Insert the riving knife 4 so that the respective holes are po-

sitioned on the guide bolts of the riving knife fixture 38.

– Fasten the riving knife 4 to fixture 38 by firmly tightening

hexagon bolt 35 with ring spanner 17 (13 mm).

– Readjust the saw blade back to 90° again and tighten lock-

ing knob 29. (also see “Adjusting Bevel Angles”, page 33)

Note: The riving knife must be in alignment with the saw blade

to avoid jamming of the workpiece.

– Finally, reassemble the insert plate 3.

For this, hook the insert plate into the notches 36 and then

press the insert plate downward until it engages in the saw

table.

– Tighten the nut of the blade guard sufficiently with the ring

spanner 17 (13 mm) so that the blade guard remains se-

cured in any set position.

Mounting the Table Extension (see figures d1–d2)

For assembly, use the fastening kit for “table extension” 39.

(2 guide rods, 2 securing screws, 2 clips, 2 short fastening

knobs)

OBJ_BUCH-783-008.book Page 31 Monday, May 15, 2017 2:42 PM

Loading...

Loading...