Commissioning

Greenstar Danesmoor Kitchen

ErP+

and Kitchen System

ErP+

-6 720 821 686 (2018/04)44

6.4.6 Combustion checks

▶ Start and run the boiler for 20 minutes.

▶ Remove the sampling point plug [1] to check the smoke reading is

between 0-1. If the smoke level is above 1, check the combustion

settings are correct and the oil nozzle is in good condition.

Fig. 74

▶Check the CO

2

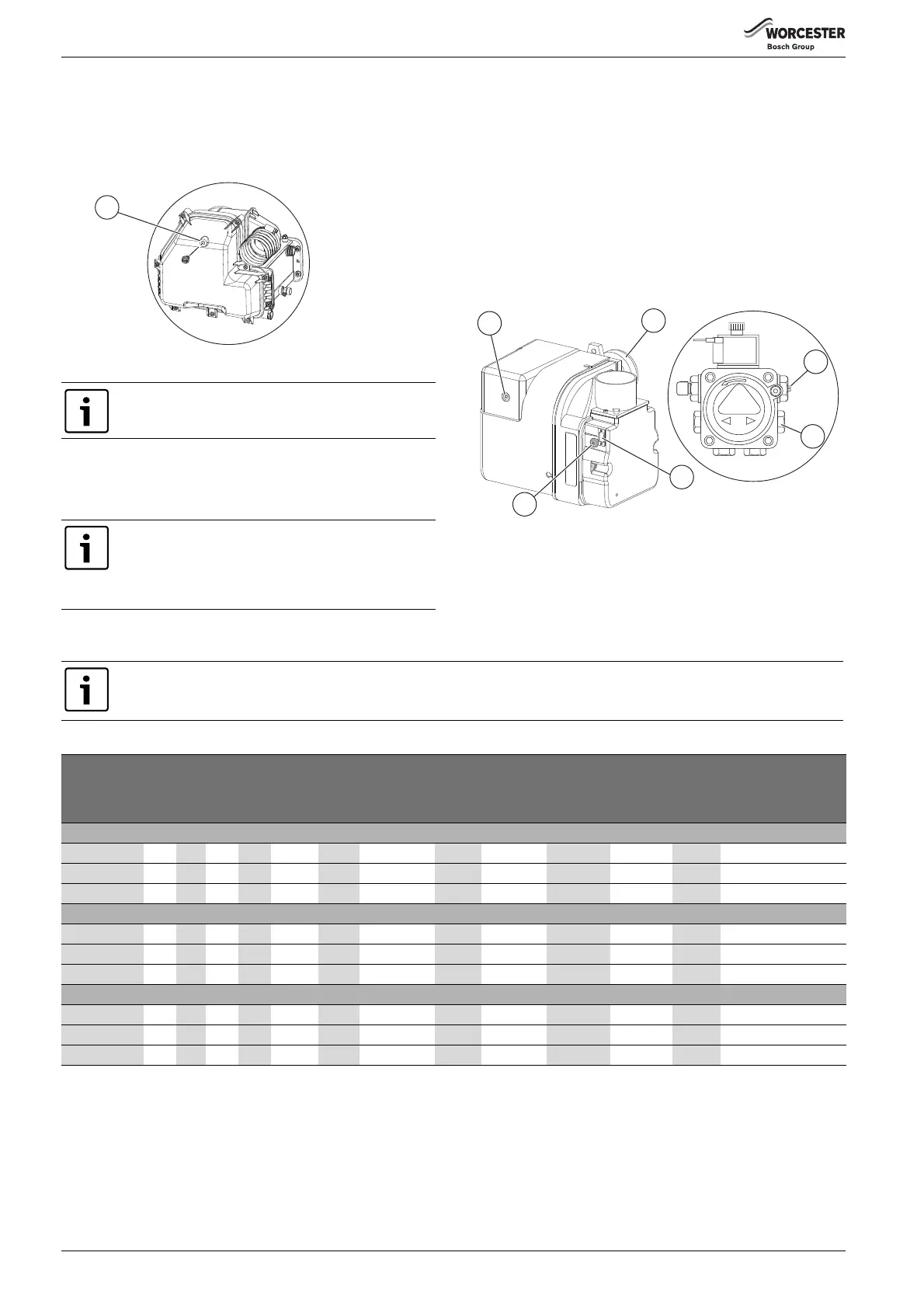

levels and adjust the air shutter [6] figure 75 setting

according to the table opposite.

▶ Check the flue gas temperature is close to the values shown in the

table 10 on page 44.

▶ Turn off the electrical supply.

▶ Isolate the oil supply to the burner.

▶ Remove the oil pressure gauge.

▶ Refit the blanking plug [4] figure 75.

▶ Check and rectify any oil leaks.

▶ Switch on the oil supply.

▶ Switch on the electrical supply.

▶ Restart the boiler and run for five minutes.

▶ Recheck the CO

2

levels and if required, adjust the air shutter setting

[6] figure 75 to obtain the correct CO

2

level.

▶ Refit the sample point cap (hand tighten only, do not over tighten)

and refit the burner cover.

Fig. 75

[1] Lockout feset button

[2] Combustion head

[3] Pressure adjustment

[4] Bleed and pressure gauge port

[5] Air shutter display window

[6] Air shutter adjuster

Nominal boiler rating at normal operating temperature using Kerosene (Class C2)

Smoke readings may be inaccurate until the smoke from

the burning organic binder in the access door insulation

has ceased.

If the flue gas temperature is too high and the baffles are

correctly fitted, then reduce the oil pump pressure [3]

fig. 75, 5-10 p.s.i. to compensate for nozzle variations.

If the pump pressure has been changed, the CO2 levels

must be rechecked and air shutter adjusted if necessary.

6720809437-35.1Wo

1

APPLIANCE MUST BE SET TO CO

2

LEVELS.

AIR SETTINGS GIVEN ARE APPROXIMATE ONLY, AS FLUE LENGTH AND NOZZLE VARIATIONS WILL AFFECT THIS.

Oil pump

pressure

Fuel flow

rate

Approx

flue gas

temp.

Combustion

head settings

Approx.

air

setting

Input

(appliance)

Output

(appliance)

Air damper

disc

setting

Flue

damper

required

Burner head

Nozzle bar psi Kg/h l/h °C %CO2 mm kW kW

Greenstar Danesmoor 12/18 model

0.40 x 80° EH

8.5 123 1.12 1.38 67 12.0 10.5 2.3 13.2 13.0 A Yes BX & recirculation tube

0.40 x 80° EH

10.0 145 1.30 1.60 70 11.5 11 1.75 15.3 15 B Yes BX & recirculation tube

0.50 x 80° EH

10.0 145 1.54 1.90 80 12.0 11.5 2.5 18.3 18.0 C Yes BX & recirculation tube

Greenstar Danesmoor 18/25 model

0.50 x 80° EH

10.0 145 1.54 1.90 76 12.5 12.5 1.5 18.3 18.0 N/A Yes BX

0.60 x 60° EH

8.8 128 1.84 2.28 81 12.5 14 3.25 21.9 21.5 N/A Yes BX

0.65 x 80° EH

9.5 138 2.15 2.66 90 12.5 15 3.25 25.5 25.0 N/A Yes BX

Greenstar Danesmoor 25/32 model

0.65 x 80° EH

9.8 142 2.15 2.66 79 11.5 19 3.5 25.5 25.0 N/A No BX

0.75 x 80° EH

10.3 150 2.46 3.04 84 12.0 19 4.25 29.1 28.5 N/A No BX

0.85 x 80° EH

10.0 145 2.78 3.44 85 12.5 19 4.75 32.7 32.0 N/A Yes

1)

1) Internal boilers with flues less than 4 metres

BX

Table 10 Combustion settings

Loading...

Loading...