Equipment Required:

Audio signal generator

Audio amplifi er

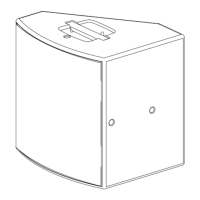

Test Connection Information

Ensure the Panel has all jumpers (green) in

place as shown. Test connections should be to

the 8 Ohm input terminals as indicated by the

red and white arrows shown in fi gure 10.

1. Phase Test

Note: All acoustic testing from 1.1 through

3.2 should be performed without the grille

attached.

1.1 Refer to disassembly procedure 1, Grille

Removal, Figures 4-5.

1.2 Place one hand on the woofer and gently

touch the dust cap or cone with fi ngers.

Momentarily apply a voltage of 8 VDC + 1

VDC, to the input terminals.

Pass: The woofer where the cone moves

outward.

Fail: The woofer where the cone does not

move outward.

2. Air Leak Test

Note: You can measure the AC input voltage

levels for the following tests at the loudspeaker

barrier strip terminals.

2.1 Apply a signal of 30 Vrms,

+ 2 Vrms, @ 40

Hz and 55 Hz to the speaker input.

2.2 Sweep the input frequency from 20 Hz to

200 Hz. 4 seconds up and 4 seconds down.

2.3 Listen carefully for air leaks at gaskets and

joints. Replace any driver that has a rubbing or

a ticking noise.

3. Rub and Tick Test

3.1 Apply a 25 Vrms, + 1 Vrms, 10Hz signal to

the speaker input.

3.2 Listen carefully for buzzes, rattles, or other

extraneous noises from the drivers or from the

enclosure.

PASS: any speaker that has no rubbing or

ticking noise.

FAIL: any speaker that has a rub, tick,

rattle, buzz, thump or any other extraneous

noise.

4. Low Frequency Sweep with Grille attached

4.1 Reattach Grille.

4.1 Slowly apply 1 Vrms, 20 Hz to 2K Hz, into

the speaker. Listen carefully for any buzzing or

rattles from the grille assembly.

4.2 Replace any speaker that has a buzzing

noise or is defective. There must not be any

buzzes, ticks, rubs, bottoming sounds, air leaks

or other unwanted acoustic noises.

Test Procedures

12

Figure 10

Loading...

Loading...