ADJUSTING THE MAGAZINE

(IC60-1-E & IC70-1-E ONLY)

1. Release the canister latch on the rear of the canister.

(Fig. 8)

2. Pull out the canister bottom by swinging right to left

until tabs disengage. (Fig. 9)

3. Inside the canister bracket there are settings in

inches and millimeters. The canister is adjusted

correctly when the length of fastener being used

isshown in the window of the canister bottom.

4. Push back the canister bottom and engage the latch

ADJUSTING THE MAGAZINE

(IC50-2-E, IC50-1-E, IC90-1-E, IC90P-1-E,

IC90C-1-E ONLY)

1. The magazine contains an adjustable nail platform

on which the nail coil rests. The nail platform can

beadjusted up and down to three nail settings.

2. To change settings, pull up on the post and twist

tothe correct step. (Fig. 10)

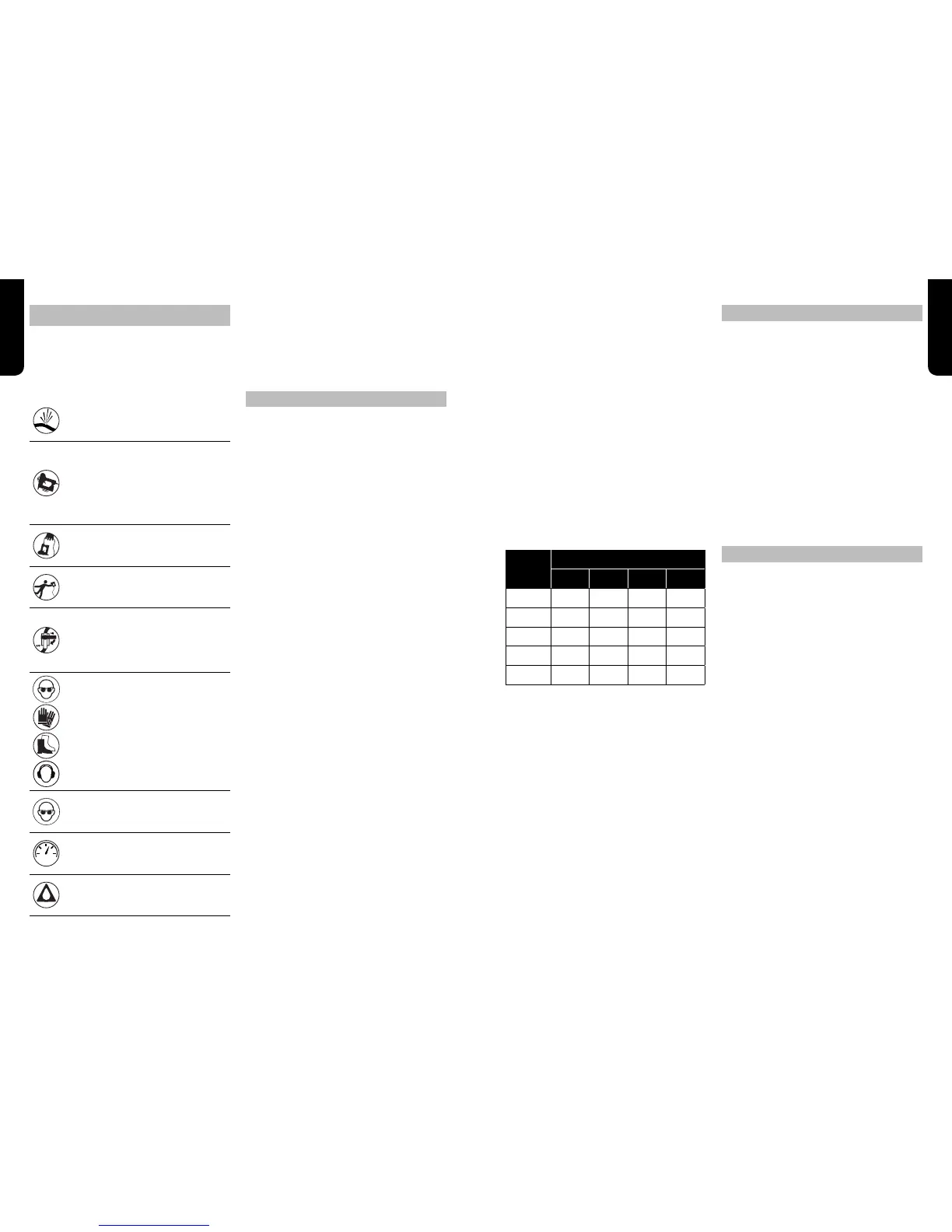

Model

Step Number / Nail Length (mm)

1 2 3 4

IC50-2-E 25-27 32 38-45 50

IC50-1-E 25-27 32 38-45 50

IC90-1-E 80-90 70-75 50-65

-

IC90P-1-E 80-90 70-75 50-65

-

IC90C-1-E 80-90 70-75 50-65

-

GUIDE ROD (IC50-2-E & IC50-1-E ONLY)

The tool includes a guide rod that needs to be adjusted

depending on the type of nails:

- The rod should be in the depressed position for

standard plastic inserted nails with 7mm pitch (Fig. 11)

- The rod should be in the released position for wire

welded nails and plastic inserted nails with 6mm pitch

(Fig. 12)

TRIP OPERATION MODE

THESE TOOLS ARE FITTED WITH 2 DIFFFERENT

ACTUATION MODES DEPENDING ON THE MODEL.

m WARNING! Always disconnect air supply before

making adjustments as accidental actuation may

occur, possibly causing injury.

SEQUENTIAL ACTUATION MODE:

Models: IC50-2-E

CONTACT ACTUATION MODE:

Models: IC50-1-E, IC60-1-E, IC70-1-E, IC90-1-E,

IC90P-1-E, IC90C-1-E

IMPORTANT: The IC90C-1-E is fitted with an

auxiliary handle that includes an additional safety lever

(Fig. 13). This additional lever must be fully depressed

throughout the contact actuation sequence for the tool

to drive any fasteners. If the auxiliary handle lever is

not depressed, the tool will not cycle.

SEQUENTIAL ACTUATION

The sequential actuation requires the operator to

hold the tool against the work with the safety yoke

depressed before pulling the trigger. In order to drive

additional fasteners, the trigger must be released and

the tool lifted away from the work, before repeating the

above mentioned steps.

This makes accurate fastener placement easier,

for instance on framing, toe nailing and crating

applications. The sequential actuation allows exact

fastener location without the possibility of driving

a second fastener on recoil, as described under

Contact Trip (below). The sequential actuation tool

has a positive safety advantage because it will not

accidentally drive a fastener if the tool is contacted

against the work - or anything else - while the operator

is holding the trigger pulled.

m This tool is intended to be used for fastening wood

to wood in pallet/crate (-1-E / -2-E) and construction

applications (-2-E). DO NOT USE for fastening harder

materials which could cause buckling of the fasteners

and damage to the tool. If you are unsure of the suitability

of this tool for certain applications, please contact your

local sales oce.

LOADING THE TOOL

m Warning! When loading the tool 1) Never place

ahand or any part of the body in fastener discharge

area of the tool; 2) Never point the tool at self or

anyone else; 3) Do not pull the trigger or depress

the safety yoke as accidental actuation may occur,

possibly causing injury.

Note: Use only fasteners recommended by Bostitch

for use in Bostitch tools or nails which meet Bostitch

specifications.

MAGAZINE INSERT (IC50-2-E & IC50-1-E ONLY)

This tool comes with a metal insert for the magazine

foruse with flat coils of nails. To install the insert:

1. Disconnect the tool from the air supply.

2. Open the magazine: Pull down on the latch and

swing the door open (Fig. 1).

Swing magazine cover open. (Fig. 2).

3. Slide one side of the insert plate over the edge of

the magazine cover (Fig. 3) ensuring that the catch is

correctly positioned (Fig. 4).

4. Slide the other side of the insert plate into position so

that the insert is fitted securely in place (Fig. 5).

LOADING (ALL MODELS)

1. Disconnect the tool from the air supply.

2. Open the magazine: Pull down on the latch and

swing the door open. Swing magazine cover open.

(Fig. 6)

3. Check adjustment: the nailer must be set for the

length of nail to be used. Nails will not feed smoothly

if the magazine is not correctly adjusted. To adjust

the magazine, refer to ‘Adjusting the Magazine’

shown below.

4. Load the coil of nails: Place the coil of nails over the

post in the magazine. Uncoil enough nails to reach

the feed pawl. Place the first nail in front of the front

tooth on the feed pawl, in the driver channel. The nail

heads must be in the slot in the nose. (Fig. 7)

5. Swing the door/magazine cover closed. Check that

the latch engages when released. (If it does not

engage, check that the nail heads are in the slot in

the nose.)

m Warning!

•

IMPORTANT SAFETY INFORMATION ENCLOSED.

•

READ THIS MANUAL BEFORE OPERATING THE TOOL.

•

SAVE FOR FUTURE REFERENCE.

•

FAILURE TO OBSERVE THE FOLLOWING

WARNINGS COULD RESULT IN INJURY.

•

Do not use damaged, frayed or

deteriorated air hoses and fittings.

•

Air powered tools can vibrate in use.

Vibration, repetitive motions or

uncomfortable positions may be harmful

to your hands and arms. Stop using any

machine if discomfort, tingling feeling

or pain occurs. Seek nedical advice

before resuming use.

•

Do not carry the tool by the hose.

•

Keep body stance balanced and firm.

Do not overreach when operating this tool.

•

Always turn o the air supply and

disconnect the air supply hose before

installing, removing or adjusting any

accessory on this tool, or before

parforming any maintenance on this tool.

•

Use protective equipment such as

glasses, gloves, safety shoes as well

as acoustic protection. Remain vigilant,

use common sense and pay attention

when using the machine.

•

Always wear suitable CE marked

eye protection when operating or

performing maintenance on this tool.

MAX

PSI

•

Operate at no more than the tool’s

maximum pressure stated in column

“I” of the technical data table.

•

Do not over-oil and do not use heavy

grade oil as stalling and low

performance may result.

Loading...

Loading...