SAFETY PRECAUTIONS

TRENCHERS

BB

MAINTAINING THE TRENCHER

1.

Replace all safety shields and guards when performing maintenance.

Do not operate the trencher with protective equipment removed.

2. Lower the trenching boom, and shut off the engine before working on

the unit. Never perform maintenance on a trencher while it is run-

ning.

3.

Make sure all operating and residual pressures are relieved before

working on a hydraulic system. Shut engine off, and operate all the

controls to relieve any pressure.

4. Use only manufacturer recommended replacement parts. Other parts

may be substandard in fit and quality.

5.

Do not set any relief valve higher than recommended by the manufac-

turer. Relief valves should be checked and adjusted only by a trained

service technician. Do not remove or block a relief valve.

6. Observe proper maintenance schedules. Proper maintenance can help

prevent a hazardous condition.

7.

Always wear safety goggles or glasses when working on equipment.

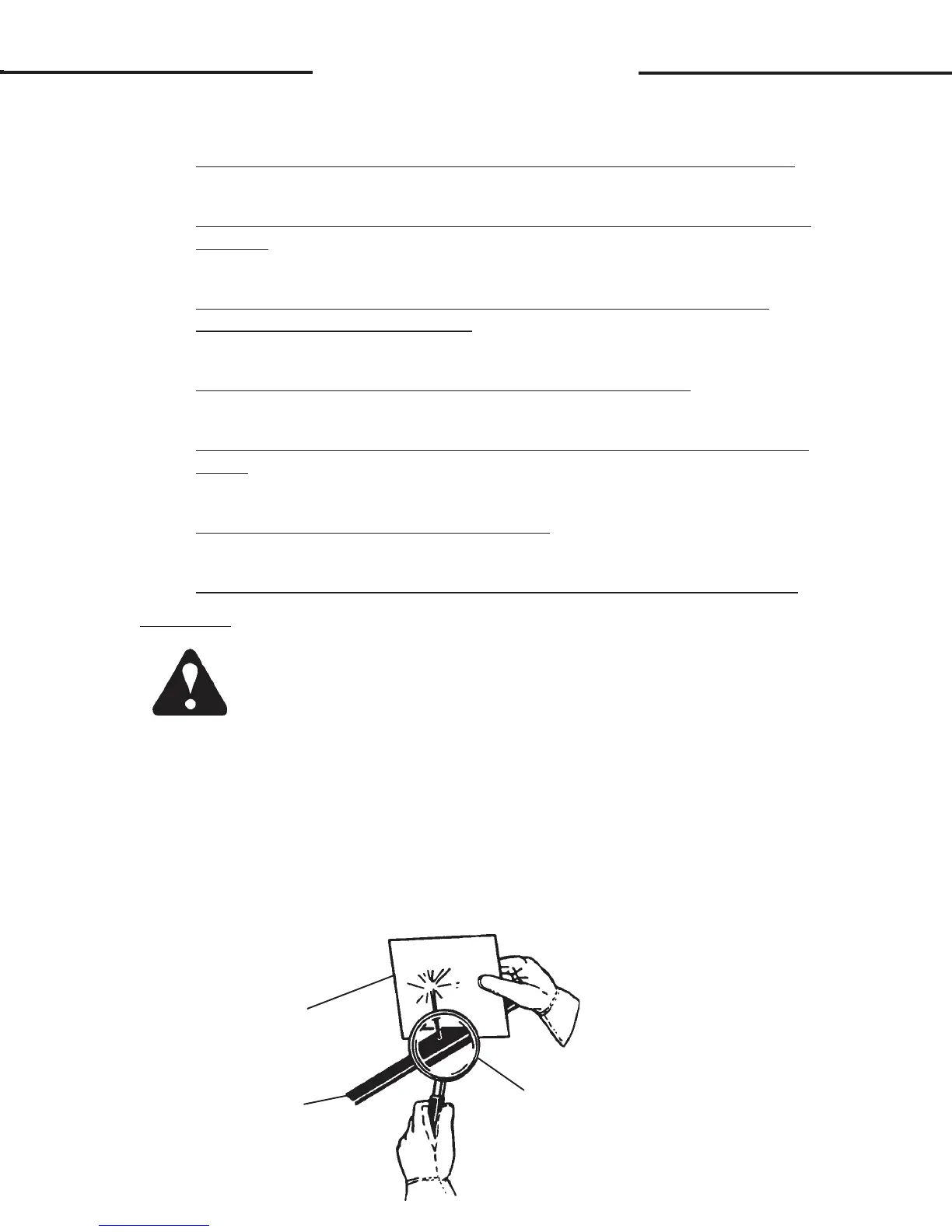

WARNING! Escaping fluid under pressure can have sufficient force to pen-

etrate the skin, causing serious personal injury. Fluid escaping

from a very small hole can be almost invisible. Use a piece of

cardboard or wood, rather than hands to search for suspected

leaks.

Keep unprotected body parts, such as face, eyes, and arms as

far away as possible from a suspected leak. Flesh injected

with hydraulic fluid may develop gangrene or other permanent

disabilities.

If injured by injected fluid, see a doctor at once. If your doctor

is not familiar with this type of injury, ask him to research it

immediately to determine proper treatment.

CARDBOARD

HYDRAULIC HOSE

OR FITTING

MAGNIFYING GLASS

4216

2-26-92-2

Loading...

Loading...