50

7

7

Check Connecting Rod Bearing Clearances

NOTE: If connecting rod bearings show signs of

flaking or scoring, bearings must be replaced.

NOTE: Connecting rod bearings and crankpin

journals must be clean and free of oil.

1. With upper bearing assembled to the

connecting rod, install the connecting rod.

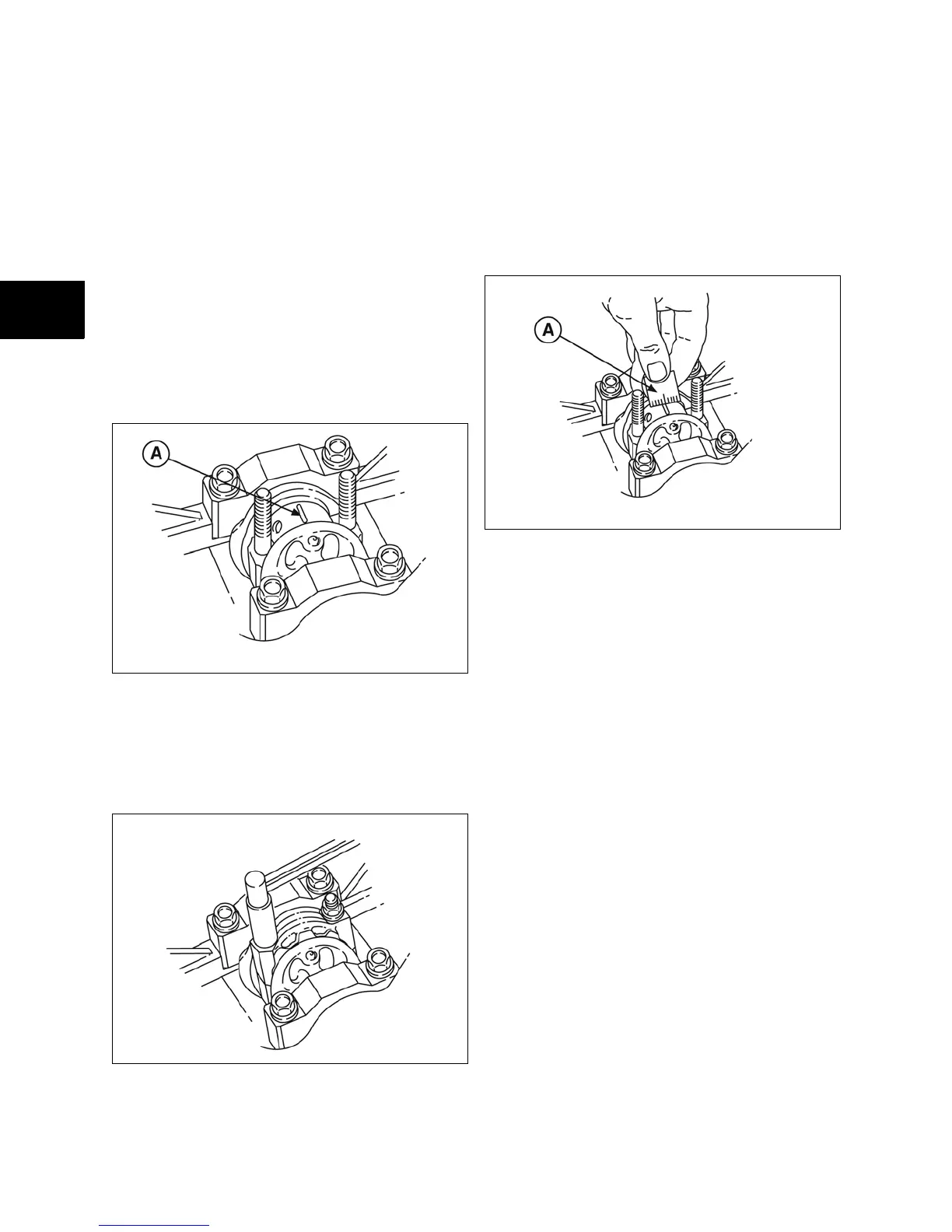

2. Lay a strip of plastigage lengthwise on journal

(A, Figure 7).

NOTE: Do not lay plastigage across hole in

crankshaft journal.

Figure 7

3. Assemble connecting rod cap with bearing

and torque to values listed in Section 14

(Figure 8).

NOTE: Do not allow crankshaft to rotate.

Figure 8

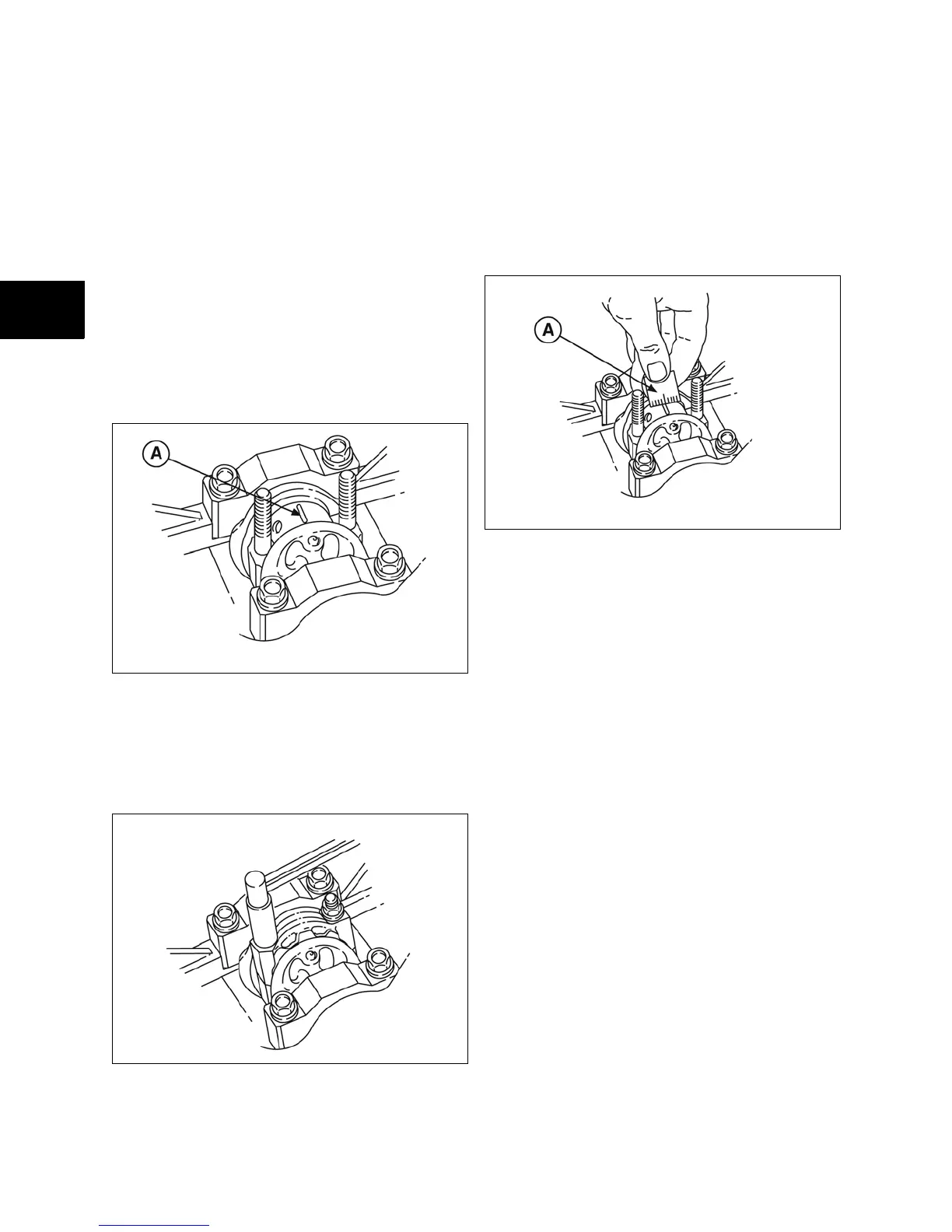

4. Remove the connecting rod cap. Measure the

plastigage at its widest point (A, Figure 9). If

the clearance is not within specification,

replace the bearings.

• Standard Main Bearing Clearance -

0.0008 - 0.0017 in. (0.020 - 0.044 mm)

• Reject Main Bearing Clearance - 0.0028

in. (0.07 mm)

Figure 9

5. Repeat procedure for each main bearing.

Check Crankshaft End Play

1. With thrust washers installed, check

crankshaft end play at #3 main bearing

(Figure 10).

• Standard Crankshaft End Play - 0.0008 -

0.009 in. (0.020 - 0.23 mm)

• Limit Crankshaft End Play - 0.012 in. (0.30

mm)

2. If end play exceeds limit,0.005 in. (0.13 mm),

over size thrust washers are available. See

illustrated parts list for part numbers.

Loading...

Loading...