6

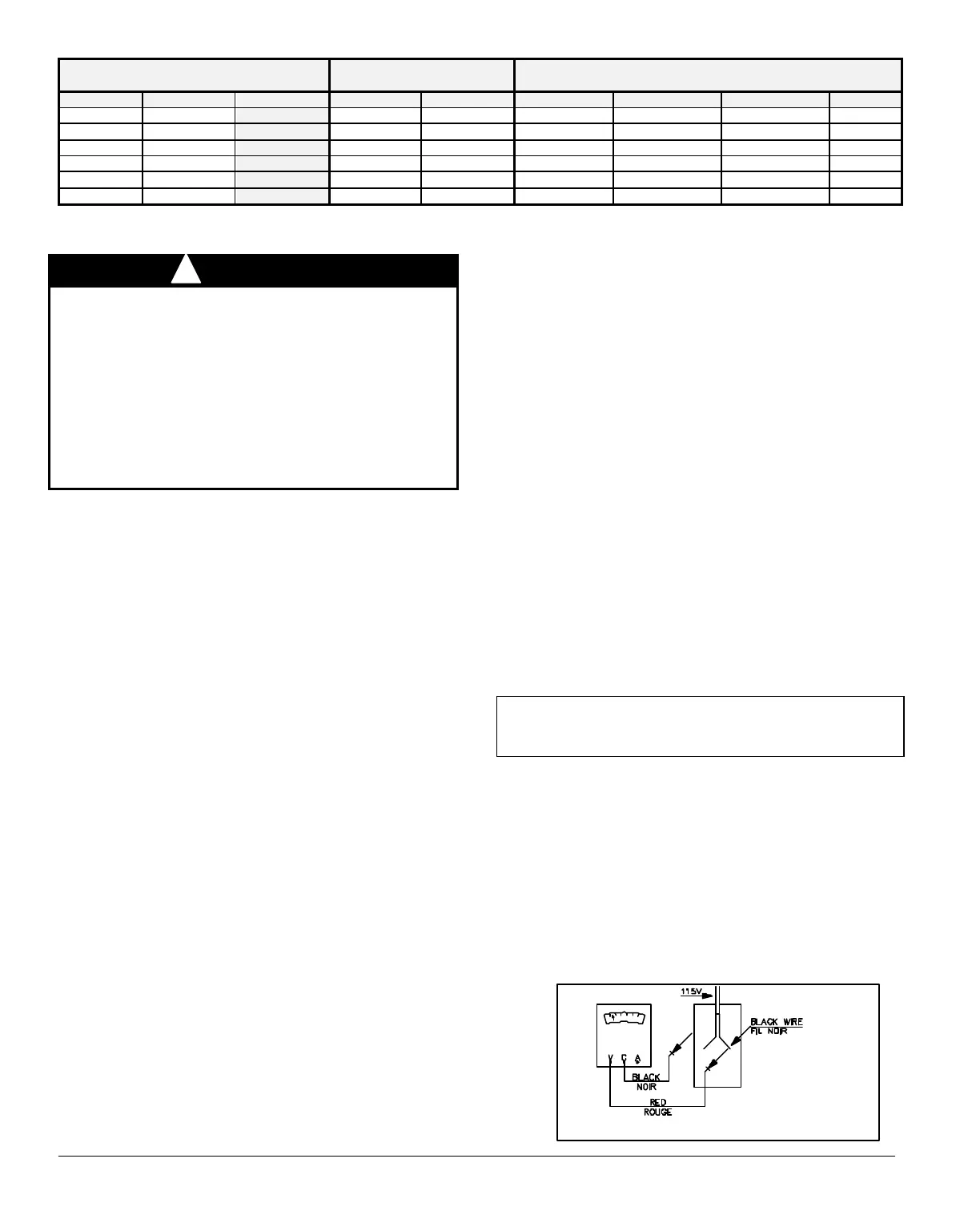

TABLE 2

Total input rating of all

connected appliances

Flue inside diameter (in) Minimum base temperature (ºF)

for chimney height (ft) of :

kW kBtu/h USGPH Min. Max. 11 20 28 36

21 70 0.50 3 5 300 400 535 725

27 91 0.65 3 5 275 340 430 535

31 105 0.75 4 5 260 320 380 475

36 119 0.85 4 5 250 300 355 430

41 140 1.00 4 6 225 300 365 430

51 175 1.25 4 6 240 275 320 365

1.5) AIR FOR COMBUSTION

WARNING

Poisonous carbon monoxide gas hazard.

Comply with ANSI/NFPA (U.S.) or CSA (Canada)

standards for the installation of Oil Burning

Equipment and applicable provisions of local

building codes to provide combustion and

ventilation air.

Failure to provide adequate combustion and

ventilation air can result in personal injury and/or

death.

1.5.1) General

Oil furnaces must have an adequate supply of combustion air. It is

common practice to assume that older homes have sufficient

infiltration to accommodate the combustion air requirement for the

furnace. However, home improvements such as new windows, doors,

and weather stripping have dramatically reduced the volume of air

leakage into a home.

Home air exhausters are common. Bathroom and kitchen fans, power

vented clothes dryers, and water heaters all tend to create negativ e

pressure in the home. Should this occur, the chimney becomes less

and less effective and can easily downdraft.

Heat recovery ventilation (HRV) systems are gaining in popularity.

HRVs are not designed to supply combustion air. If not properly

balanced, a serious negative pressure condition could develop in the

dwelling.

1.5.2) Contaminated Combustion Air

Installation in certain areas or types of structures will increase the

exposure to chemicals or halogens which may harm the furnace.

These cases will require that only outside air be used for combustion.

The following areas or types of structures may contain or have

exposure to the substances listed below. The installation must be

evaluated carefully as it may be necessary to provide outside air for

combustion.

a. Commercial buildings;

b. Buildings with indoor pools;

c. Furnaces installed near chemical storage areas.

Exposure to these substances:

a. Permanent wave solutions for hair;

b. Chlorinated waxes and cleaners;

c. Chlorine based swimming pool chemicals;

d. Water softening chemicals;

e. De-icing salts or chemicals;

f. Carbon tetrachloride ;

g. Halogen type refrigerants ;

h. Cleaning solvents (such as perchloroethylene);

i. Printing inks, paint removers, varnishes, etc..;

j. Hydrochloric acid;

k. Solvent cements and glues;

l. Antistatic fabric softeners for clothes dryers;

m. Acid based masonry cleaning materials.

1.6) OIL TANKS AND LINES

Check your local codes for the installation of the tank and accessories.

A manual shut-off valve and an oil filter shall follow in sequence from

tank to burner. Be sure that the oil line is clean before connecting to

the burner. The oil line should be protected to eliminate any possible

damage. Installations having the fuel oil tank below the burner level

must employ a two pipe fuel supply system with an appropriate fuel

pump (more than an 8 foot rise uses a 2 stage pump and more than a

16 foot rise an auxiliary pump).

At the beginning of each heating season or each year, check the

complete oil distribution system for leaks.

Follow the pump instructions to determine the size of tubing you need

in relation to the rise, or the horizontal distance.

1.7) BURNER INSTALLATION

Mount burner on the 3 bolts fixed to the mounting plate. Use the

gasket supplied between burner mounting support and burner. Install

washer and nuts. The air tube must be centred in the opening of the

combustion chamber.

CAUTION

Do not turn on the burner until you have checked the

polarity

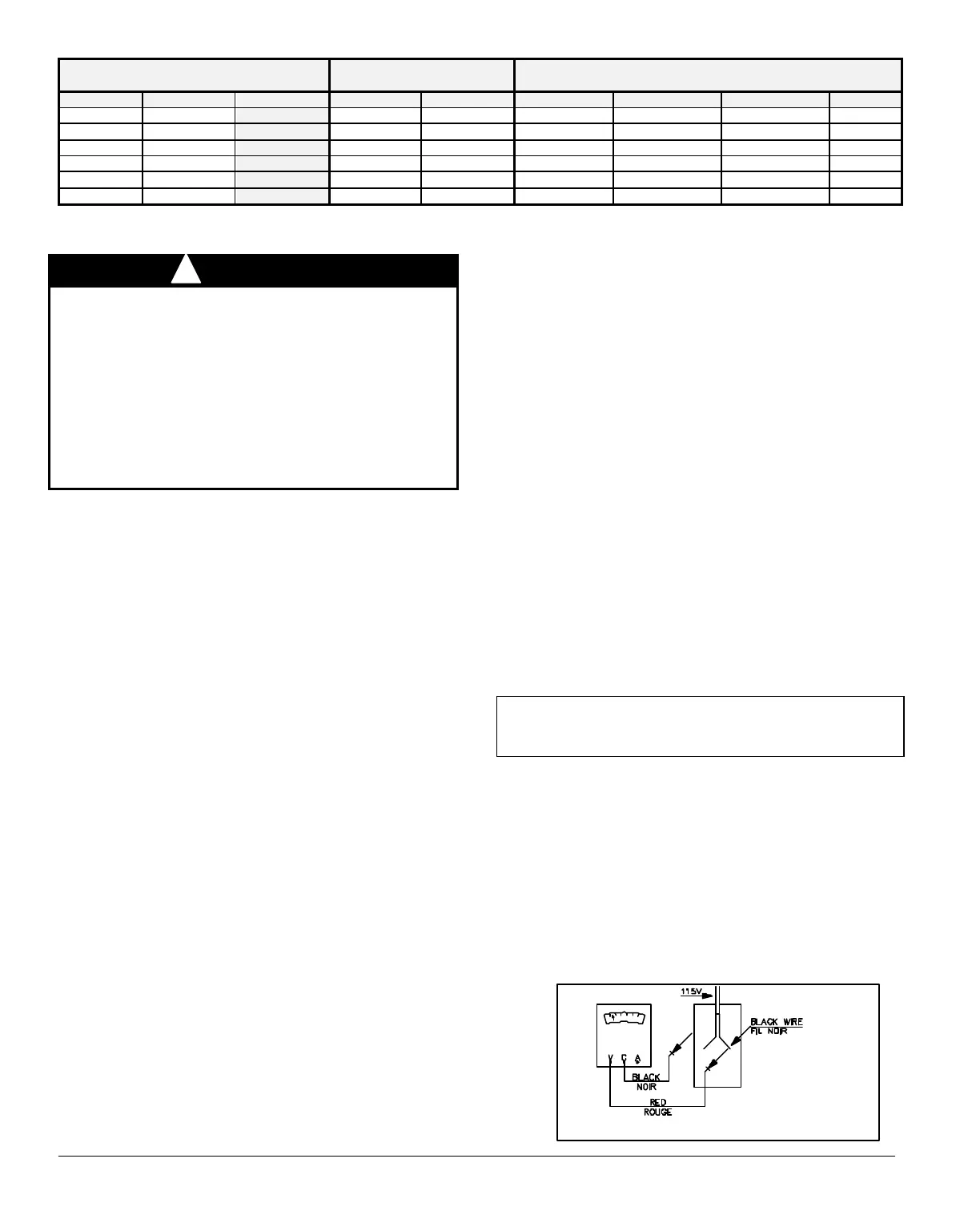

Checking the polarity

Oil burners used on furnaces have solid state control systems which

make them sensitive to the proper connections of the hot and neutral

power lines. The controls will be damaged if the two lines are

reversed. Refer to Figure 1.

1. Set your voltmeter to line voltage;

2. Place one prong on your grounded electric entry box and one

prong on the black wire;

3. Read the voltage;

4. If the voltage is zero, check the white wire. If line voltage shows,

reverse the 115-volt leads entering the furnace junction box.

FIGURE 1

DNS-0864 Rev. A

Loading...

Loading...