10

PART 3

MAINTENANCE

3.1) GENERAL

Preventive Maintenance

Preventive maintenance is the best way to avoid unnecessary

expense and inconvenience. Have your heating system and

burner inspected at regular intervals by a qualified service man.

After inspection, a complete combustion test must be performed after

each annual service of the unit to maintain optimum performance and

reliability.

WARNING

Electrical shock hazard.

Turn OFF power to furnace before any disassembly

or servicing.

Failure to do so can result in property damage,

bodily injury and/or death.

Do not alter the unit or its controls. Call a qualified service

technician.

Before calling for service, check the following:

a. Check oil tank gauge and check if the oil tank valve is open;

b. Check fuse or circuit breaker;

c. Check if shut-off switch is “ON”;

d. Reset thermostat above room temperature;

e. If ignition does not occur turn off the disconnect switch and call a

qualified service technician.

When ordering replacement parts, specify the complete furnace

model number and serial number.

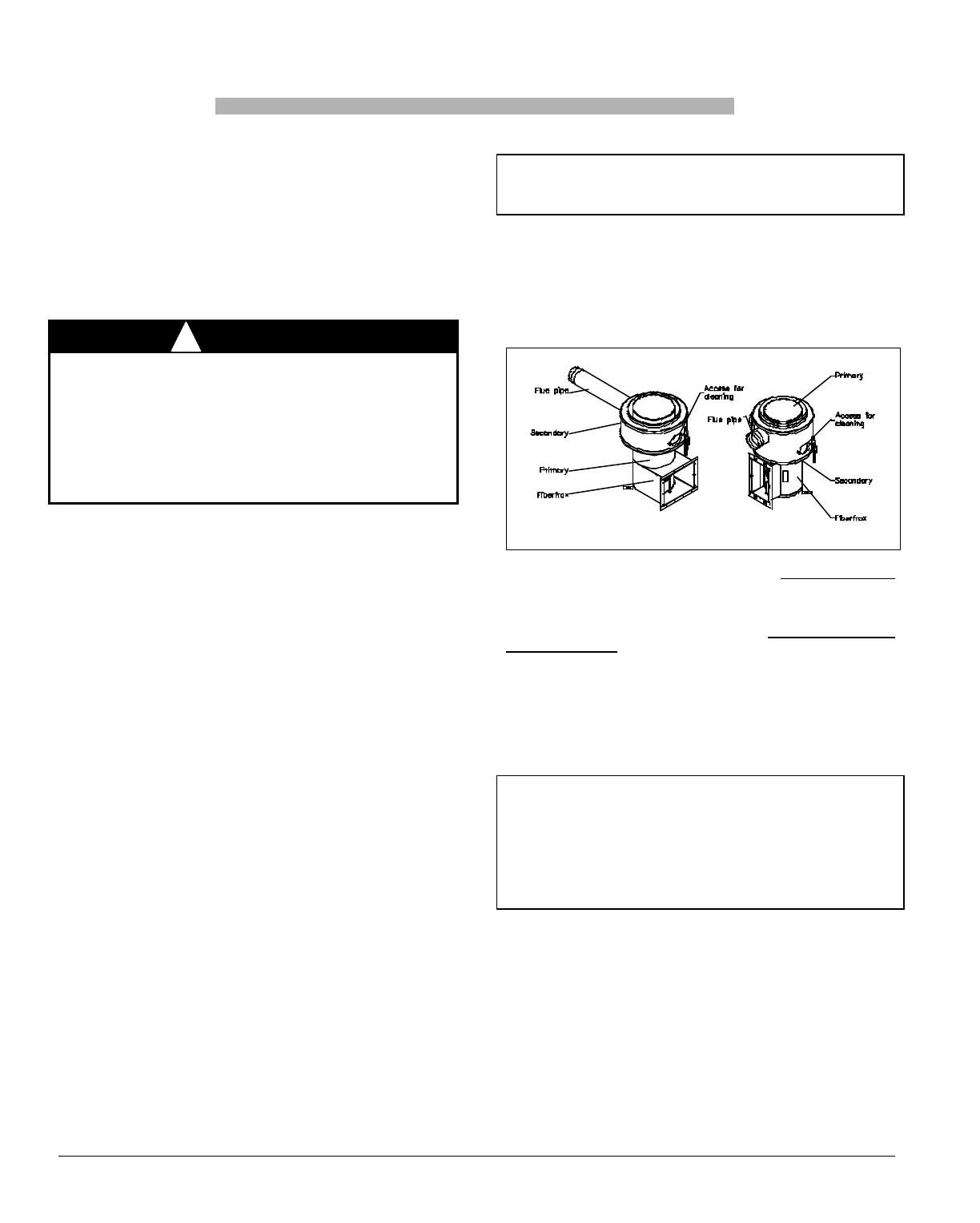

3.1.1) Heat exchanger

The entire heat exchanger should be inspected annually for soot

accumulation. If the burner is operating normally, there should very

little accumulation. If the heat exchanger requires scale removal, use a

wire brush first to loosen the scale and then vacuum the soot and

scale that has fallen into the secondary heat exchanger (radiator)

section. You will find that a 36 inch long flexible hose attachment will

be helpful to reach into the back of the radiator; a piece of 1/2” flexible

gas connector, or a piece of 1/2” liquid-tight vinyl jacket metallic

electrical conduit works well as a makeshift device.

Cleaning the heat exchanger

Remove the 3-bolt flange from the front of the furnace to expose the

clean-out port and check for soot deposits. If there is very little soot in

the secondary section visible from the clean-out port (see Figure 2),

you will not need to clean it. However, if you notice scaling, you should

remove the scale.

The wrap-around radiator can now be cleaned entirely from the front

inspection port. Also, the new furnace has external clean-out ports so

the soot does not fall into the fan compartment during the cleaning

operation.

IMPORTANT

Do not vacuum the ceramic chamber—it is easily

damage.

Soot will have collected in the first sections of the heat exchangers

only if the burner was started after the combustion chamber was

flooded with oil, or if the burner has been operating in a severely

fouled condition.

FIGURE 2

The use of a brush, vacuum cleaner or scraper is not recommended

for cleaning the primary. The primary has a fiberfrax liner and will be

damaged.

If you have to clean the interior of the primary, do not strike or scratch

the fiberfrax surf ace. Debris must be removed by hand. If the fiberfrax

lining is damaged in any way, such as through basement flooding, the

chamber must be replaced before the furnace is fired.

3.1.2) Refractory fire pot

Remove the burner and check the firepot.

IMPORTANT

Use extreme care if cleaning of the pot is required. After

firing, the pot becomes very fragile. Do not use any

commercially available soot remover. This furnace has

a fibre type refractory combustion chamber. Normal

servicing of this unit does not require cleaning of the

combustion chamber.

If the pot is damaged, it must be replaced. A damaged pot could lead

to premature heat exchanger failure. Cracking of the fire pot is normal,

however, replace the pot only if the cracks have propagated more

than 2/3 the way through the wall thickness. The average wall

thickness of the firepot is ½”.

Flooding of the fire pot

Flooding can occur when the oil primary control has been reset a

number of times in a no-heat situation. Each time oil is fired into the

pot and does not ignite, it is absorbed into the pot. Even if the burner is

removed and the pot is felt for wetness, it is difficult to assess the

degree of oil absorption by the pot.

DNS-0486 Rev. B

MBP1-A, MBP2-

MBP-U

Model MBPF-A

Loading...

Loading...