44

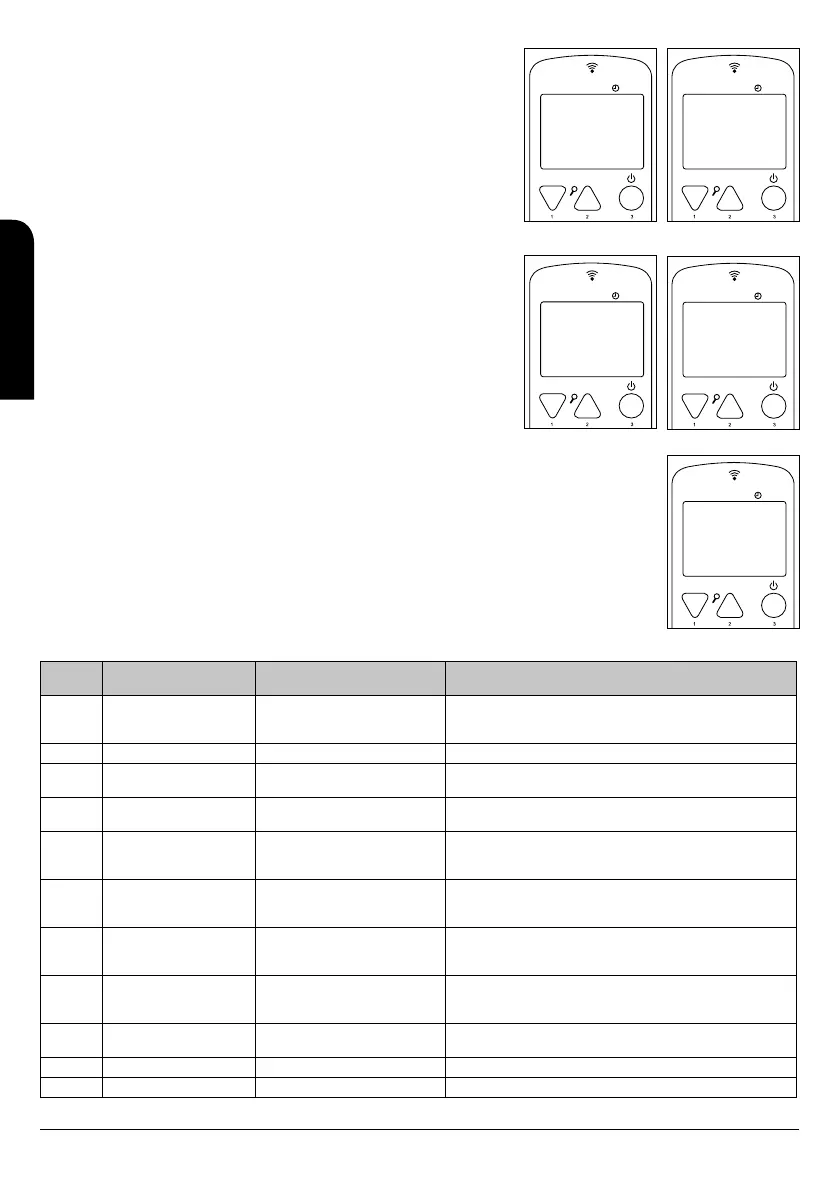

11.7 THERMAL ALARM

MENU

D104

MENU

D105

ALARM 7

SECURITY

THERMAL

ALARM 8

FAILURE

PRESSURE

If in working phase the thermal security alarm is shows up (see drawing D104), the turn-

off stage will be immediately activated. This alarm means an overheating of the internal

part of the tank, this device blocks the operation of the machine. The restart needs to

be done manually by an authorised technician.

The restoration of the 90ºC safety device is not included in the warranty unless the

technical assistance centre demonstrates a faulty component.

11.8 COMBUSTION CHAMBER PRESSURE ALARM

It happens when there is a pressure change in the combustion chamber (door open, dirt

registers, air returns...). The electronic pressure switch blocks the working of the stove

or insert and shows the alarm. After that the turn-off stage will be immediately activated

(see drawing D105).

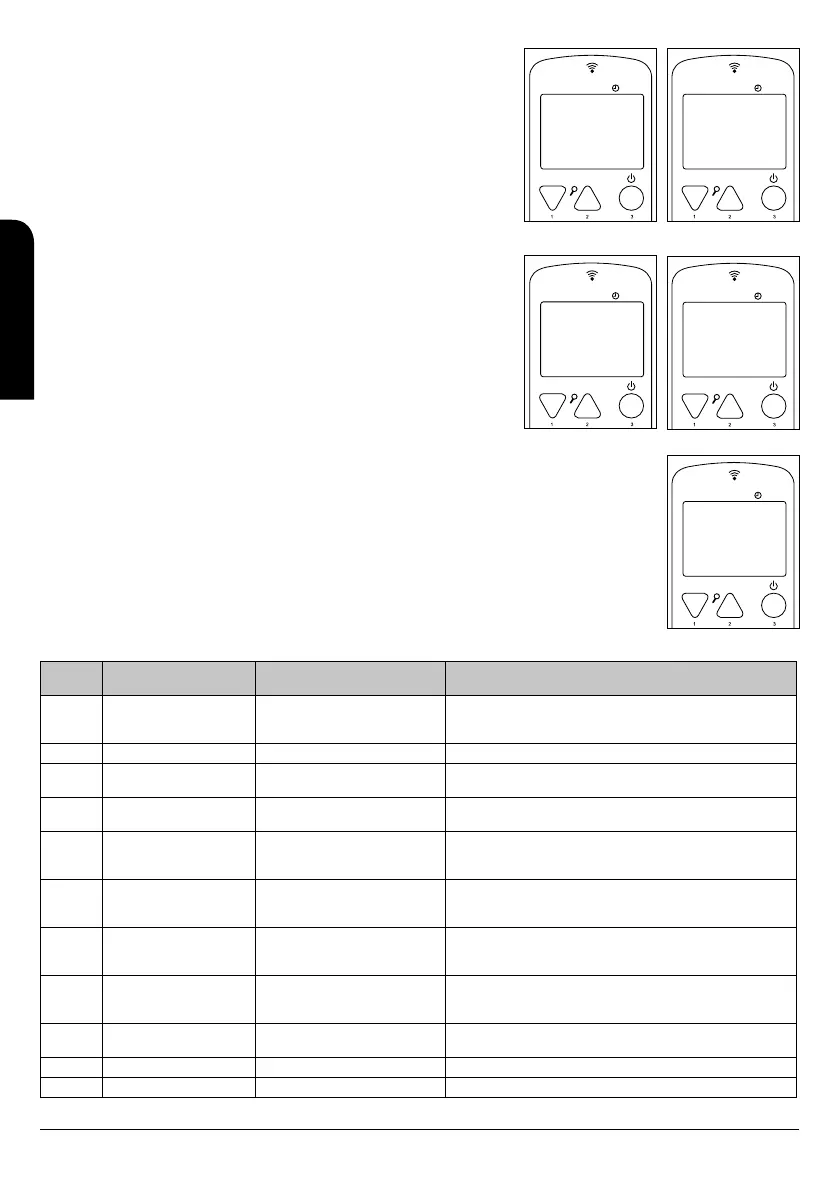

MENU

D106

MENU

D107

ALARM 9

FLOW

ALARM

ALARM b

ENDLESS

ERROR

11.9 LACK OF PRIMARY AIR INTAKE FLOW ALARM

Your stove or insert has a flow sensor placed inside the primary air suction pipe. It

detects the proper circulation of combustion air and the smoke exhaust. In case of

insufficient air inlet (due to incorrect smoke outlet or improper air intake), the sensor

sends a “block” signal. After that the turn-off stage will be immediately activated (see

drawing D106).

11.10 WORM GEAR FAILURE ALARM

MENU

D108

ALARM

FAILURE

FLOWMETER

The control of the fuel amount to the stove or insert is automatically made through

the electronic programming. It goes off in the event of the endless breakdown. If this

happens, the stove or insert stops and the display will show up the following alarm.

Right after, the turn-off stage will be immediately activated (see drawing D107).

If this alarm appears you must contact the technical support service.

11.11 FLOW SENSOR ANOMALY SENSOR

In case of anomaly of the flow sensor, placed on the primary air aspiration tube, a blockage signal is send to the

stove or insert and right after the turn-off stage will be immediately activated. (see drawing D108).

If this alarm appears you must contact the technical support service.

11.12 ALARM LIST, PROBLEM AND POSSIBLE SOLUTIONS

ALARM

CODE

DESCRIPTION PROBLEM POSSIBLE SOLUTION

AL1 BLACK OUT

The stove or insert has been

temporarily without electric

current.

Press button 3 for a few seconds and let the final cleaning

stage to finish. The boiler will come back to the turn-off status.

AL 2 SMOKE PROBE Problem with the smoke probe. Check the probe connection or replace it.

AL 3 TEMP. SMOKE

The smoke temperature is higher

than 270ºC.

Regulate the pellet drop and/or the extractor speed. Verify the

type of fuel that has been used.

AL 4

BREAKDOWN

EXTRACTOR

Problem with the smoke

extractor.

Check the extractor electrical connection or replace it.

AL 5 START-UP FAILURE The fuel does not fall or burn.

Check the geared motor and the resistor way of working.

Check a possible blockage of the endless. Verify that there is

fuel in the tank.

AL 6 NO PELLET

There is no fuel in the hopper or

it does not fall inside the burner.

Refill tank. Check the endless working. Check the fuel

characteristics and that it has not become compacted. Clean

the bottom of the hopper.

AL 7 THERMAL ALARM

The fuel thermal security

thermostat has shot up.

Restart the thermostat manually. Check the reason why the

temperature is excessive and provoked the overheating (fuel

drop, draw excess, fuel type...)

AL 8 DEPRESSION

The combustion chamber is on

depression.

Verify that the chamber is hermetic : check locks, gaskets…

etc. Check that the gas installation is correct (excess of

horizontal sections, elbow joint, etc). Possible fuel blockage.

AL 9 LACK OF FLOW

Lack of primary air or installation

not appropriate.

Check the primary air inlet. Verify installation (excess of

horizontal section, curves, dirtiness, etc).

AL FLOWMETER FAILURE The flow sensor is broken. Replace the flow sensor.

AL b ENDLESS ERROR The endless spins continuously. Verify the electrical connection of the endless.

INSTALLATION, OPERATING AND SERVICING INSTRUCTIONS RADIOFREQUENCY SERIES

EN

Loading...

Loading...