OKOK

MENUMENU

18

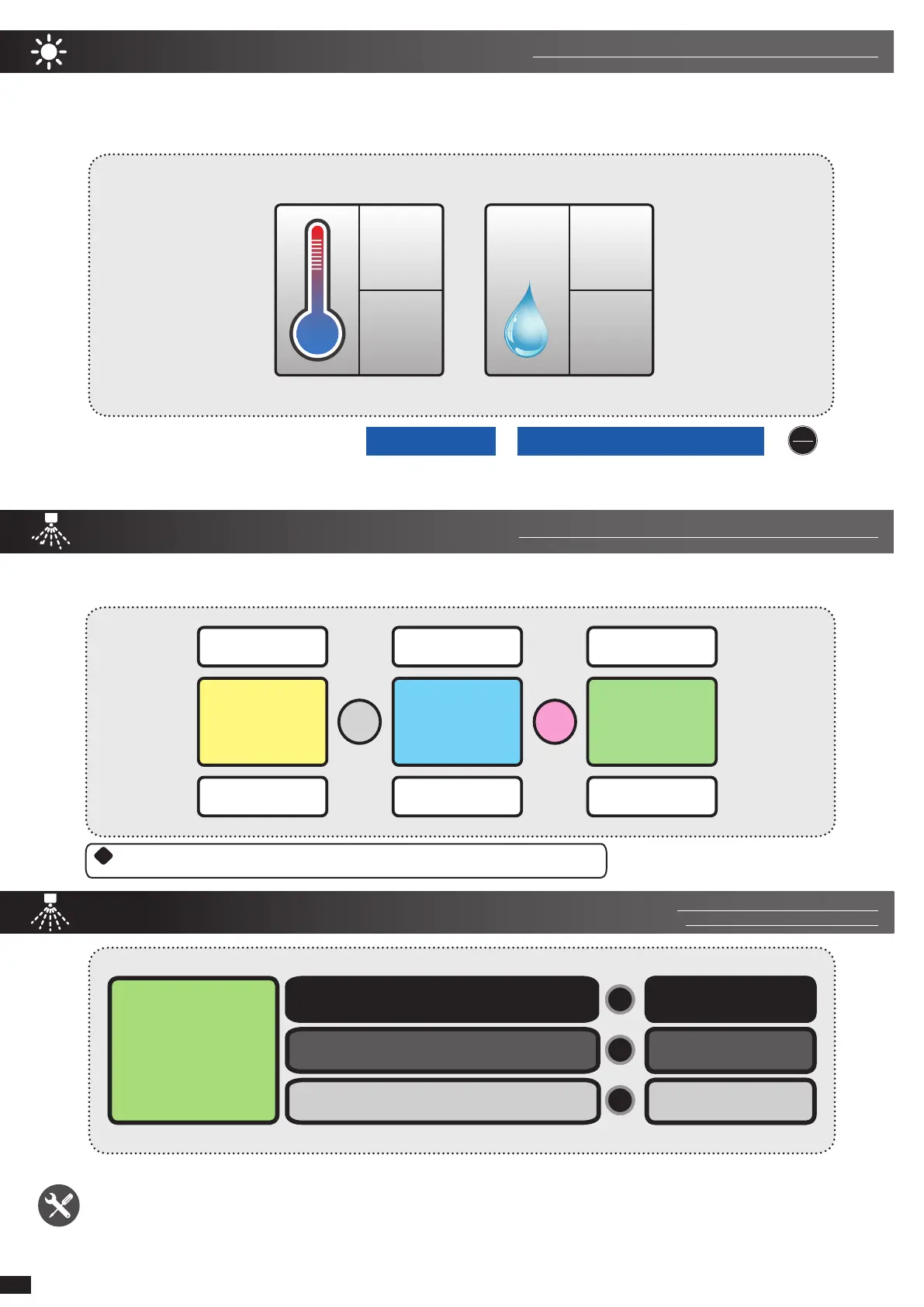

MIN

TEMPERATURE

30

MAX

C

°

°

HUMIDITY

35

MIN

85

MAX

%

Min Firmware v2.5

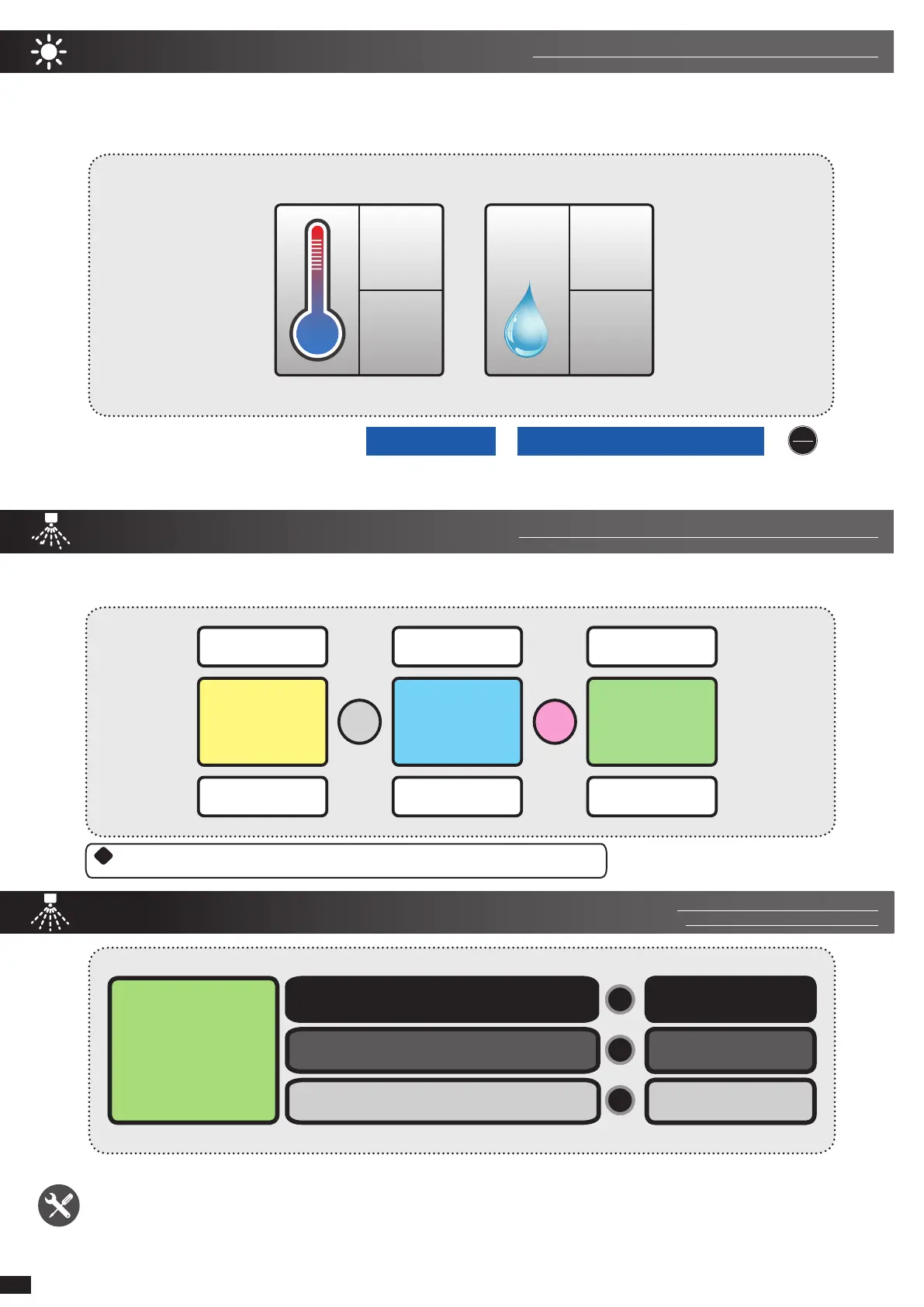

1 Litre

1.25 Kg

Pre-Treatment

Solution

2 Litres

2 Kg

Distilled

Water

3 Litres

3.25 Kg

Pre-Treatment

Ready to Use

+ =

Pre-Treatment

Ready to Use

=

40-50 Grams

30-39 Grams

15-29 Grams

High Absorbency

Thick materials or open

weaves like hoodies

Med. Absorbency

Regular Cotton Tees

113-170gs

Quantity

Low Absorbency

Thin Material + Blend

or Specialty Items

=

==

==

!

The printer can

operate outside

of these ranges

however it may

use more ink

or take longer

to print.

Mandatory Temperature & Humidity Requirements:

ENVIRONMENTAL CONDITIONS

Help keep your printer in warranty while saving on ink, consumables, and time

You can use an empty distilled water jug and marker to measure out the amount of Pre-Treatment by drawing a

line on the jug - then fill to that line twice with distilled water, adding the contents into the Ready to Use container.

To check Go to the menu:

Maintenance > Temperature/Humidity info >

PRE-TREATMENT RATIO

PRE-TREATMENT QUANTITY on T-SHIRTS

T

he correct Pre-treat volume for a garment should be determined by a garment's absorbency rate in conjunction with

using the highlight check pattern to help determine driver ink settings.

Don’t forget that you have to define a surface of 35 x 40 cm (14 x 16 inches) with your Pre-Treatment machine and

weigh with a scale after applying the Pre-Treatment liquid on a T-shirt.

If the temperature is too cold, the printer will automatically switch to Low-Temp Mode and reduce the speed!

Damages resulting from being too far outside of the environmental requirements may not be covered by warranty

Link to Understanding Environmental Conditions Document

Watch the Video: Learning to Prole a Garment for Pre-treating

Watch the Video for Understanding

the Highlight-Mask Check Pattern

2

If the Temperature and Humidity is not enough, then add an Evaporative Humidier

This mixing ratio might vary due to the type of garment which is used.

Loading...

Loading...