220

GEARCASE

SHIMMING AND GEAR BACKLASH CHECKS

SHIMMING AND GEAR

BACKLASH CHECKS

If the gearcase has been rebuilt or any internal

components have been replaced, the gears must

be properly shimmed and adjusted to ensure

smooth, reliable operation of the gears.

Checking the Forward Gear-to-

Pinion Gear Backlash

Install the driveshaft and bearing housing assem-

bly without Gasket Sealing Compound.

Install and tighten the pinion nut without Nut Lock

to a torque of 13 ft. lbs. (18 N·m).

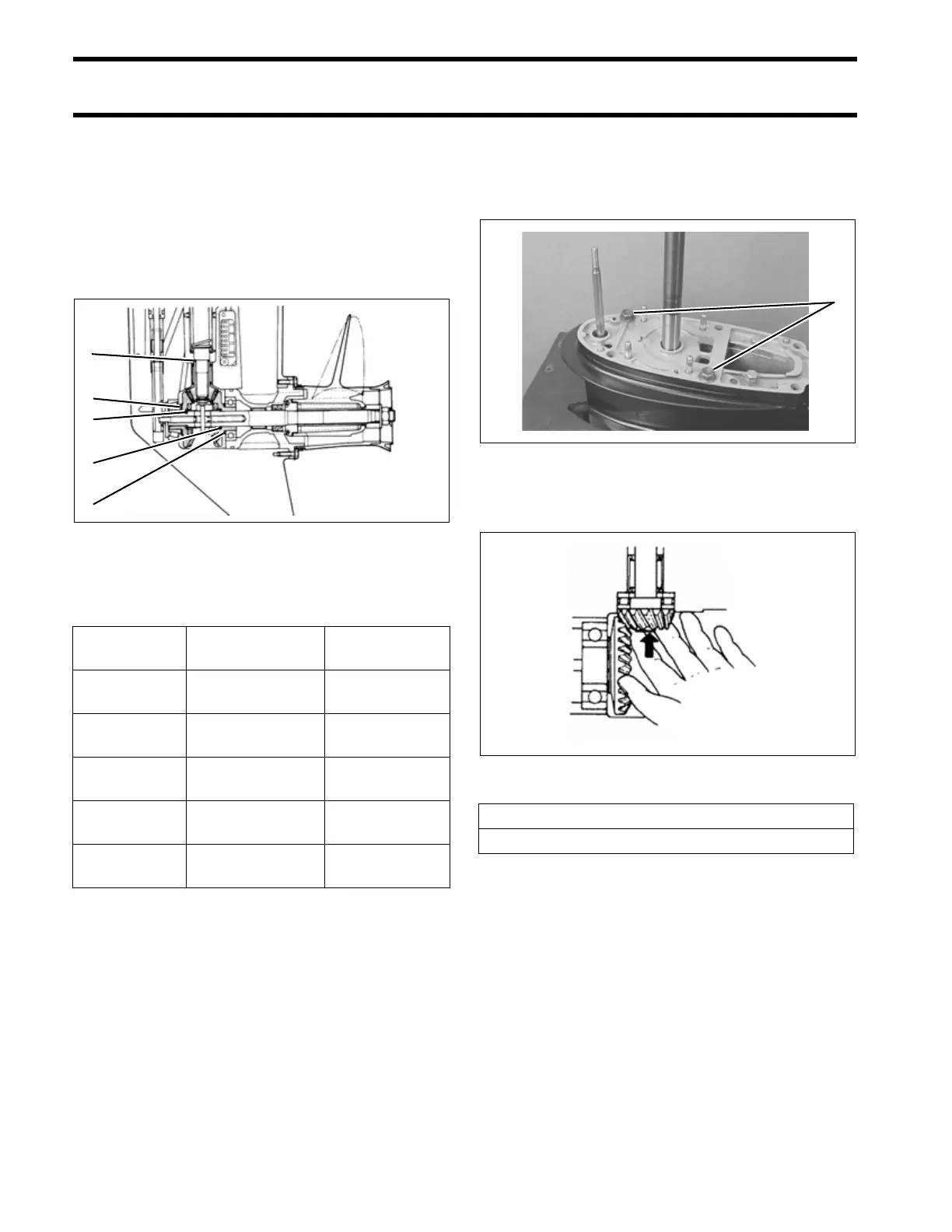

Temporarily fasten the driveshaft bearing housing

to the gearcase using two (2) bolts and nuts

placed through the two diagonally opposite gear-

case mounting holes.

Hold the pinion gear by hand, then gently rock the

forward gear back and forth by hand.

• If the backlash is greater than the specification,

the thickness of the forward gear shim must be

increased.

• If the backlash is less than the specification, the

thickness of the forward gear shim must be

decreased.

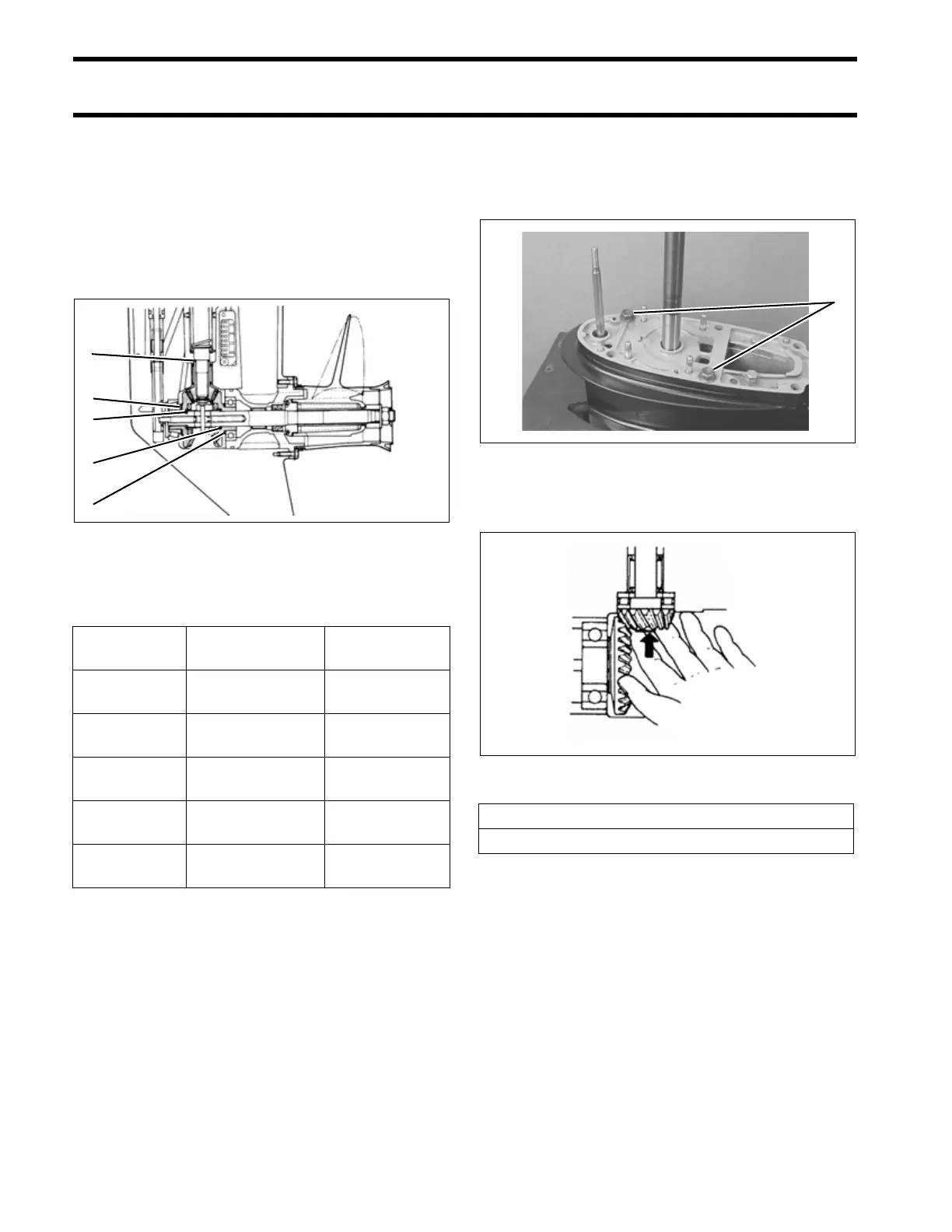

1. Pinion gear shim

2. Forward gear shim

3. Forward gear thrust washer

4. Reverse gear thrust washer

5. Reverse gear shim

001901

Item Available

thickness (mm)

Design spec

thickness (mm)

Pinion gear

shim

1.7, 1.8, 1.9, 2.0,

2.1, 2.2

2.0

Forward gear

shim

0.8, 0.9, 1.0, 1.1,

1.2, 1.3, 1.4, 1.5

1.2

Forward gear

thrust washer

2.0 2.0

Reverse gear

thrust washer

1.6, 1.8, 2.0, 2.2,

2.4, 2.6

2.0

Reverse gear

shim

0.2, 0.5, 0.8, 1.0 1.5

1

2

3

4

5

1. Bolts (2) 001888

001902

Forward Gear to Pinion Gear Backlash

0.004 – 0.008 in. (0.10 – 0.20 mm)

1

Loading...

Loading...