—10—

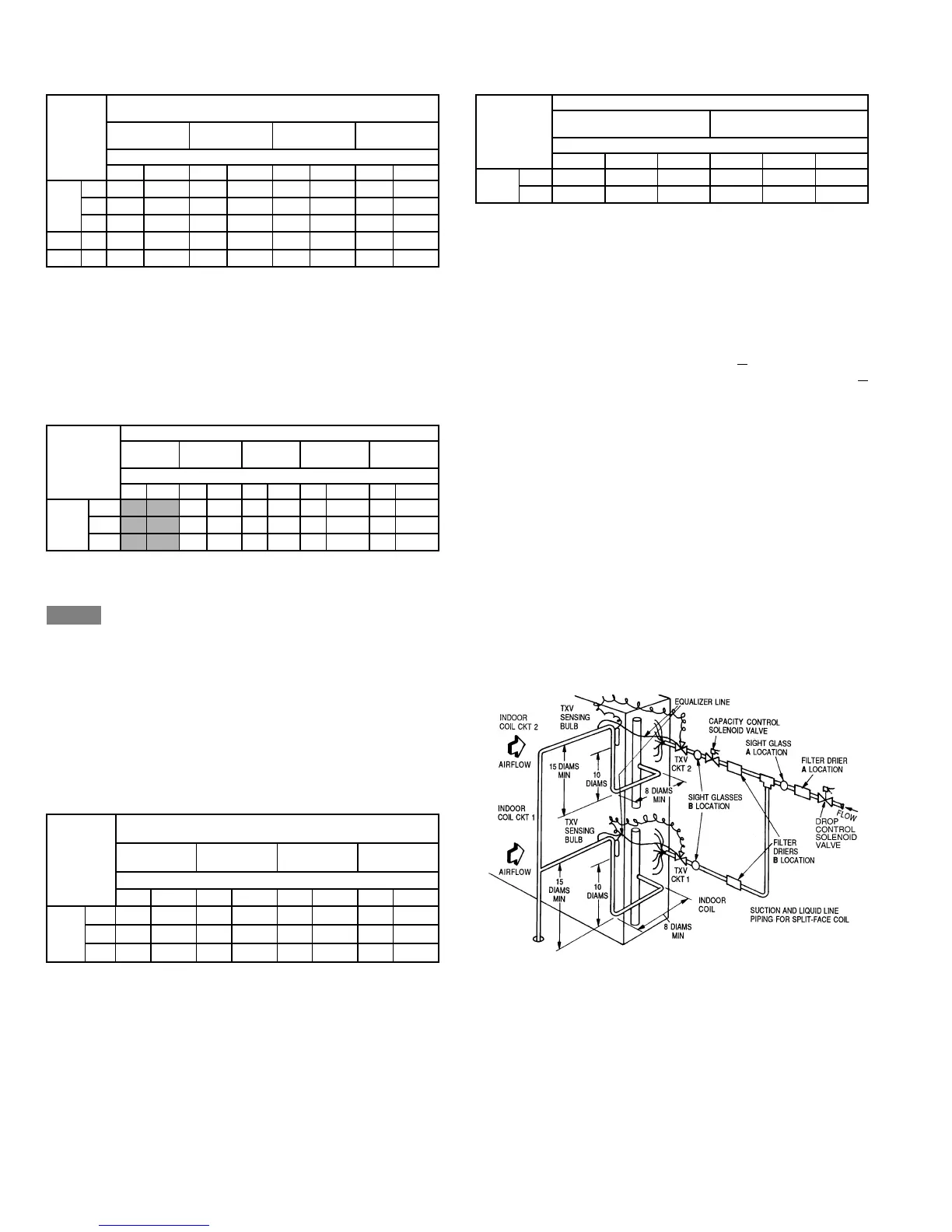

Table 3A — Refrigerant Piping Sizes —

569D, 576C, 569F Units

LEGEND

L—Liquid Line S—Suction Line

*Field-supplied suction accumulator required.

NOTES:

1. Pipe sizes are based on a 2 F (1 C) loss for liquid and suction lines.

2. Pipe sizes are based on the maximum linear length, shown for each

column, plus a 50% allowance for fittings.

3. Charge units with R-22 in accordance with unit installation instructions.

Table 3B — Refrigerant Piping Sizes —

566D Units

LEGEND

Close-coupled

*Field-supplied suction accumulator required.

†Requires a double suction riser if 2 unloaders are used and the evaporator is

below the condensing unit. See Table 4 and Fig. 6 for more information.

NOTES:

1. Pipe sizes are based on a 2 F (1.1 C) loss for liquid lines and a 1.5 F

(0.8 C) loss for suction lines.

2. Pipe sizes are based on an equivalent length equal to the maximum

length of interconnecting piping plus 50% for fittings. A more accurate

estimate may result in smaller sizes.

3. For applications with refrigerant line lengths greater than 100 ft, contact

Bryant representative.

Table 3C — Refrigerant Piping Sizes —

566E Units

LEGEND

*Field-supplied suction accumulator required.

NOTES:

1. Pipe sizes are based on a 2 F (1.1 C) loss for liquid lines and a 1.5 F

(0.8 C) loss for suction lines.

2. Pipe sizes are based on an equivalent length equal to the maximum

length of interconnecting piping plus 50% for fittings. A more accurate

estimate may result in smaller sizes.

3. For applications with refrigerant line lengths greater than 100 ft, contact

Bryant representative.

Table 4 — Refrigerant Piping Sizes, Double Suction

Risers — 566D150, 180 Units

NOTES:

1. See Fig. 5 for “A,” “B,” and “C” dimensions.

2. No double suction risers are needed for unit size 240.

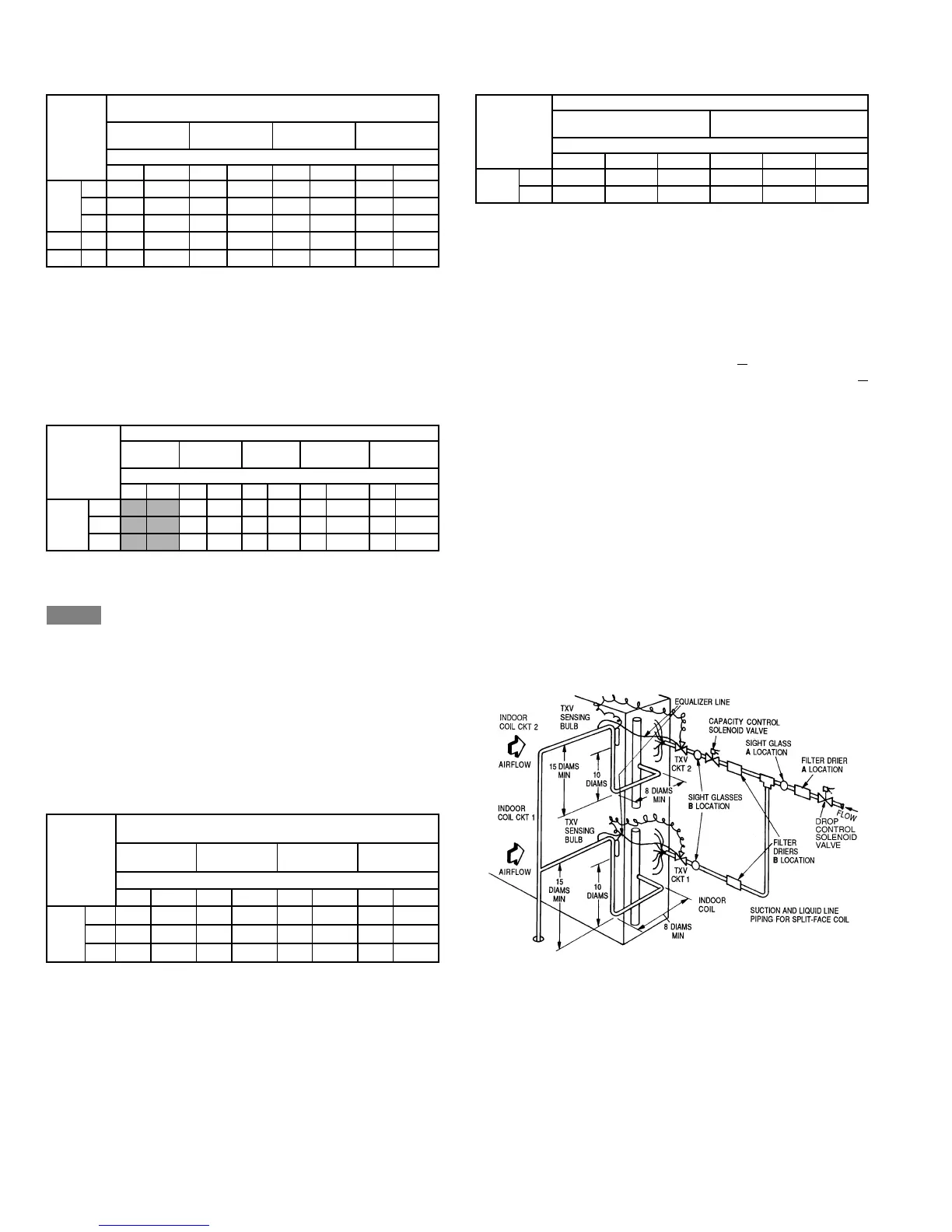

B. Install Filter Drier(s) and Moisture Indicator(s)

Every unit should have a filter drier and liquid-moisture

indicator (sight glass). Refer to Table 5. In some applications,

depending on space and convenience requirements, it may be

desirable to install 2 filter driers and sight glasses. One filter

drier and sight glass may be installed at A

locations in Fig. 7,

or, 2 filter driers and sight glasses may be installed at B

locations.

Select the filter drier for maximum unit capacity and mini-

mum pressure drop. Complete the refrigerant piping from

indoor unit to outdoor unit before opening the liquid and

suction lines at the outdoor unit.

C. Install Liquid Line Solenoid Valve — Solenoid Drop

It is recommended that a solenoid valve be placed in the

main liquid line (see Fig. 7) between condensing unit and fan

coil. Refer to Table 5. (A liquid line solenoid valve is required

when the liquid line length exceeds 75 ft.) This valve

prevents refrigerant migration (which causes oil dilution) to

the compressor during the off cycle at low outdoor ambient

temperatures. The solenoid should be wired in parallel with

the compressor contactor coil. This means of electrical

control is referred to as solenoid drop control.

UNIT

LINEAR LENGTH OF INTERCONNECTING PIPING —

FT (m)

0-25

(0-7.5)

26-50

(7.8-15)

51-75

(15.3-23)

76-100*

(23.3-30)

Line Size (in. OD)

LSLSLSLS

569D

072

3

/

8

1

1

/

8

3

/

8

1

1

/

8

3

/

8

1

1

/

8

3

/

8

1

1

/

8

090

3

/

8

1

1

/

8

3

/

8

1

1

/

8

3

/

8

1

1

/

8

3

/

8

1

1

/

8

120

1

/

2

1

3

/

8

1

/

2

1

3

/

8

1

/

2

1

3

/

8

1

/

2

1

3

/

8

576C

120

1

/

2

1

3

/

8

1

/

2

1

3

/

8

1

/

2

1

3

/

8

1

/

2

1

3

/

8

569F 120 (2)

3

/

8

(2) 1

1

/

8

(2)

3

/

8

(2) 1

1

/

8

(2)

3

/

8

(2) 1

1

/

8

(2)

3

/

8

(2) 1

1

/

8

UNIT

LENGTH OF INTERCONNECTING PIPING, FT (M)

0-15

(0-4.5)

16-25

(4.8-7.5)

26-50

(7.8-15)

51-75

(15.3-23)

76-100*

(23.3-30)

Line Size (in. OD)

LSLSLSLSLS

566D

150

1

/

2

1

1

/

8

1

/

2

1

3

/

8

5

/

8

1

3

/

8

5

/

8

1

5

/

8

†

5

/

8

1

5

/

8

†

180

1

/

2

1

3

/

8

5

/

8

1

3

/

8

5

/

8

1

5

/

8

7

/

8

1

5

/

8

7

/

8

2

1

/

8

†

240

5

/

8

1

5

/

8

5

/

8

1

5

/

8

7

/

8

1

5

/

8

7

/

8

2

1

/

8

7

/

8

2

1

/

8

L—Liquid

S—Suction

UNIT

LINEAR LENGTH OF INTERCONNECTING PIPING

FT (M)

0-25

(0-7.5)

26-50

(7.8-15)

51-75

(15.3-23)

76-100*

(23.3-30)

Line Size (in. OD)

LSLSLSLS

566E

150

1

/

2

1

1

/

8

1

/

2

1

1

/

8

1

/

2

1

1

/

8

1

/

2

1

3

/

8

180

1

/

2

1

3

/

8

1

/

2

1

3

/

8

1

/

2

1

3

/

8

5

/

8

1

3

/

8

240

1

/

2

1

3

/

8

1

/

2

1

3

/

8

5

/

8

1

3

/

8

5

/

8

1

3

/

8

L—Liquid

S—Suction

UNIT

LENGTH OF INTERCONNECTING PIPING, FT (M)

50-75

(15-23)

76-100

(23.3-30)

Line Size (in. OD)

ABCABC

566D

150 1

1

/

8

1

3

/

8

1

5

/

8

1

1

/

8

1

3

/

8

1

5

/

8

180 ———1

3

/

8

1

5

/

8

2

1

/

8

LEGEND

TXV — Thermostatic Expansion Valve

Fig. 7 — Location of Sight Glass(es)

and Filter Driers

Loading...

Loading...