—20—

NOTE: The crankcase will be slightly pressurized. Do not

remove the plug, or the entire oil charge will be lost.

Small amounts of oil can be removed through the oil pump

discharge connection while the compressor is running.

C. Start Unit

The field disconnect is closed, the fan circuit breaker is

closed, and the space thermostat is set above ambient so that

there is no demand for cooling. Only the crankcase heater

will be energized.

Next, close the compressor circuit breaker and then reset

space thermostat below ambient so that a call for cooling is

ensured.

NOTE: Do not use circuit breaker to start and stop the com-

pressor except in an emergency.

After starting, there is a delay of at least 3 seconds before

compressor starts.

D. Adjust Refrigerant Charge

Unit must be charged in Cooling mode only. Refer to Cooling

Charging Charts, Fig. 14-18 and to Table 7 for maximum

charge level. Vary refrigerant until the conditions of the

chart are met. Note that charging charts are different from

type normally used. Charts are based on charging the units

to the correct subcooling for the various operating conditions.

Accurate pressure gage and temperature sensing device are

required. Connect the pressure gage to the service port on

the liquid line service valve. Mount the temperature sensing

device on the liquid line, close to the liquid line service valve

and insulate it so that outdoor ambient temperature does not

affect the reading. Indoor airflow must be within the normal

operating range of the unit. Operate unit a minimum of

15 minutes. Ensure pressure and temperature readings have

stabilized. Plot liquid pressure and temperature on chart

and add or reduce charge to meet curve. Adjust charge to

conform with charging chart, using the liquid pressure and

temperature to read chart.

If the sight glass is cloudy, check refrigerant charge again.

Ensure all fans are operating. Also ensure maximum allow-

able liquid lift has not been exceeded. If charged per chart

and if the sight glass is still cloudy, check for a plugged filter

drier or a partially closed solenoid valve. Replace or repair,

as needed.

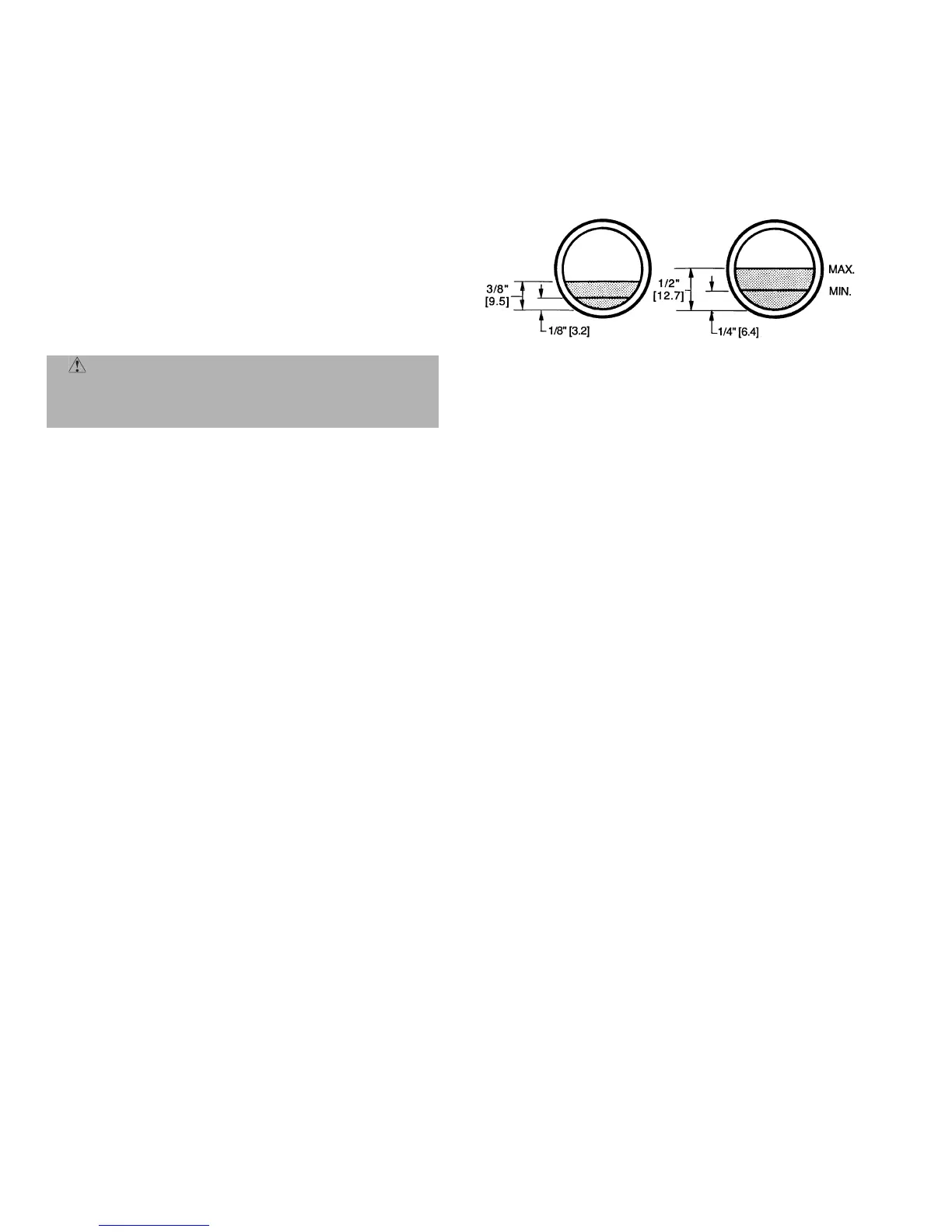

E. Check Compressor Oil Level

After adjusting the refrigerant charge, allow the compressor

to run fully loaded for 20 minutes. Running oil level should

be within view of the crankcase sight glass. Stop the com-

pressor at the field power supply disconnect and check the

crankcase oil level. Add oil only if necessary to bring the oil

into view in the sight glass. If oil is added, run the compres-

sor for an additional 10 minutes, then stop and check oil

level. If the level remains low, check the piping system for

proper design for oil return; also, check the system for leaks.

If the initial check shows too much oil (too high in the sight

glass) remove oil to proper level. See Preliminary Oil

Charge, this page, for proper procedure for adding and

removing oil. See Fig. 19.

When the above checks are complete, repeat the procedure

with the unit operating at minimum load conditions.

Unload the compressor by turning the control set point

adjustment nut counterclockwise until the adjustment nut

stops. The unloader is now at 0 psig set point. If electric actu-

ated unloaders are installed, energize the solenoid to unload

the compressor.

Return unloader to original setting after checks are complete.

F. Final Checks

Ensure all safety controls are operating, control panel covers

are on, and the service panels are in place.

OPERATING SEQUENCE

I. COOLING

A. 569D072-120, 576C090-120 Cooling

At start-up, the thermostat calls for cooling. With all safety

devices satisfied, the compressor contactor and fan contactor

energize, causing the compressor and outdoor-fan motor to

operate. Contacts energize, allowing the field-supplied and

field-installed indoor-fan contactor to function. A field-

supplied and field-installed liquid line valve also opens,

allowing the system to function in Cooling mode. As cooling

demand is satisfied, the thermostat contacts break, deener-

gizing the contactor and causing the system to shut off. The

liquid line solenoid valve closes, minimizing the potential for

refrigerant migration. The compressor does not restart until

the thermostat again calls for cooling. The system is pro-

tected with a safety circuit so that the system will not start if

a fault exists (i.e., high-pressure or discharge gas tempera-

ture [569D090 and 120 only] fault). To reset the safety cir-

cuit, set the thermostat to eliminate the cooling demand,

then return to original set point. This should be done only

once, and if system shuts down due to the same fault, deter-

mine the problem before attempting to restart the system.

B. 566D150-240 Cooling

When the first stage of cooling thermostat closes, the timer

starts. After approximately 3 seconds, the timer activates

the compressor and fan motor no. 1 contactors. When the liq-

uid pressure builds to approximately 257 psig, fan motor

no. 2 is energized.

When there is demand for additional cooling capacity, the

second stage of the cooling thermostat closes, energizing a

field-supplied liquid line solenoid (LLS) valve, which opens.

This increases the suction pressure, causing the compressor

to operate at higher capacity (compressor loads).

When the fan switch is set at AUTO, the indoor-air fan cycles

with the compressor. When the switch is set at CONT, the

indoor-air fan runs continuously.

At shutdown, the Time Guard II timer prevents the compres-

sor from restarting for approximately 5 minutes.

In addition, an LLS valve wired in parallel with the com-

pressor contactor coil shuts off the liquid line to prevent

CAUTION: Never charge liquid into the low-pres-

sure side of system. Do not overcharge. During charg-

ing or removal of refrigerant, be sure indoor-fan

system is operating.

566D240

(06E COMPRESSOR)

566D150,180 AND

576C090-120

(06D COMPRESSOR)

Fig. 19 — Operating Oil Levels

Loading...

Loading...