—19—

H. Final Checks

Ensure all safety controls are operating, control panel covers

are on, and the service panels are in place.

Table 7 — Maximum Refrigerant Charge

NOTE: 569F120 has 2 charges, one per circuit.

II. 576C, 566D UNITS

Compressor crankcase heater must be on for 24 hours before

start-up. After the heater has been on for 24 hours, the unit

can be started. If no time has elapsed since the preliminary

charge step has been completed, it is unnecessary to wait the

24-hour period.

A. Preliminary Checks

1. Ensure that compressor service valves are back-

seated.

2. Verify that each compressor floats freely on its

mounting springs.

3. Check that electric power supply agrees with unit

nameplate data.

4. Verify that compressor crankcase heater is securely

in place.

5. Check that compressor crankcase heater has been on

at least 24 hours.

6. Note that compressor oil level is visible in the sight

glass.

7. Recheck for leaks using same procedure as previously

outlined in Pre-Start-Up section, Leak Test and

Dehydration.

8. If any leaks are detected, evacuate and dehydrate as

previously outlined in Pre-Start-Up section, Leak

Test and Dehydration.

9. All internal wiring connections must be tight, and all

barriers and covers must be in place.

B. Preliminary Oil Charge

Compressor is factory charged with oil (see Tables 1A-1C).

When oil is checked at start-up, it may be necessary to add or

remove oil to bring it to the proper level. One recommended

oil level adjustment method follows:

Add Oil

Close suction service valve and pump down crankcase to

2 psig. (Low-pressure switch must be jumpered.) Wait a few

minutes and repeat until pressure remains steady at 2 psig.

Remove oil fill plug above the oil level sight glass, add oil

through plug hole, and replace plug. Run compressor for

20 minutes and check oil level. See Fig. 19.

NOTE: Use only Bryant approved compressor oil. Approved

sources are:

Petroleum Specialties Inc.. . . . . . . . . . . . . . . . . . . Cryol 150A

Texaco, Inc.. . . . . . . . . . . . . . . . . . . . . . . . . . . . Capella WF-32

Witco Chemical Co. . . . . . . . . . . . . . . . . . . . . . . . .Suniso 3GS

Do not use oil that has been drained out, or oil that has been

exposed to atmosphere.

Remove Oil

Pump down compressor to 2 psig. Loosen the

1

/

4

-in. pipe plug

at the compressor base and allow the oil to seep out past the

threads of the plug.

UNIT R-22 (lb)

569D

072

090

120

17.3

34.2

34.2

576C

090

102

120

34.2

569F 120 (2) 17.1

566D

150

180

240

40.3

39.8

39.8

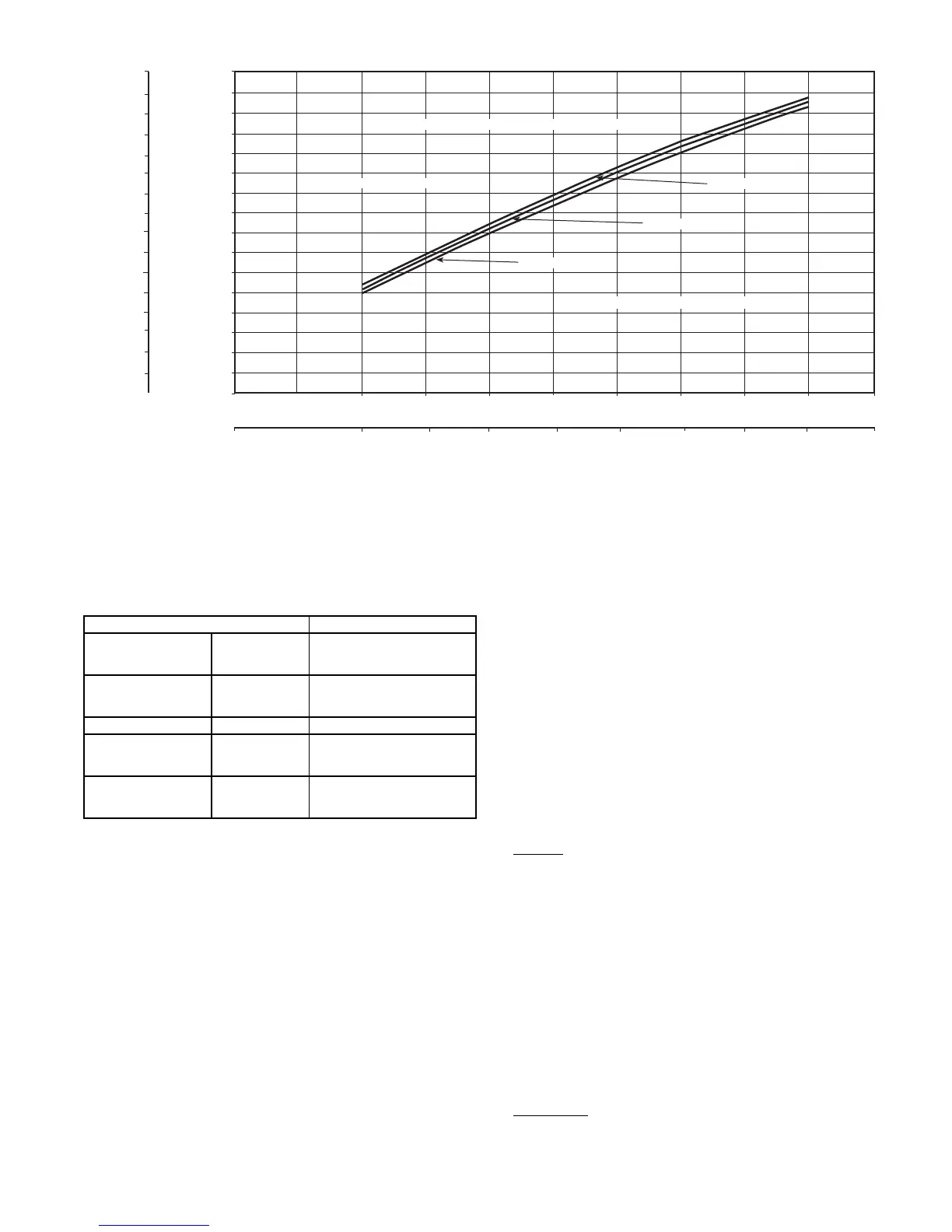

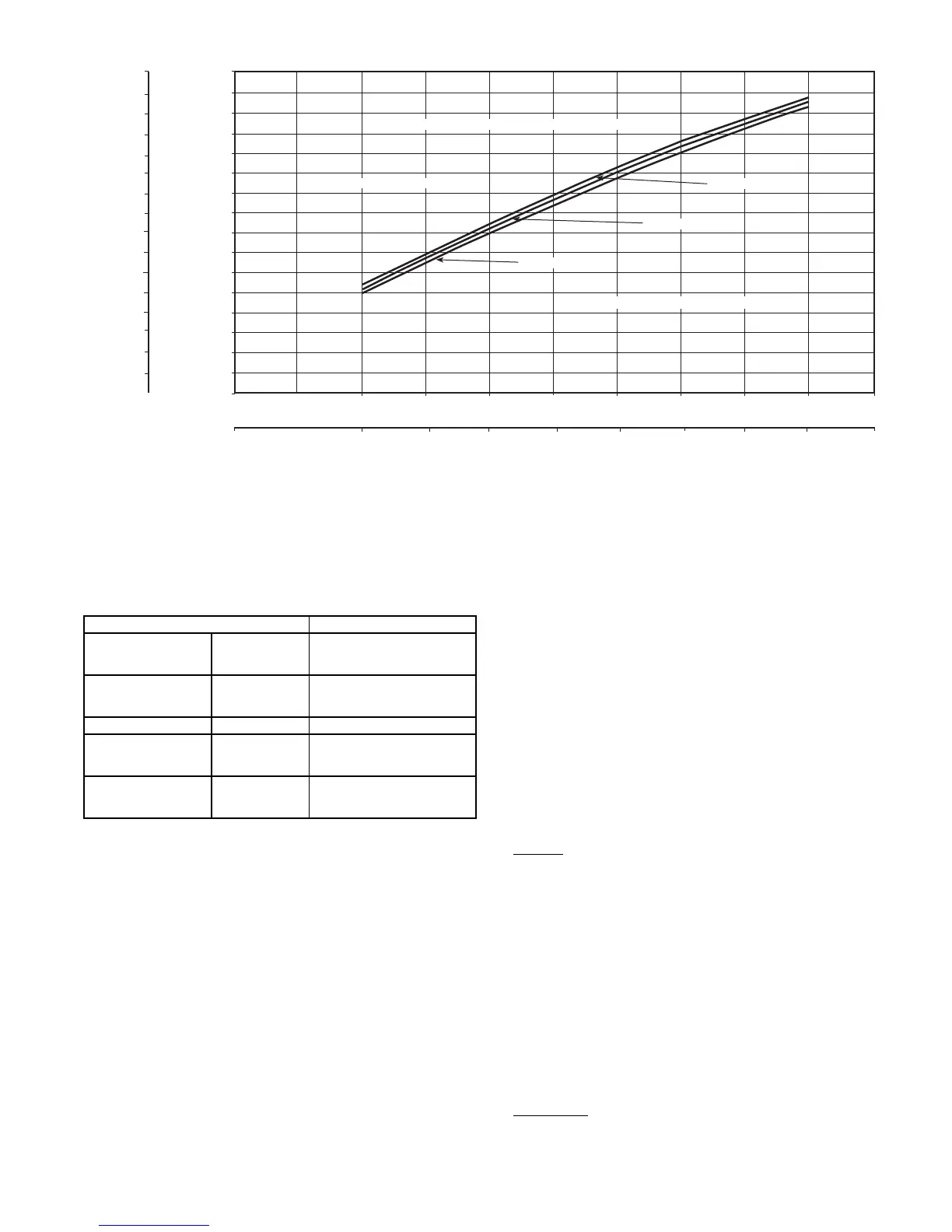

566E

150

180

240

48.0

556E240

566E180

566E150

BOTH OUTDOOR FANS MUST BE OPERATING

REDUCE CHARGE IF BELOW CURVE

ADD CHARGE IF ABOVE CURVE

LIQUID TEMPERATURE AT LIQUID VALVE (C)

LIQUID TEMPERATURE AT LIQUID VALVE (F)

160.00

150.00

140.00

130.00

120.00

110.00

100.00

90.00

80.00

70.00

71

66

60

64

49

43

38

32

27

21

16

10

4

-1

-7

-12

60.00

50.00

40.00

30.00

20.00

10.00

0.00

100

690

150

200

1030

1379

1720

250 300

2069

350 400

2410

2758

3100

450 500

3448

LIQUID PRESSURE AT LIQUID VALVE (psig)

LIQUID PRESSURE AT LIQUID VALVE (kPa)

Fig. 18 — 566E150-240 Charging Chart

Loading...

Loading...