—9—

II. RIG AND MOUNT THE UNIT

A. Rigging

These units are designed for overhead rigging. Refer to rig-

ging label for preferred rigging method. Spreader bars are

not required if top crating is left on unit. All panels must be

in place when rigging. As further protection for coil faces,

plywood sheets may be placed against sides of unit, behind

cables. Run cables to a central suspension point so that angle

from the horizontal is not less than 45 degrees. Raise and set

unit down carefully.

If it is necessary to roll the unit into position, mount the unit

on longitudinal rails, using a minimum of 3 rollers. Apply

force to the rails, not the unit. If the unit is to be skidded into

position, place it on a large pad and drag it by the pad. Do

not apply any force to the unit.

Raise from above to lift unit from the rails or pad when unit

is in final position.

After unit in position, remove all shipping materials and top

crating.

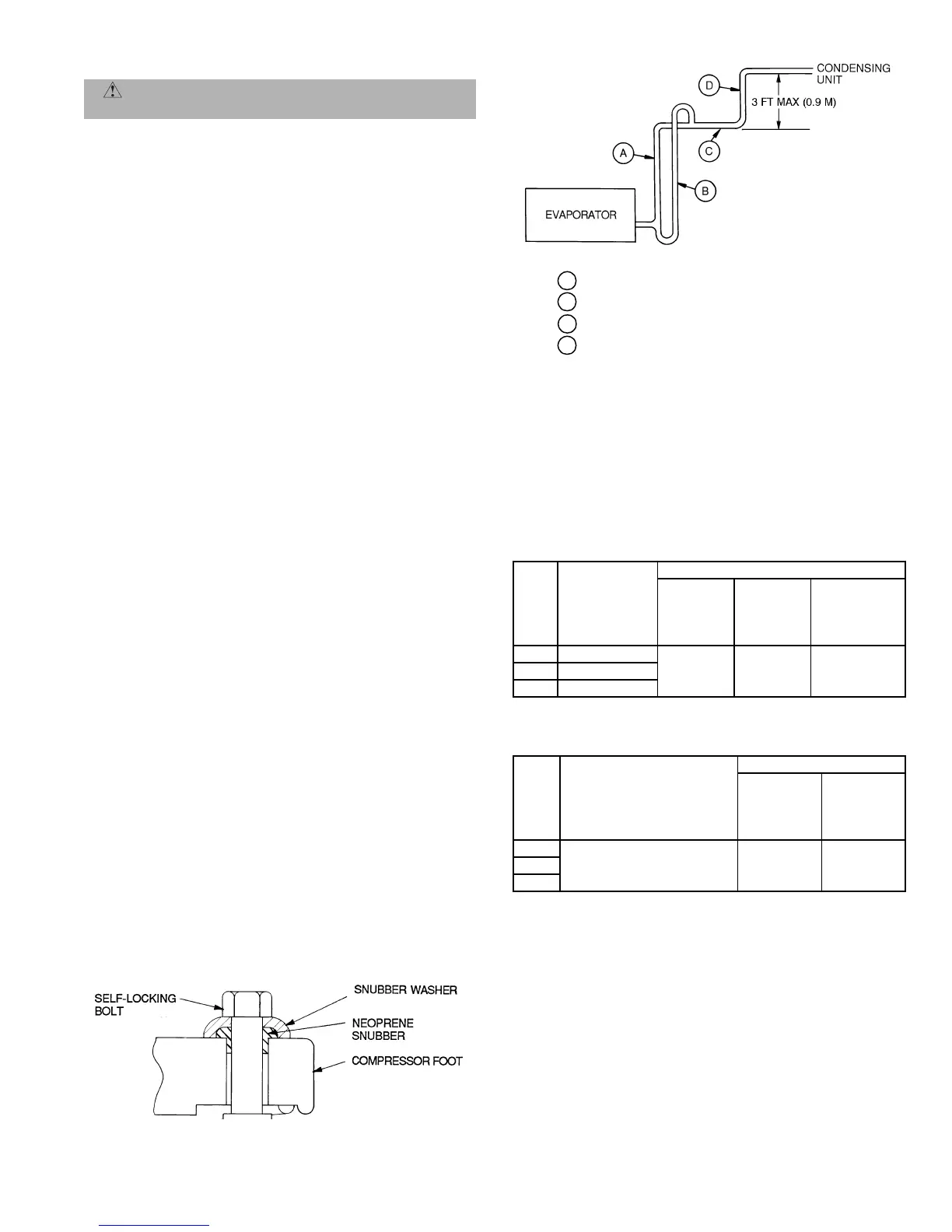

B. Compressor Mounting

As shipped, the compressor is held tightly in place by self-

locking bolts. Before starting unit, loosen self-locking

bolts until the snubber washer can be moved side-

ways with finger pressure. Do not remove shipping

bolts. See Fig. 5.

III. COMPLETE REFRIGERANT PIPING CONNECTIONS

IMPORTANT: DO NOT bury refrigerant piping underground.

IMPORTANT: A refrigerant receiver is not provided with the

unit. Do not install a receiver.

A. Size Refrigerant Lines

Consider the length of piping required between outdoor unit

and indoor unit (evaporator), the amount of liquid lift, and

compressor oil return. See Tables 2A-4. Refer to indoor unit

installation instructions for additional information.

IMPORTANT: Use the piping data in Tables 2A-4 as a

general guide only. For 569D, 576C, 569F applications with

liquid lift greater than 20 ft, use

5

/

8

-in. liquid line. Maximum

lift is 60 ft.

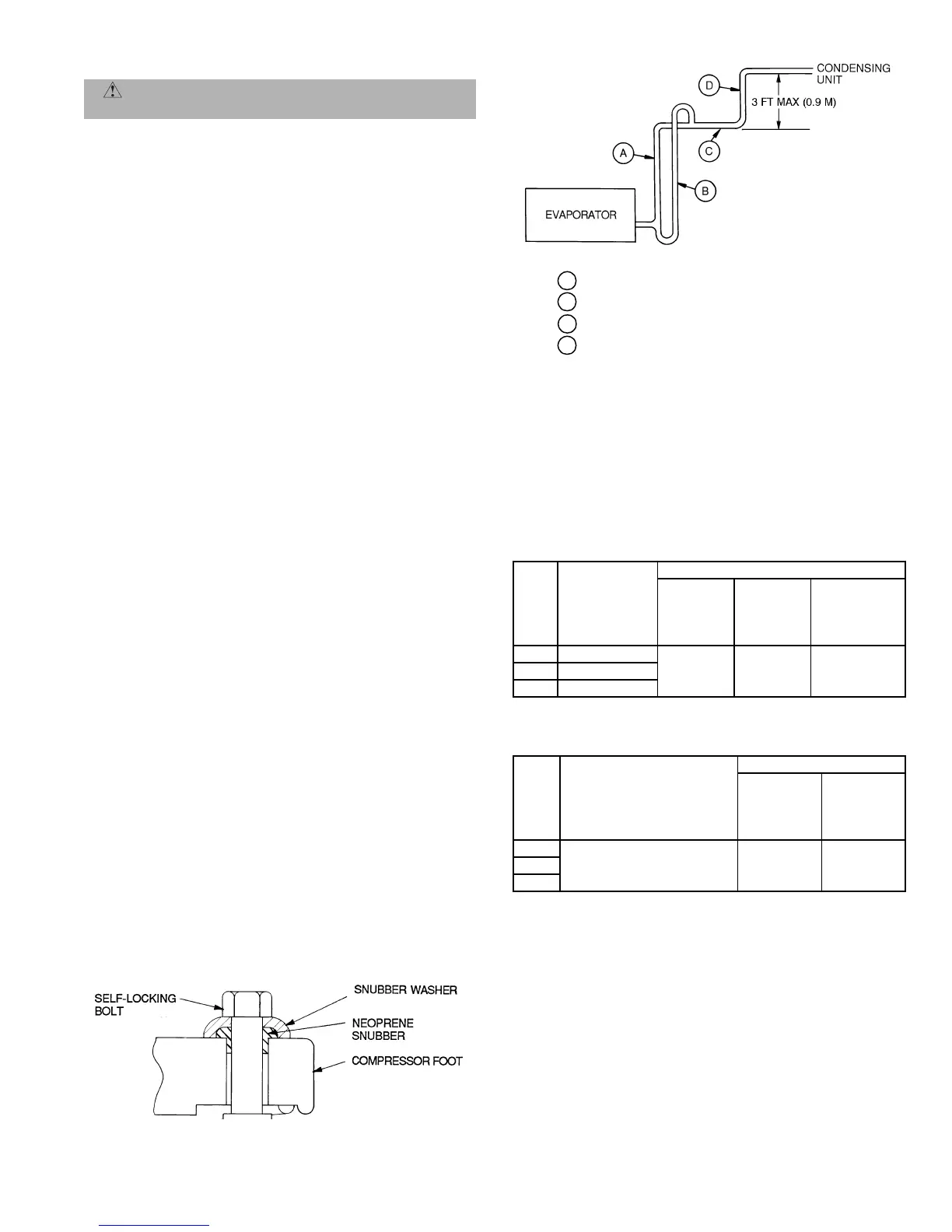

Condensing units with multiple-step unloading may require

double suction risers to assure proper oil return at minimum

load operating condition. See Tables 3A-4 and Fig. 6. Reduc-

tion of evaporator coil surface should be analyzed to provide

sufficient refrigerant velocity to return oil to the compressor.

Liquid line solenoid valves may be used in certain situations

to accomplish this. Hot gas bypass, if used, should be intro-

duced before the evaporator.

Note that refrigerant suction piping should be insulated.

Table2A—LiquidLineData—

566D150-240 Units

Table2B—LiquidLineData—

566E150-240 Units

*Inlet and outlet.

NOTE: Data shown is for units operating at 45 F (7.2 C) saturated suc-

tion and 95 F (35 C) entering air.

CAUTION: Be sure unit panels are securely in

place prior to rigging.

UNIT

566D

MAXIMUM

ALLOWABLE

LIQUID LIFT

ft (m)

LIQUID LINE

Maximum

Allowable

Pressure

Drop

psig (kPa)

Maximum

Allowable

Temp.

Loss

F(C)

Filter Drier

and

Sight Glass

Flare Conn.*

in.

150 67 (20.4)

7 (48.3) 2 (1.1)

5

/

8

180 82 (25.0)

240 87 (26.5)

UNIT

566E

MAXIMUM

ALLOWABLE

LIQUID LIFT

ft (m)

LIQUID LINE

Maximum

Allowable

Pressure

Drop

psig (kPa)

Maximum

Allowable

Temp.

Loss

F(C)

150

60 (18) 7 (48) 2 (1)180

240

LEGEND

A — Suction Riser

Without

Tr ap

B — Suction Riser

With

Trap

C — Suction Line to Condensing Unit

D — Short Vertical Riser into Condensing Unit:

566D150,180 — 1

3

/

8

in. OD

566D240 — 1

5

/

8

in. OD

Fig. 6 — Suction Line Piping

Fig. 5 — Compressor Mounting

Loading...

Loading...