1. Operate unit a minimum of 10 minutes before checking

charge.

2. Measure liquid service valve pressure by attaching an

accurate gage to service port.

3. Measure liquid line temperature by attaching an accurate

thermistor type or electronic thermometer to liquid line near

outdoor coil.

4. Refer to Table 8 for required subcooling temperature.

5. Refer to Table 7. Find the point where required subcooling

temperature intersects measured liquid service valve pres-

sure.

6. To obtain required subcooling temperature at a specific

liquid line pressure, add refrigerant if liquid line tempera-

ture is higher than indicated or reclaim refrigerant if

temperature is lower. Allow a tolerance of ± 3°F.

XII. SYSTEM FUNCTIONS AND SEQUENCE OF OPERA-

TION

The outdoor unit control system has special functions. The

following is an overview of the two-speed control functions:

A. COOLING OPERATION

This product utilizes a 2-stage cooling indoor thermostat. With a

call for first stage cooling (Yl), the outdoor fan and low capacity

compressor are energized. If low capacity cannot satisfy cooling

demand, high capacity is energized (Yl and Y2 or Y2 only) by the

second stage of indoor thermostat. After second stage is satisfied,

the unit returns to low-speed operation until first stage is satisfied

or until second stage is required again. When both one stage and

two stage cooling are satisfied, the compressor will shut off.

NOTE: When two-speed unit is operating at low speed, system

vapor (suction) pressure will be higher than a standard single-

speed system or high-speed operation. This normal operation is

due to the reduced capacity operating with typically larger indoor

and outdoor coils.

NOTE: Outdoor fan motor will continue to operate for one

minute after compressor shuts off, when outdoor ambient is greater

than or equal to 100°F.

B. STATUS FUNCTION LIGHTS

A system control STATUS function light is located on the outdoor

unit control board (see Fig. 10). The STATUS light provides

signals for several system operations. See Table 9 for codes and

definitions. Table 9 also provides the order of signal importance.

NOTE: Only one code will be displayed on the outdoor unit

control board (the most recent, with the highest priority).

C. FACTORY DEFAULTS

Factory defaults have been provided in the event of failure of

outdoor air thermistor, coil thermistor, and/or furnace interface

jumper.

D. ONE MINUTE SPEED CHANGE TIME DELAY

When compressor changes speeds from high to low or low to high,

there is a 1 minute time delay before compressor restarts. The

outdoor fan motor remains running.

E. COMPRESSOR OPERATION

When the compressor operates in high capacity operation, the

motor rotates clockwise. Both the lower and upper pistons are

eccentric with the rotating crankshaft and both compress refriger-

ant. When the compressor operates in low capacity the motor

reverses direction (rotates counterclockwise). The lower piston

becomes idle since it is in line with the compressor crankshaft and

the upper piston which is eccentric with the rotating crankshaft

compresses refrigerant. The start and run windings are reversed.

F. CRANKCASE HEATER OPERATION

The two-speed control energizes crankcase heater during unit off

cycle.

G. OUTDOOR FAN MOTOR OPERATION

The outdoor unit control energizes outdoor fan any time compres-

sor is operating. The outdoor fan remains energized during the 1

minute speed change time delay and if a pressure switch or

compressor overload should trip. Outdoor fan motor will continue

to operate for one minute after the compressor shuts off when the

outdoor ambient is greater than or equal to 100°F.

H. COMPRESSOR VOLTAGE FAILURE (6 FLASHES)

The control senses the voltage of the compressor run winding. If

compressor voltage (Vc) is out of range (less than 90v or greater

than 600v), control shuts compressor off for 15 minutes with

outdoor fan running. After 15 minutes (provided there is a call for

Y1 or Y2), control attempts to start compressor. During this time,

a code of 6 flashes appears at control board. If Vc trip occurs 3

consecutive times during a Y1 request, then low capacity operation

is locked out and control responds to Y2 requests until a reset

occurs. If 3 consecutive trips occur in a combination of Yl and Y2

or all Y2 requests, then both low and high capacity operation will

be locked out. The compressor voltage failure (6 flashes) can be

caused by:

• compressor internal overload trip

• no 240 volt power supply to outdoor unit

• failed compressor contactor(s)

• failure of start relay to pick up properly.

I. PRESSURE SWITCH PROTECTION

The outdoor unit is equipped with high- and low-pressure

switches. If the control senses the opening of a high or low

pressure switch, it will respond as follows:

1. De-energize the compressor low or high speed contactor,

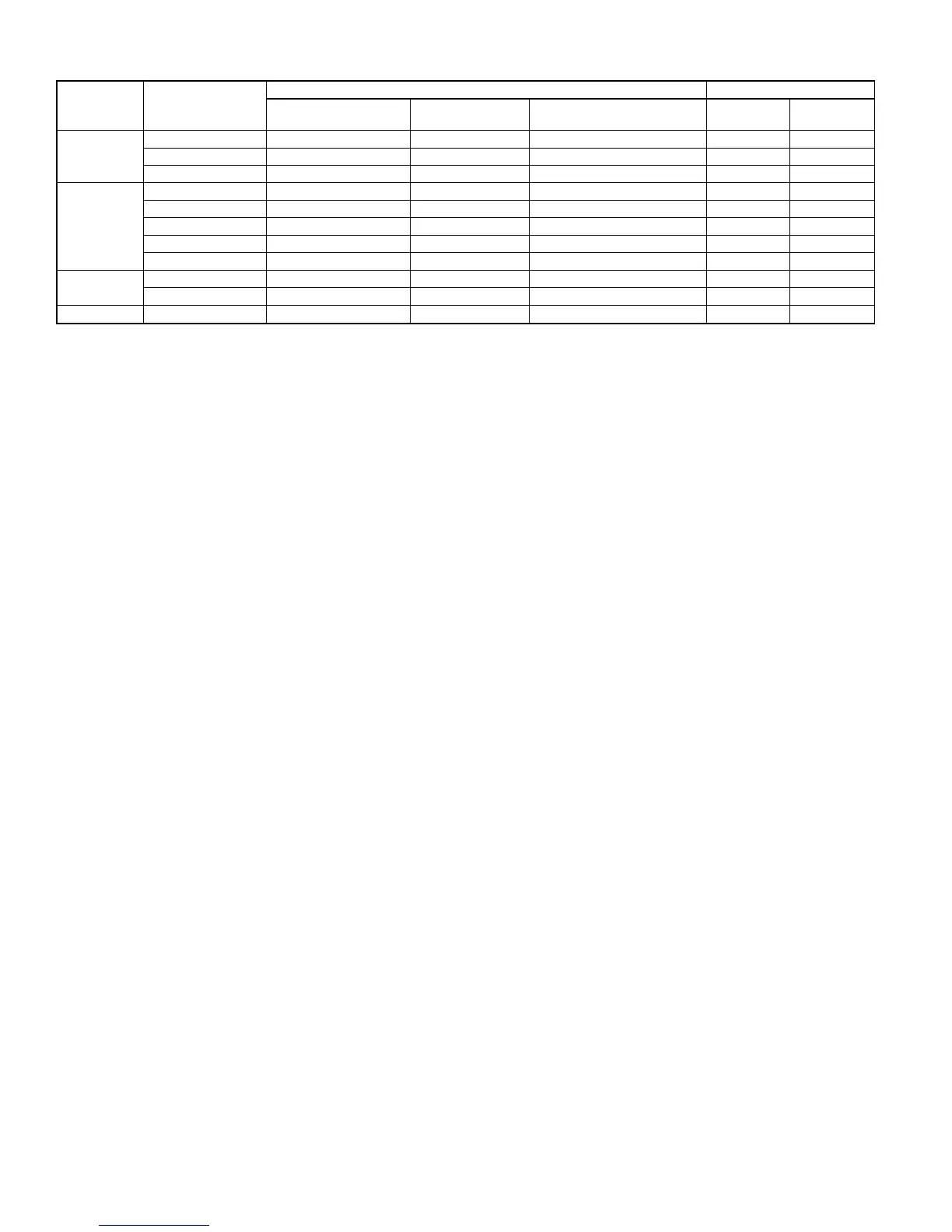

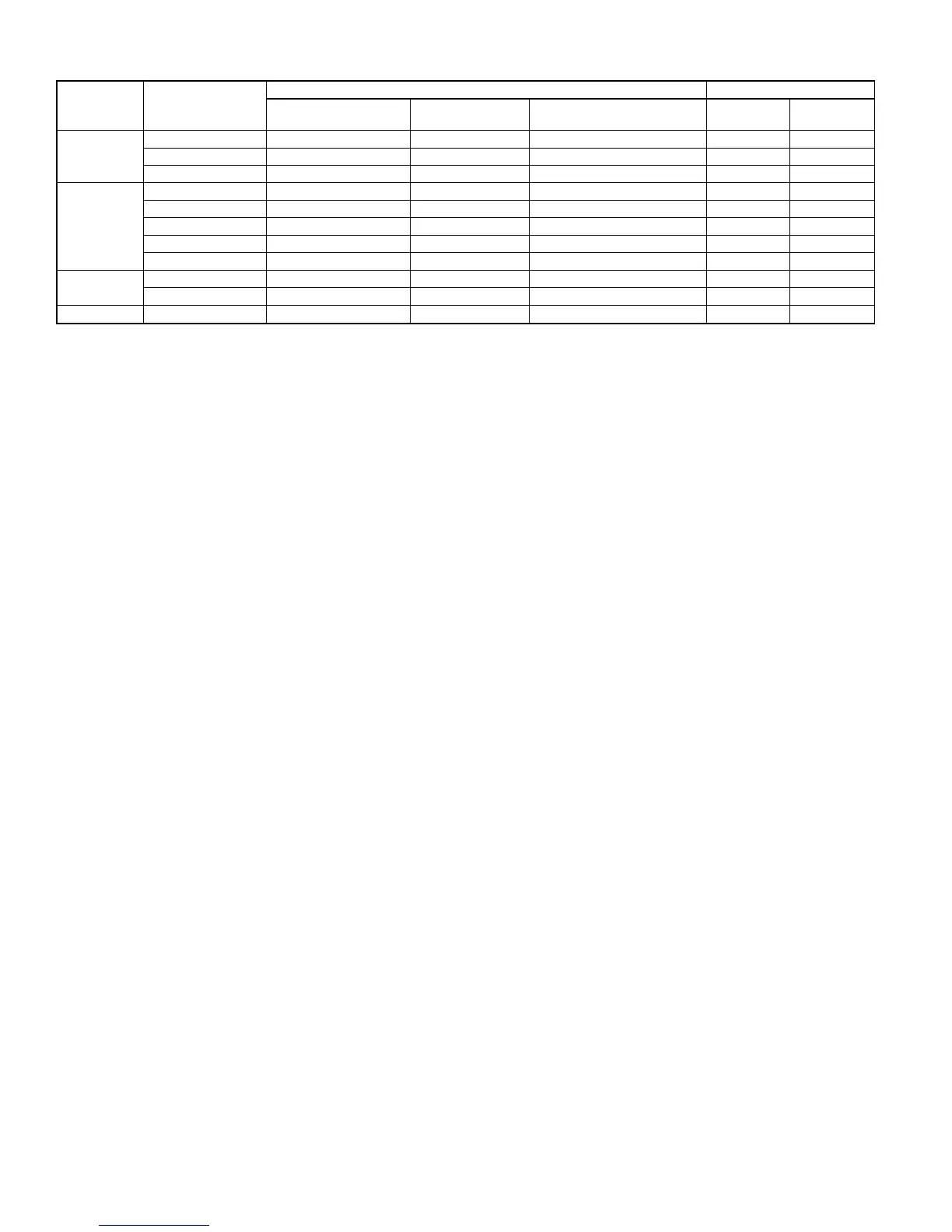

TABLE 6—AIRFLOW SELECTION FOR FK4C OR FV4A FAN COILS (CFM)

598B

UNIT

SIZE

FK4C/FV4A

EASY SELECT CONTROL BOARD CFM*

SYSTEM TYPE

(Orange Wire)

A/C TYPE

(Blue Wire)

AC/HP CFM ADJUST

(Black Wire)

High Low

024

001 AC 024 NOM 735 441

002 AC 024 NOM 735 441

003 AC 024 NOM 735 441

036

001 AC 036 NOM 1100 662

002 AC 036 NOM 1100 662

003 AC 036 NOM 1100 662

005 AC 036 NOM 1100 662

006 AC 036 NOM 1100 662

048

005 AC 048 NOM 1470 882

006 AC 048 NOM 1470 882

060 006 AC 060 NOM 1835 1103

* Airflow CFMs are given with AC/HP CFM ADJUST jumper set at NOM. Airflow can be adjusted 15 percent or −10 percent by selecting HI or LO, respectively.

—8—

Loading...

Loading...