15

shutoff valve before and during supply pipe pressure test. After

all connections have been made, purge lines and check for

leakage at furnace prior to operating furnace.

The gas supply pressure shall be within the maximum and

minimum inlet supply pressures marked on the rating plate with

the furnace burners ON and OFF.

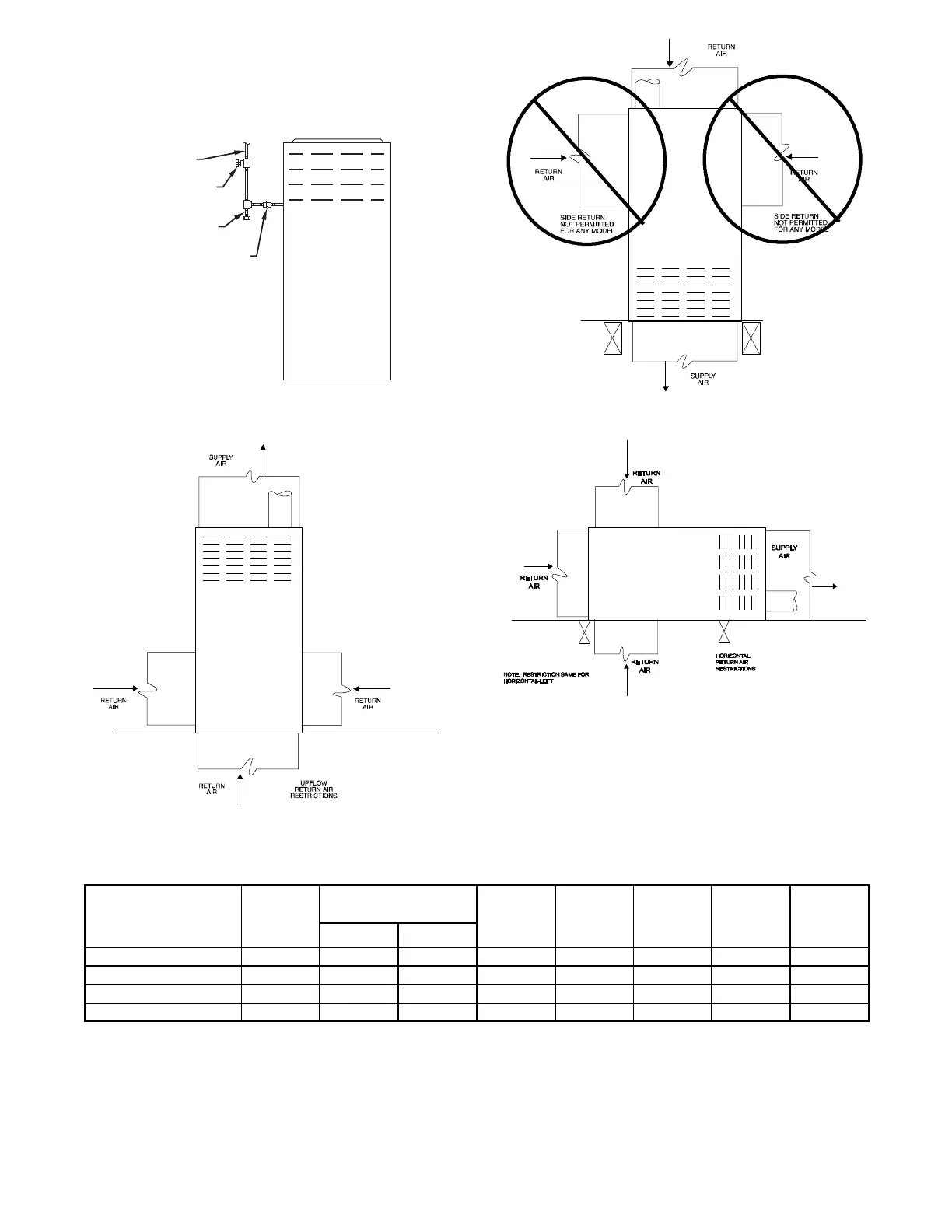

UNION

SEDIMENT

TRAP

MANUAL

SHUTOFF

VALVE

(REQUIRED)

GAS

SUPPLY

A02035

Fig. 18 -- Typical Gas Pipe Arrangement

A190364

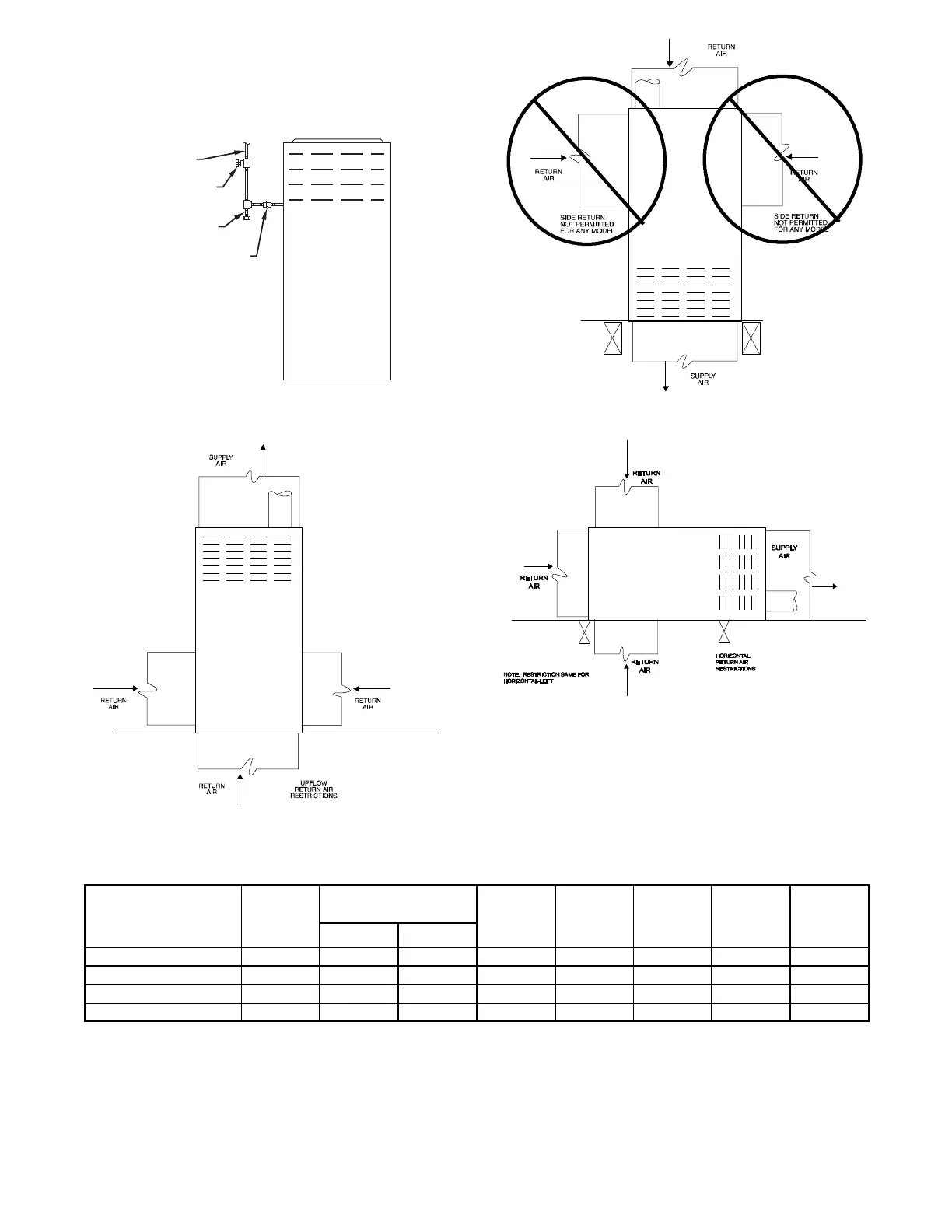

Fig. 19 -- Upflow Return Air Configura tions and Restrictions

A190365

Fig. 20 -- Downflow Return Air Configurations and Restric-

tions

A190366

Fig. 21 -- Horizontal Return Air Configurations and Restric-

tions

Table 7 – Electrical Data

Unit Size

Volts-

Hertz -

Phase

Operating Voltage*

Range

Maximum

Unit Amps

Unit

Ampacity#

Minimum

Wire Size

AWG

Maximum

Wire

Length‡ ft

(m)

Maximum

Fuse or

CKT BKR†

Amps

Maximum Minimum

36040E17 115-60-1 127 104 10.6 13.9 14 26 (8) 15

48060E17 115-60-1 127 104 10.6 13.9 14 26 (8) 15

60080E21 115-60-1 127 104 13.3 17.3 12 33 (10) 20

60100E21 115-60-1 127 104 13.3 17.3 12 33 (10) 20

* Permissible limits of the voltage range at which the unit operates satisfactorily .

# Unit ampacity = 125 percent of largest operating component’s full load amps plus 100 percent of all other potential operating components’ (EAC, humidifier,

etc.) full load amps.

{ Time---delay type is recommended.

} Length shown is as measured one way along wire path between unit and service panel for maximum 2 percent voltage drop.

Loading...

Loading...