—

9

—

III. STEP 3 — FIELD FABRICATE DUCTWORK

Secure all ducts to building structure. Use flexible duct con-

nectors between unit and ducts as required. Insulate and

weatherproof all external ductwork, joints, and roof openings

with counter flashing and mastic in accordance with applica-

ble codes.

Ducts passing through an unconditioned space must be insu-

lated and covered with a vapor barrier.

The 558F units with electric heat require a 1-in. clearance

for the first 24 in. of ductwork.

Outlet grilles must not lie directly below unit discharge.

NOTE: A 90-degree elbow must be provided in the ductwork

to comply with UL (Underwriters’ Laboratories) codes for

use with electric heat.

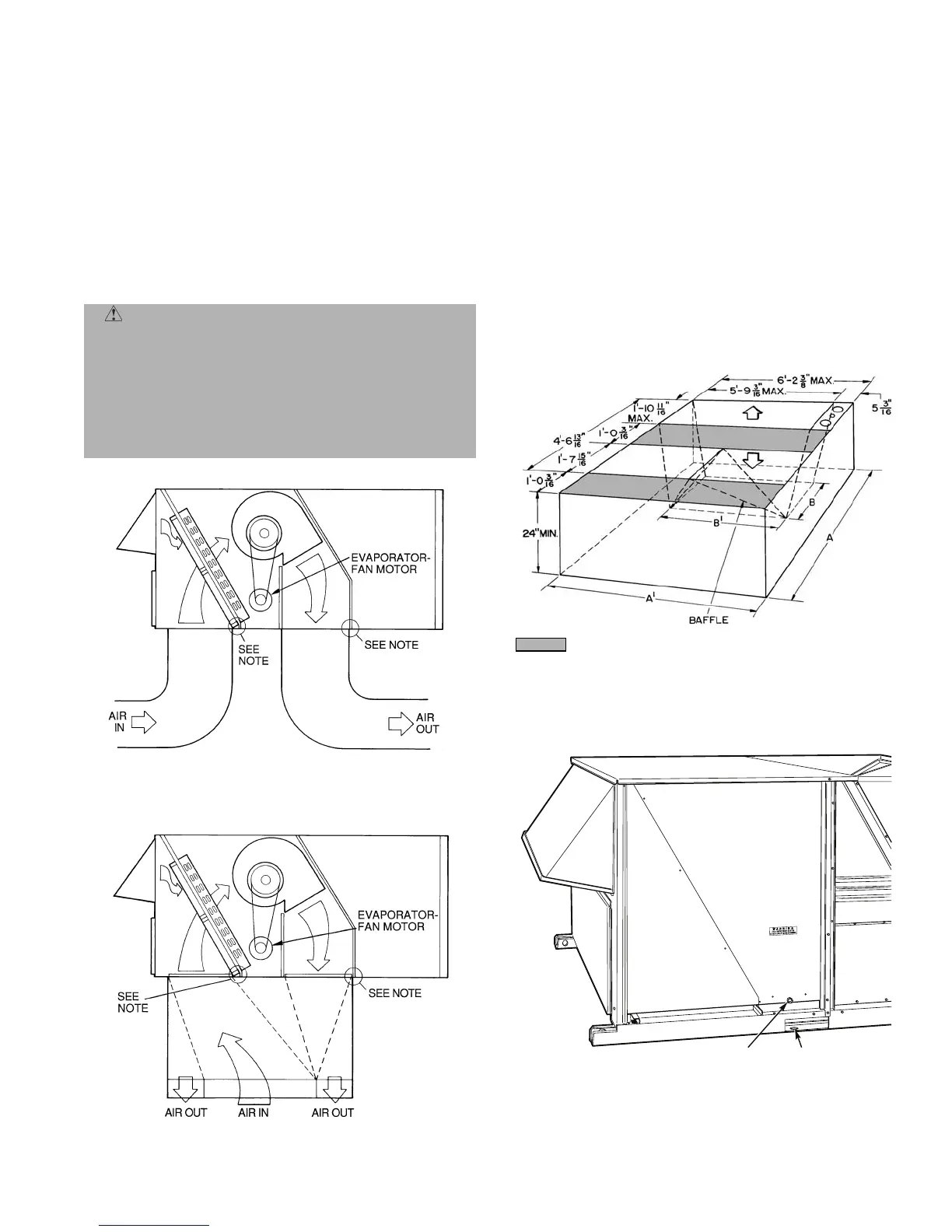

IV. STEP 4 — MAKE UNIT DUCT CONNECTIONS

Unit is shipped for through-the-bottom duct connections.

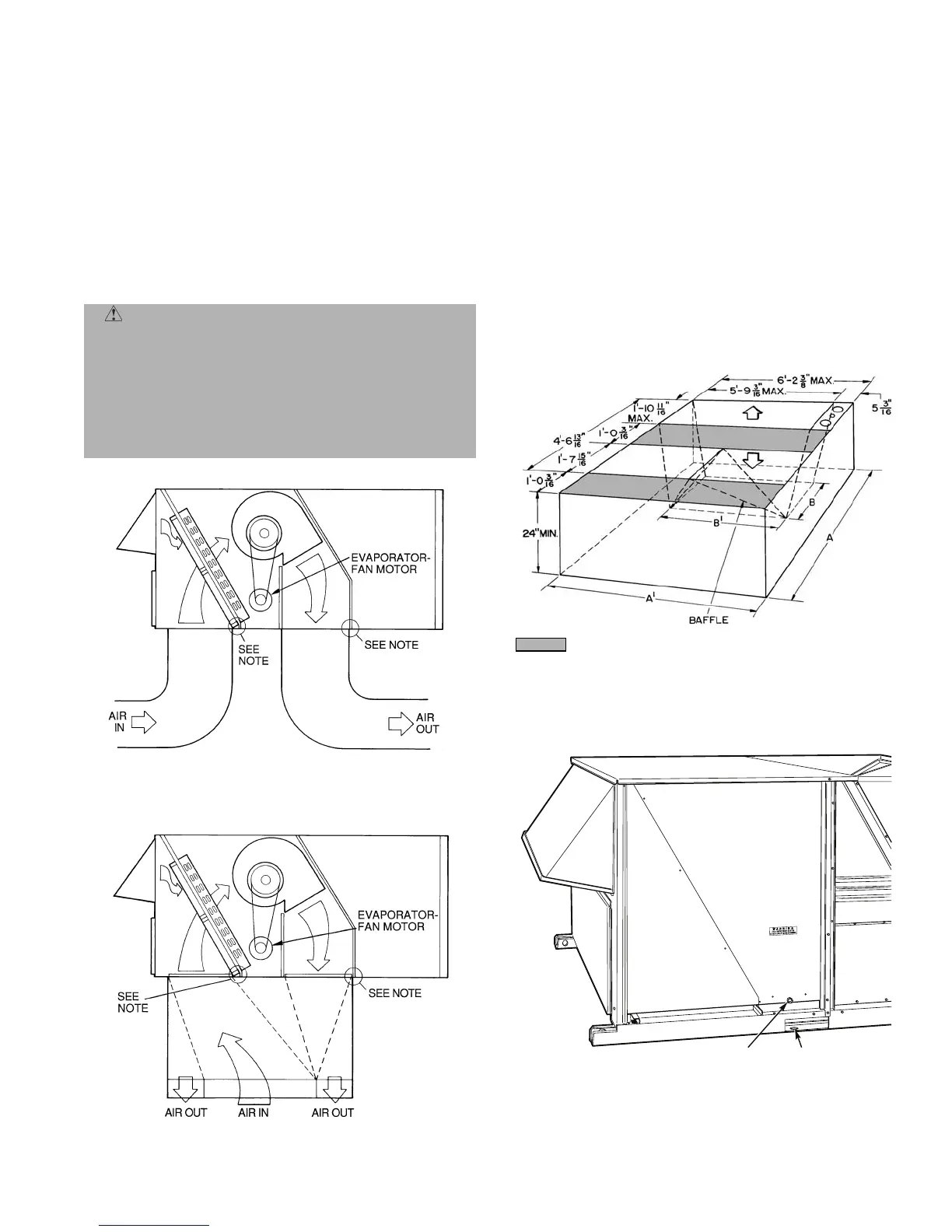

Ductwork openings are shown in Fig. 7. Field-fabricated con-

centric ductwork may be connected as shown in Fig. 8 and 9.

Attach all ductwork to roof curb and roof curb basepans.

Refer to installation instructions shipped with accessory roof

curb for more information.

V. STEP 5 — TRAP CONDENSATE DRAIN

See Fig. 4-6, and 10 for drain location. Plug is provided in

drain hole and must be removed when unit is operating. One

3

/

4

-in. half-coupling is provided inside unit evaporator sec-

tion for condensate drain connection. An 8

1

/

2

in. x

3

/

4

-in.

diameter nipple and a 2-in. x

3

/

4

-in. diameter pipe nipple are

coupled to standard

3

/

4

-in. diameter elbows to provide a

straight path down through holes in unit base rails (see

Fig. 11). A trap at least 4-in. deep must be used.

WARNING: For vertical supply and return units,

tools or parts could drop into ductwork and cause an

injury. Install a 90 degree turn in the return ductwork

between the unit and the conditioned space. If a

90 degree elbow cannot be installed, then a grille of

sufficient strength and density should be installed to

prevent objects from falling into the conditioned space.

Due to electric heater, supply duct will require

90 degree elbow.

NOTE:

Do not drill in this area; damage to basepan may result in water

leak.

Fig. 7 — Air Distribution — Thru-the-Bottom

NOTE:

Do not drill in this area; damage to basepan may result in water

leak.

Fig. 8 — Concentric Duct Air Distribution

3/4" FPT DRAIN

CONNECTION

1-3/8"

DRAIN HOLES

Shaded area indicates block-off panels.

NOTE:

Dimensions A, A

′,

and B, B

′

are obtained from field-supplied

ceiling diffuser.

Fig. 9 — Concentric Duct Details

Fig. 10 — Condensate Drain Details

(558F180,210 Shown)

Loading...

Loading...