186CNV: Installation Instructions

Manufacturer reserves the right to change, at any time, specifications and designs without notice and without obligations.

10

A200035

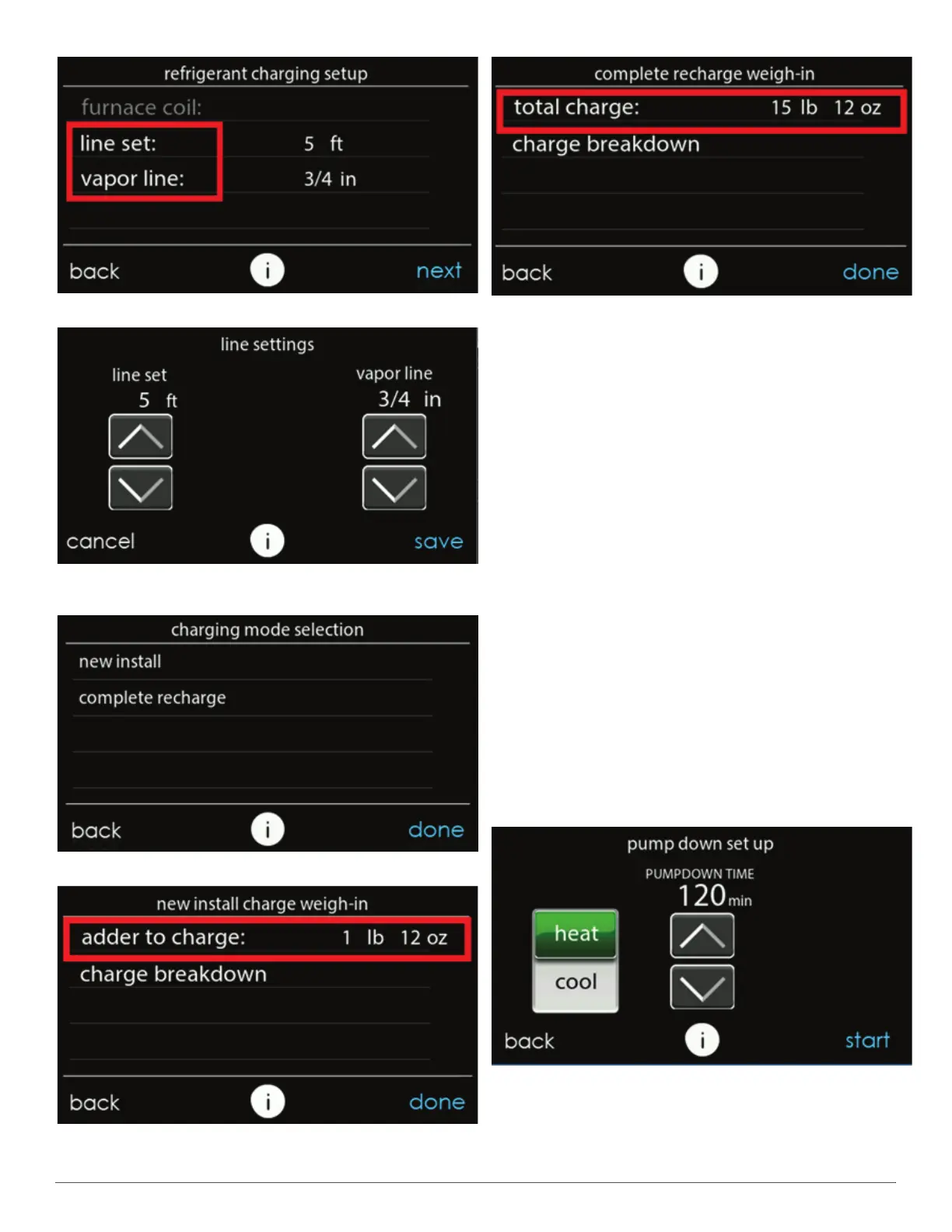

Fig. 16 – Select Line Set Length & Vapor Line Diameter

A200036

Fig. 17 – Adjust Line Set Length & Vapor Line Diameter that is

Installed

A200037

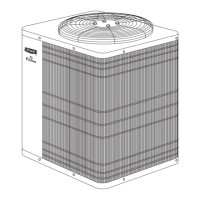

Fig. 18 – Charging Mode Selection

A200038

Fig. 19 – Additional Required Charge for New Installation

A200039

Fig. 20 – Total Charge Required for a Complete Charge

Step 12 – Pumpdown & Evacuation

Because this system has an inverter controlled compressor the

conventional procedure cannot be used to "pump down" and isolate the

refrigerant into the outdoor unit. The UI (User Interface) has provisions

to assist in performing this function. Pump Down

1. Connect gages to liquid and vapor or suction capillary service ports

to monitor operating pressures during and at completion of the

procedure.

2. In the "installation and service" menu of the UI (see Fig. 10), go to

"refrigerant charging" and then "pump down" (see Fig. 10 &

Fig. 11).

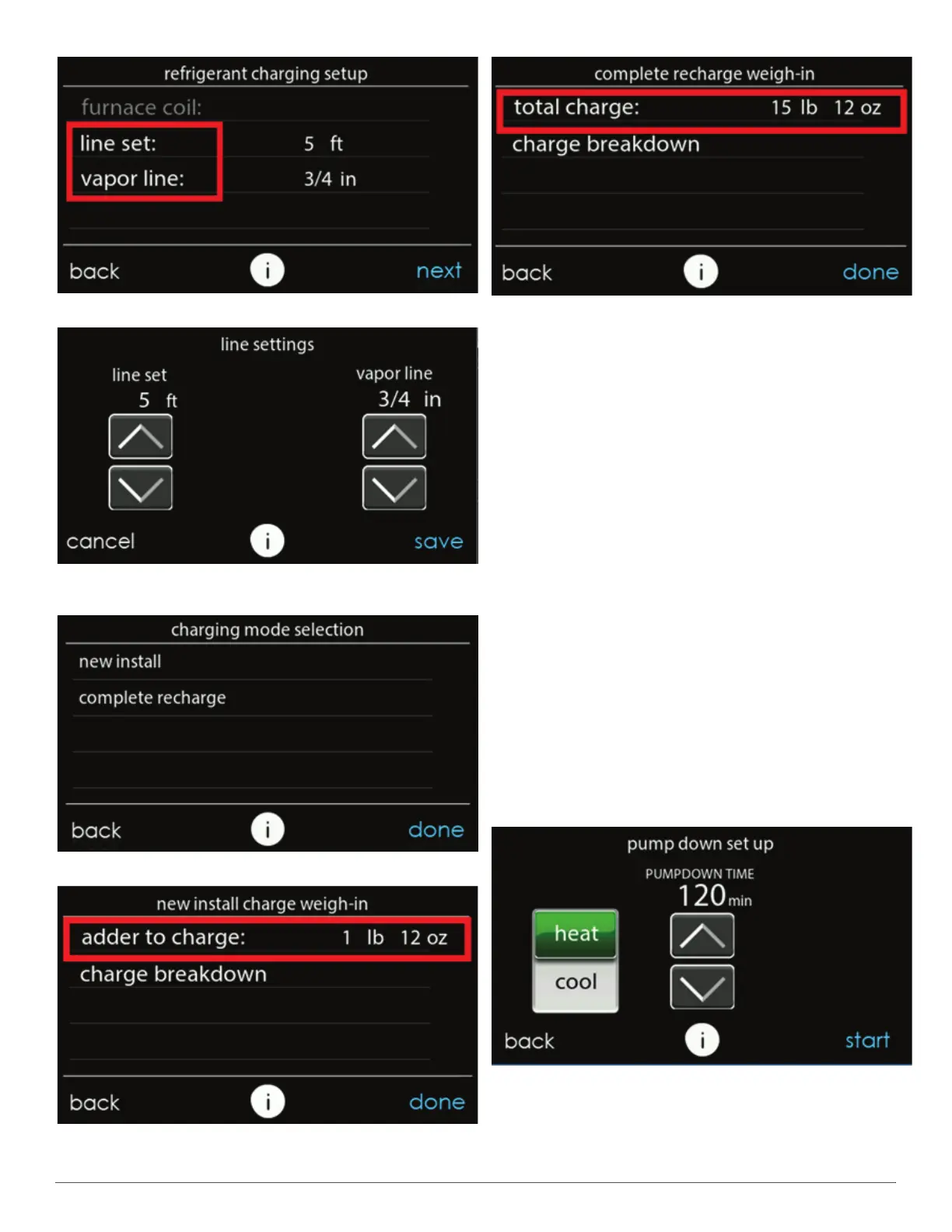

3. Pump down in COOL mode allows refrigerant to be isolated in

outdoor unit. Set desired time period. Default time period for the

procedure is 120 minutes. See Fig. 21.

4. Select Start on UI to begin the pumpdown process. Unit will begin

running in selected mode after a brief delay and a status screen will

be displayed. See Fig. 22.

5. Close the liquid service valve.

6. The unit will run with the low pressure protection set to indicate

pumpdown is complete when the suction pressure drops below 20

psig. Compressor protections are still active to prevent damage to

the compressor or inverter (high pressure, high current, etc.).

7. Once system indicates pumpdown complete or failure to complete

shutdown, close vapor service valve.

8. A recovery system will be required to remove final quantity of

refrigerant from indoor coil and line set.

9. Remove power from indoor and outdoor unit prior to servicing unit.

A200040

Fig. 21 – Pump Down Setup Screen

Loading...

Loading...