186CNV: Installation Instructions

Manufacturer reserves the right to change, at any time, specifications and designs without notice and without obligations.

11

A200041

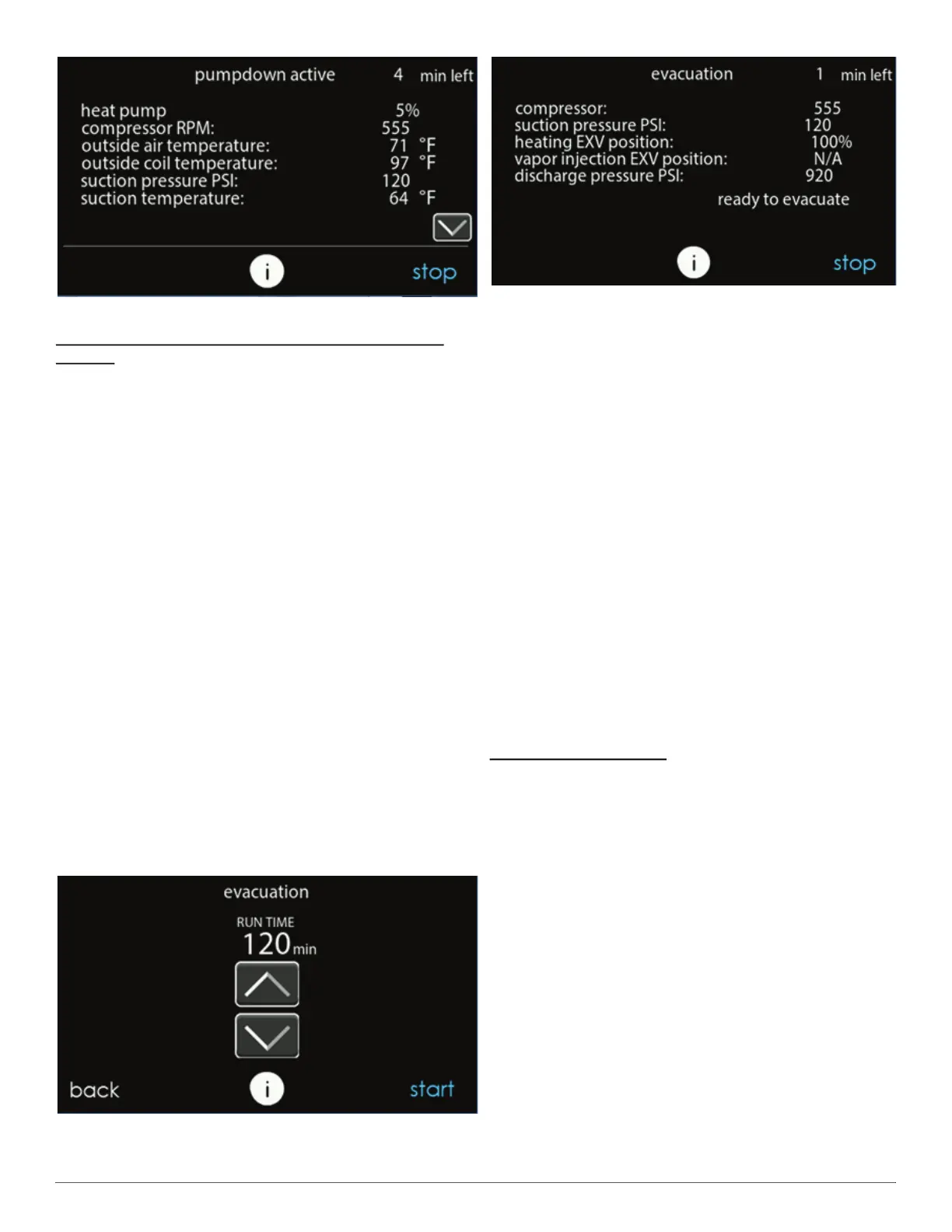

Fig. 22 – Pump Down Status Screen

Evacuation and Recovery of Refrigerant from within

186CNV

Because the 5 ton unit has an EXV for the vapor injection device,

additional steps must be taken to open the EXV if the OD unit must be

evacuated for service reasons. If the EXV is not open when pulling a

vacuum or recovering refrigerant from the OD unit, extended evacuation

time may be required and/or inadequate vacuum obtained. The UI (User

Interface) has provisions to open the EXV for refrigerant recovery

and/or evacuation.

1. Connect gages to liquid and vapor or suction capillary service ports

to monitor operating pressures during and at completion of the

procedure. Attach recovery system or vacuum pump to gage set as

needed for the service procedure. The service valves must be open

to evacuate the unit through the line set service ports. The suction

capillary service port is a direct connection to the suction port of the

compressor.

2. In the "installation and service" menu of the UI (see Fig. 10), go to

"refrigerant charging" and then "evacuation" (see Fig. 11) and

Fig. 12).

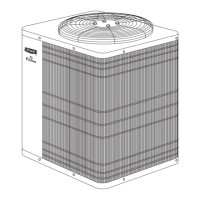

3. Set desired time period. Default time period for the procedure is

120 minutes. See Fig. 23.

4. Select START on UI to open the valve.

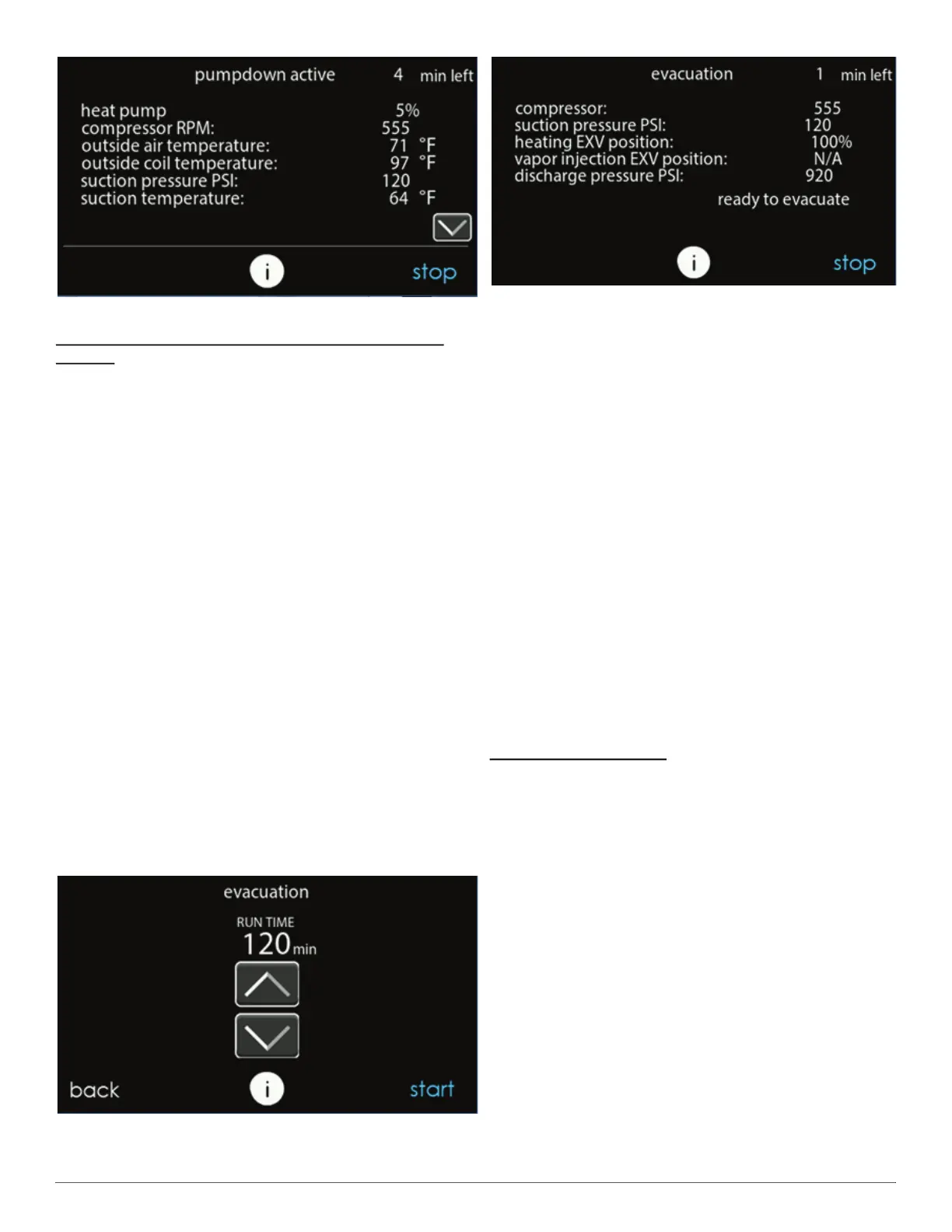

5. Begin evacuation or refrigerant recovery as required for the

procedure after UI indicates the EXV is open. Power may be

removed from outdoor unit after the UI indicates "READY TO

EVACUATE." See Fig. 24.

6. Remove power from indoor and outdoor unit prior to servicing unit.

The EXV will retain the open position.

NOTE: See service training materials for troubleshooting the EXV

using EXV CHECK mode.

A200042

Fig. 23 – Evacuation Setup Screen

A200043

Fig. 24 – Evacuation Status Screen

Step 13 – System Functions and Major Components

The 186CNV models utilize an Evolution Communicating User

Interface (UI). When a demand for cooling exists, the wall control will

direct the outdoor unit to operate at the minimum required speed to

satisfy demand. With a call for cooling, the outdoor fan is energized

followed by the compressor to run at a start speed. Once the start criteria

is met the compressor and fan will ramp to the target demand. If

continued operation at the initial speed does not satisfy demand, the

system will ramp up in 60 RPM increments until it satisfies the demand.

After coping with the higher demand, the unit returns to lower capacity

operation until the demand is satisfied or until an increase in demand

occurs. Ideal performance is achieved when system operates

continuously at the lowest speed possible, minimizing variation in

conditioned space temperatures while using minimal power.

As the unit operates at lower capacity, system vapor (suction) pressure

will be higher than it is during a standard single-stage system operation

or during a higher capacity operation.

When all demand is satisfied, the compressor will shut off. An internal

pressure equalization valve will energize during the off-cycle to allow

for easy start up at the next call for cooling.

The user interface (UI) displays the operation mode and fault codes as

specified in the troubleshooting section. See Table 7 for codes and

definitions.

NOTE: Only one code will be displayed on the outdoor unit control

board (the most recent, with the highest priority). The latest codes are

stored and can be accessed via the UI.

Primary Control Module

The Primary Control Module (PCM) controls the various functions of

the outdoor unit. The PCM has the following outputs:

1. Vapor Injection EXV

2. VFD Modbus communication

3. VFD low-voltage relay control

4. Pressure Equalization valve

5. O signal

6. W signal

7. Liquid Line Solenoid

The PCM has the following inputs:

1. Outdoor discharge thermistor (ODT)

2. Outdoor ambient thermistor (OAT)

3. Outdoor coil thermistor (OCT)

4. Discharge & suction pressure transducers (OPT)

5. Service Interface communication port

6. CCN communication (ABCD plug)

7. Model plug

8. 24VAC input power

The PCM receives a cooling demand from the wall control and

determines the appropriate compressor, fan, PEV, and LLS action based

upon the various sensor inputs.

Loading...

Loading...