186CNV: Installation Instructions

Manufacturer reserves the right to change, at any time, specifications and designs without notice and without obligations.

4

Step 5 – Elevate Unit

Elevate unit per local climate and code requirements to provide

clearance above estimated snowfall level and ensure adequate drainage

of unit.

Step 6 – In Long-Line Applications, Install Liquid-Line

Solenoid Valve (LSV)

For refrigerant piping arrangements with equivalent lengths of greater

than 80 ft. (24.38 m) and/or when elevation difference between indoor

and outdoor unit is greater than ±20 ft. (±6.10 m), follow the piping

configuration and liquid line solenoid valve (LSV) accessory

requirements from the Residential Piping and Long-line guideline. CCH,

start gear and piston changes do not apply. If required by Long-Line

Guideline, install LSV kit, part no. KHALS0401LLS. LSV should be

installed within 2 ft. (0.61 m) of outdoor unit with flow arrow pointing

toward outdoor unit.

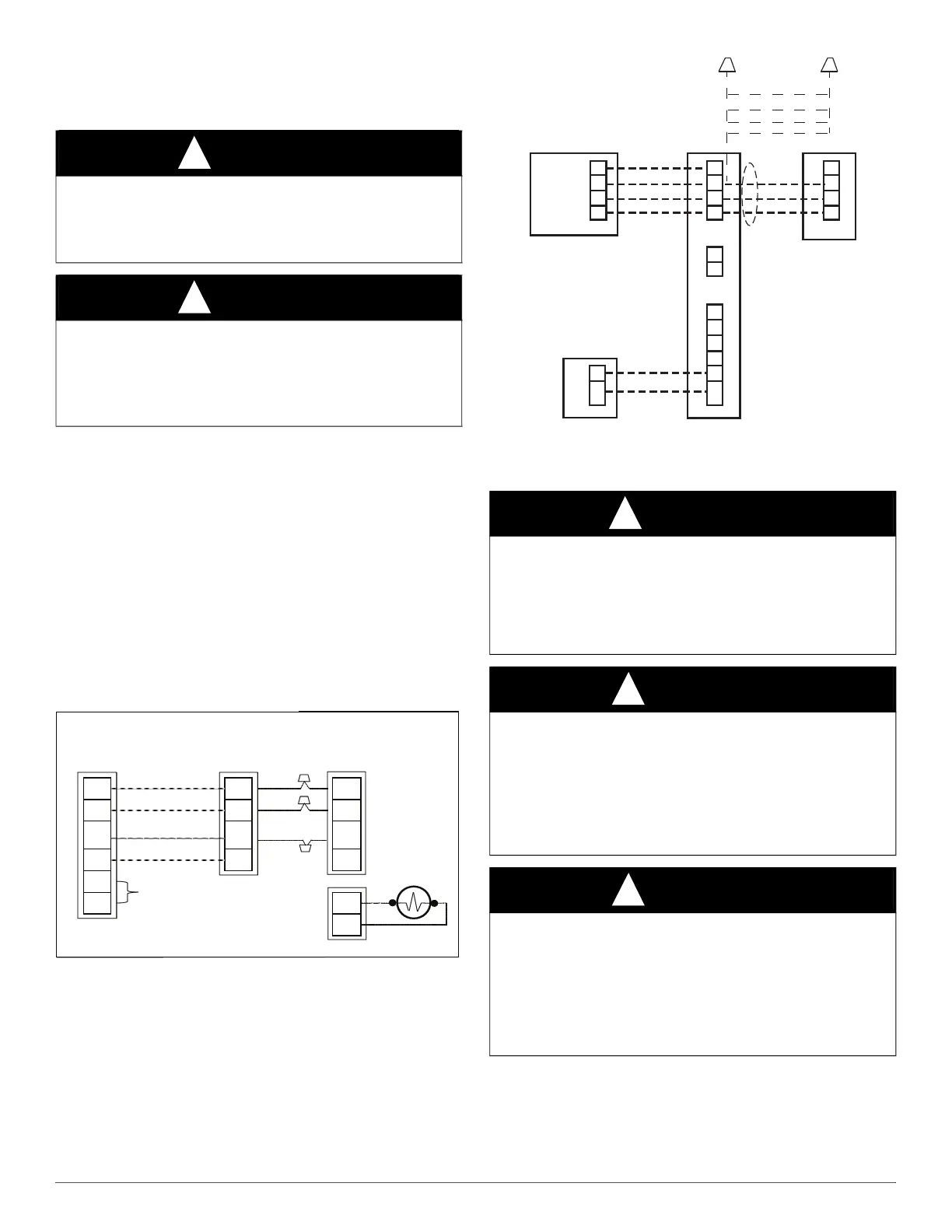

Make the necessary electrical connections as shown in Fig. 3 and Fig. 4

and by following the Installation Instructions included with accessory

kit.

IMPORTANT: Flow arrow must point toward outdoor unit.

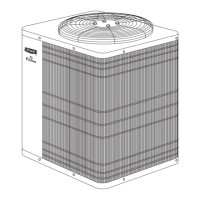

A180243

Fig. 3 – Liquid Line Solenoid Electrical Connection

(Required for long line applications)

A200204

Fig. 4 – Evolution Furnace or Fan Coil Wiring with Communicating

Variable Speed AC

Step 7 – Make Piping Connections

Outdoor units may be connected to indoor section using accessory

tubing package or field-supplied refrigerant grade tubing of correct size

and condition. For tubing requirements beyond 80 ft. (24.38 m),

substantial capacity and performance losses can occur. Follow the pipe

sizing recommendations in the 186CNV Product data to manage these

losses.

CAUTION

!

UNIT OPERATION HAZARD

Failure to follow this caution may result in equipment damage or

improper operation.

Do not allow water and/or ice to build up in base pan.

CAUTION

!

UNIT OPERATION HAZARD

Failure to follow this caution may result in equipment damage or

improper operation.

Locate the unit in such a way that it is stable in all circumstances

including adverse weather conditions.

Furnace or

Fan Coil

Variable Speed

AC or HP

WARNING

!

PERSONAL INJURY AND UNIT DAMAGE

HAZARD

Failure to follow this warning could result in personal injury or death.

Relieve pressure and recover all refrigerant before system repair or

final unit disposal. Use all service ports and open all flow-control

devices, including solenoid valves.

CAUTION

!

UNIT DAMAGE HAZARD

Failure to follow this caution may result in equipment damage or

improper operation.

Do not leave system open to atmosphere any longer than minimum

required for installation. PVE oil in compressor is extremely

susceptible to moisture absorption. Always keep ends of tubing sealed

during installation.

CAUTION

!

UNIT DAMAGE HAZARD

Failure to follow this caution may result in equipment damage or

improper operation.

If ANY refrigerant tubing is buried, provide a 6 in. (152.4 mm) vertical

rise at service valve. Refrigerant tubing lengths up to 36 in. (914.4 mm)

may be buried without further special consideration. Do not bury lines

longer than 36 in. (914.4 mm).

D

C

B

A

Wall Control

HP or AC

OAT

RYOWCHUM

C

Humidifier

24vac

Furnace or Fan Coil

’C’ connection optional

D not required

C

B

A

D

C

B

A

Loading...

Loading...