Residential Air Conditioners and Heat Pumps Using R-22 and Puron® Refrigerant: Application Guideline and Service Manual

Manufacturer reserves the right to change, at any time, specifications and designs without notice and without obligations.

34

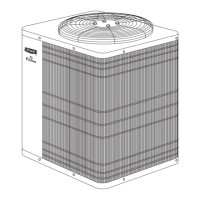

Aluminum Coil Removal

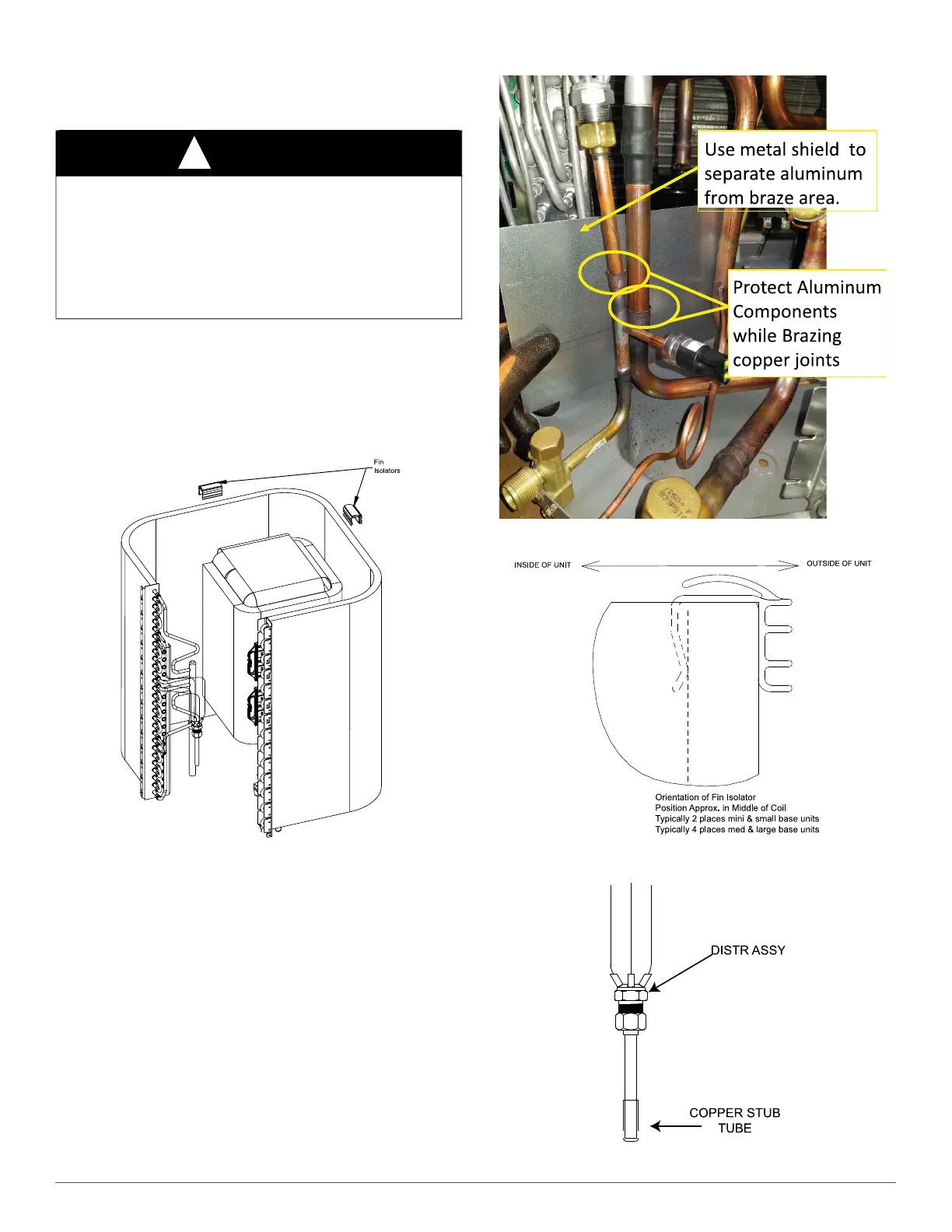

For all aluminum coils, the coil has two or four (depending on size of

unit) fin isolators on the top of the coil as shown in Fig. 31. These must

be reinstalled onto replacement coil.

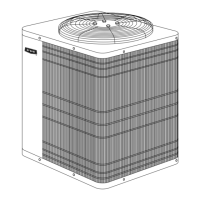

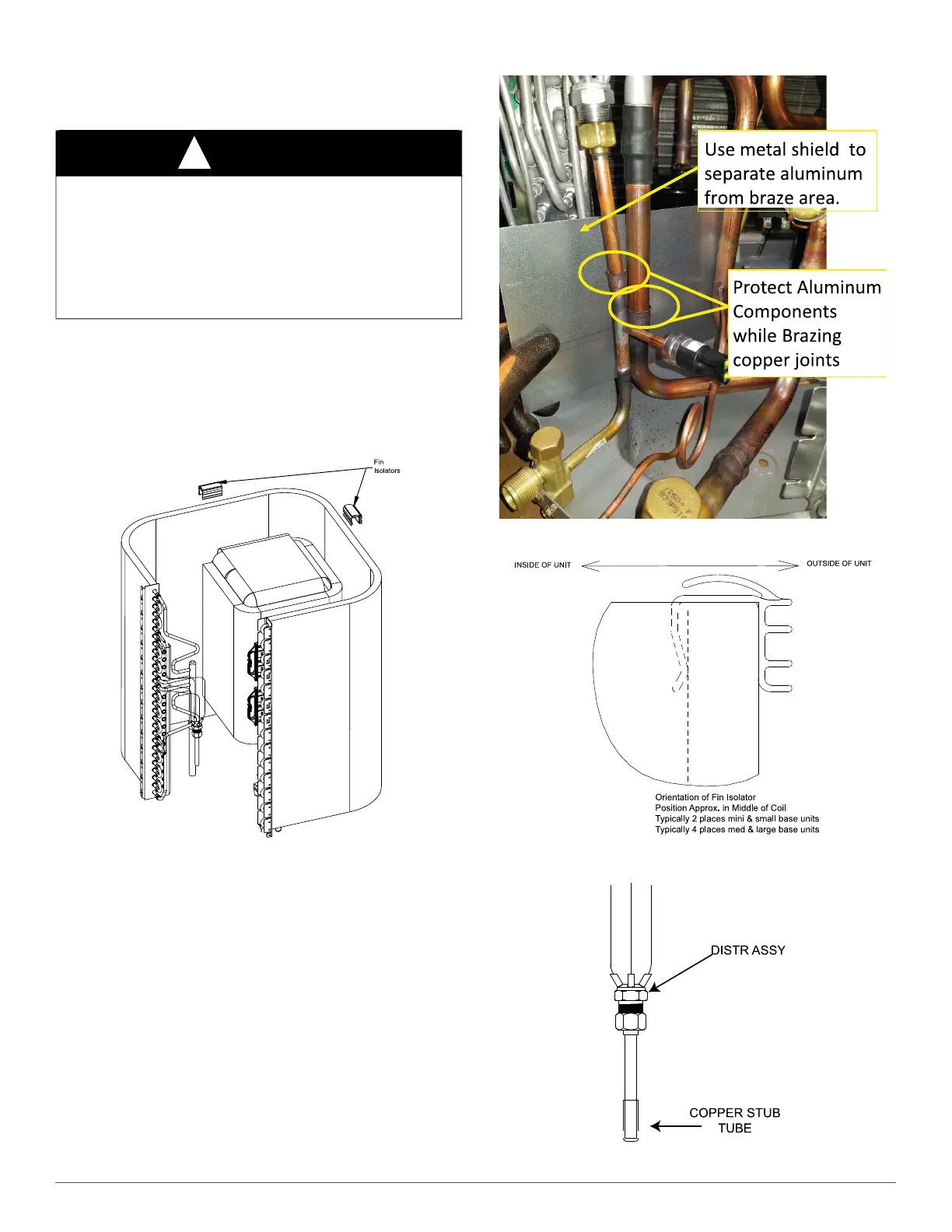

Fabricate a metal braze shield of approximately 8” X 8” to protect

aluminum components when brazing (see Fig. 32).

The orientation of the fin isolator is shown in Fig. 33. There is a threaded

mechanical fitting on the liquid distributor. This connection is not field

serviceable and should not be disturbed.

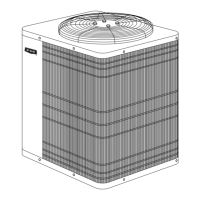

The copper stub tube connection to the liquid service valve needs to be

un-brazed for coil removal. (See Fig. 34.)

A13187A

Fig. 31 – Fin Isolator Location

A190396

Fig. 32 – Use Braze Shield to Protect Aluminum

A13186A

Fig. 33 – Fin Isolator Orientation

A13188

Fig. 34 – Copper Stub Tube Connection

CAUTION

!

UNIT DAMAGE HAZARD

Failure to follow this caution may result in premature corrosion failure

of aluminum coil

During coil replacement, when brazing the new coil into the unit, a

guard is needed so copper-to-copper joint braze splatter does not reach

any aluminum parts. This can cause pitting and premature failure due

to corrosion.

Loading...

Loading...