13

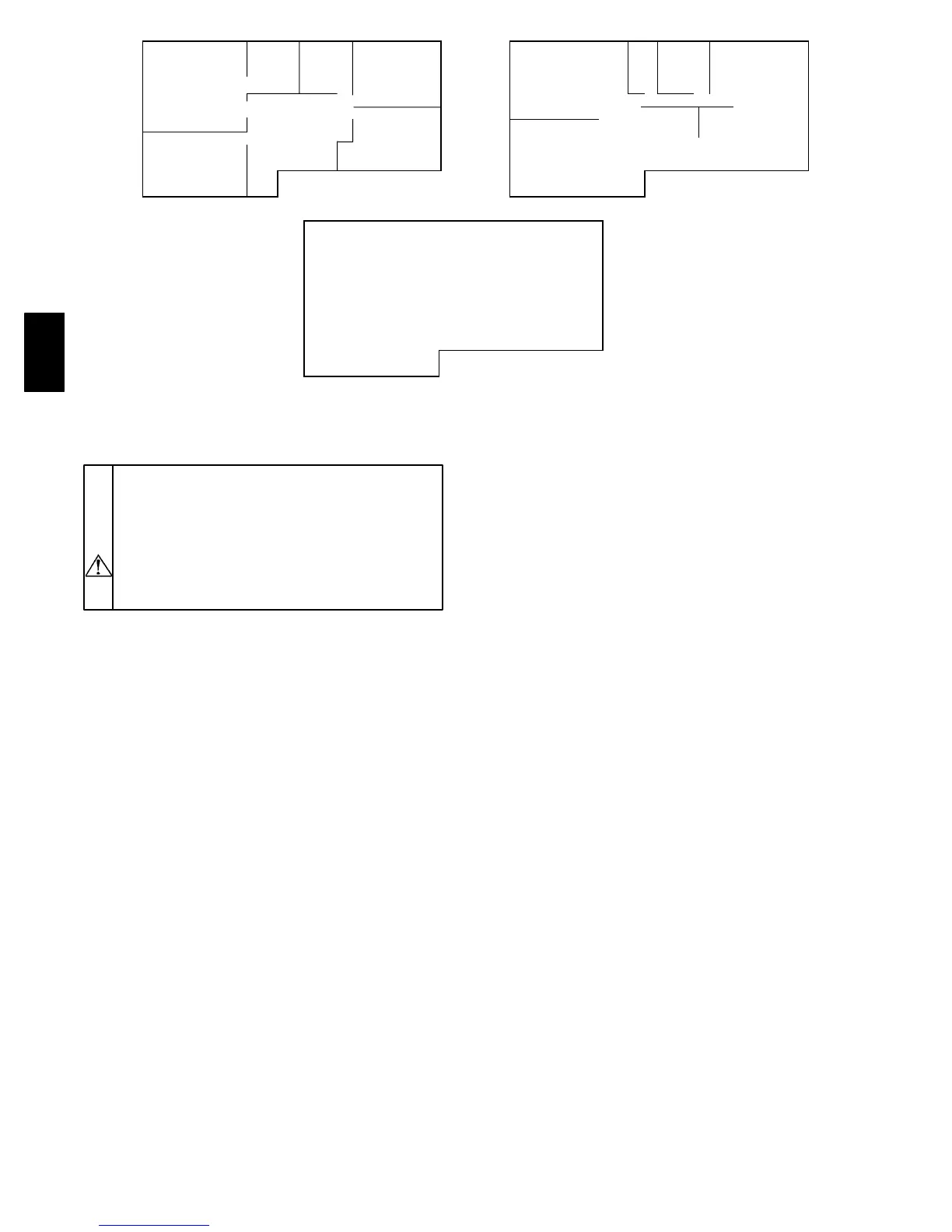

BASEMENT

MASTER

BEDROOM

WASH-

ROOM

#1

WASH-

ROOM

#2

BEDROOM

#3

BEDROOM

#5

BEDROOM

#4

1320 sq ft

(125 sq m) 1320 sq ft

(125 sq m)

LIVING ROOM

#6

FAMILY ROOM

#10

KITCHEN

#9

LAUNDARY

ROOM

#8

WASH-

ROOM

#7

DINING ROOM

#11

1320 sq ft

(125 sq m)

A98388

Fig. 25 --- Floor Plan Example

VENTILATION EV ALUATION

CAUTION: UNIT DAMAGE HAZARD

Failure to follow this caution may result in reduced

unit efficiency, capacity or unit life.

DO NOT use HRV during construction of a house

or when sanding drywall. This type of dust may

damage system.

When ventilation requirement is determined, use Product

Data Sheets to reference unit airflow delivery and

performance.

The ventilation capacity of an HRV unit while at maximum

speed is defined according to greatest total airflow

required. These methods are derived from the Canadian

National Building Code 1995 version and the CSA F326.1

revision.

The following 2 methods can be used to evaluate the

approximate ventilation needs of a house. Accuracy of

calculations are dependent upon the information available

and knowing critical measurements of the structure (See

Fig. 25).

METHOD 1

To calculate approximate ventilati on:

The sum of rooms X 10 CFM per room, plus 20 CFM for

a master bedroom or basement.

Example: 11 rooms X 10 CFM + 2 X 20 CFM = 150 CFM.

Note: The master bedroom and basement are not included

in first part of this equation, but figured in at second part of

equation.

METHOD 2

To calculate approximate ventilati on:

Referencing same example (See Fig. 25).

Total cu ft X 0.3 per hr = total. Take total and divide by

60 to get CFM.

Example:

1320 sq ft X 8 ft in height = 10560 cu ft per floor

10560 cu ft x 3 floors = 31680 total cu ft in house

31680 cu ft X 0.3 air change per hr = 9500 cu ft

9500 cu ft ÷ 60 minimum per hr = 160 CFM.

Conclusion: The total amount of air flow needed is 160

CFM. This falls within airflow range of a HRVBBLHA1150

size unit.

CONTROL BOARD OPERATION

Step 1.—Board Function

Note: To ensure proper operation of HRV, configuration

jumpers are located on electronic control board and must

match configuration setup shown on Fig. 26 and 27. under

Jumper Table.

Jumpers are factor y set and do not require any changes

unless control board is replaced. If control board is

replaced, or you encounter unusual start---up operation,

check jumpers to make sure they are located properly (See

Fig. 26 and 27).

Step 2.—Defrost

The HRV continually monitors the outside air temperature.

Iftheoutsideairisatorbelow23°F ( --- 5 °C), the HRV will

initiate a defrost cycle by closing the outside air damper

and recirculating warm indoor air through the heat recovery

core. This happens every 32 min. with 6 m inute defrost

cycle. During this process, core is defrosted without the use

of electric strip heat. At 5°F ( --- 1 5 °C), unit will defrost for 6

minutes every 32 min. At ---17°F ( --- 2 7 °C), the unit will sense

a need to defrost every 20 minutes with a 6 minute cycle.

See the Troubleshooting section for a control logic

explanation.

Step 3.—Off and Intermittent/Off Mode

When HRV is Off, K1 relay is open, and K5 relay is

energized which closes outside air damper (See Logic

Diagram in Fig. 26 and 27).

Step 4.—High ---Speed Air Exchange

When high---speed air exchange occurs, K1 and K2 relays

are energized and K5 relay is de---energized. This opens

low---speed contacts, and closes high---speed contact on

K2 relay . This also opens contact on K5 relay which opens

outside air damper. Then, 115vac is applied between

orange and gray wires on Molex plug (pins 1 and 6) and

blower motor runs in high---speed operation. (See Logic

Diagram in Fig. 26 and 27).

HRV

Loading...

Loading...