12

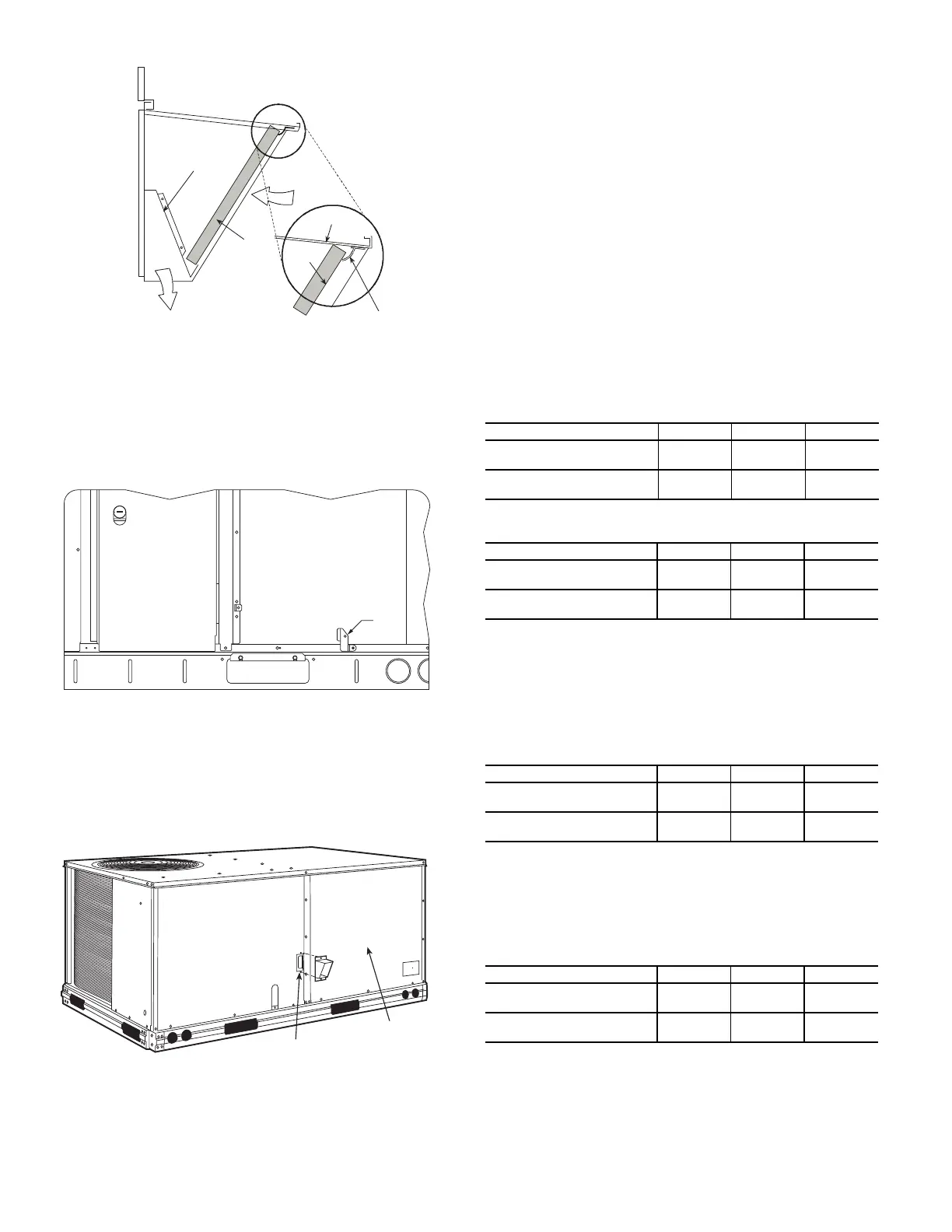

Fig. 14 — Economizer Filter Installation

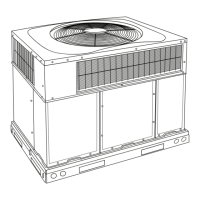

Step 9 — Units with Hinged Panels Only

Relocate latch shipped inside the compressor compartment behind

the hinged compressor door to location shown in Fig. 15 after unit

installation.

If the unit does not have hinged panels, skip this step and continue

at Step 10.

Fig. 15 — Compressor Door Latch Location

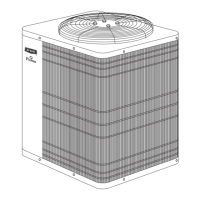

Step 10 — Install Flue Hood

Flue hood is shipped screwed to the basepan beside the burner

compartment access panel. Remove from shipping location and

using screws provided, install flue hood and screen in location

shown in Fig. 16.

Fig. 16 — Flue Hood Details

Step 11 — Install Gas Piping

Installation of the gas piping must be accordance with local build-

ing codes and with applicable national codes. In U.S.A., refer to

NFPA 54/ANSI Z223.1 National Fuel Gas Code (NFGC). In

Canada, installation must be accordance with the CAN/CSA

B149.1 and CAN/CSA B149.2 installation codes for gas burning

appliances.

This unit is factory equipped for use with Natural Gas fuel at ele-

vations up to 2000 ft (610 m) above sea level. Unit may be field

converted for operation at elevations above 2000 ft (610 m) and/or

for use with liquefied petroleum fuel. See accessory kit installation

instructions regarding these accessories.

NOTE: Furnace gas input rate on rating plate is for installation up

to 2000 ft (610 m) above sea level. The input rating for altitudes

above 2000 ft (610 m) must be derated by 4% for each 1000 ft

(305 m) above sea level.

For natural gas applications, gas pressure at unit gas connection

must not be less than 4 in. wg (996 Pa) or greater than 13 in. wg

(3240 Pa) while the unit is operating. On 582JF*05-06 (high-heat)

units, the gas pressure at unit gas connection must not be less than

5 in. wg (1245 Pa) or greater than 13 in. wg (3240 Pa) while the

unit is operating, see Table 3. For liquified petroleum applications,

the gas pressure must not be less than 11 in. wg (2740 Pa) or great-

er than 13.0 in. wg (3240 Pa) at the unit connection, see Table 4.

The gas supply pipe enters the unit at the burner access panel on

the front side of the unit, through the long slot at the bottom of the

access panel. The gas connection to the unit is made to the

1

/

2

-in.

FPT gas inlet port on the unit gas valve.

Manifold pressure is factory-adjusted for natural gas fuel use. Ad-

just as required to obtain best flame characteristics. See Table 5.

Manifold pressure for LP fuel use must be adjusted to specified

range. Follow instructions in the accessory kit to make initial read-

justment, see Table 6.

DIVIDER

BAROMETRIC

RELIEF

CLEANABLE

ALUMINUM

FILTER

FILTER

HOOD

FILTER

CLIP

OUTSIDE

AIR

COMPRESSOR DOOR

OUTDOOR COIL

LATCH

BLOWER

ACCESS

PANEL

FLUE OPENING

Table 3 — Natural Gas Supply Line Pressure Ranges

UNIT MODEL UNIT SIZE MIN. MAX.

582JD/E/L/M/S/R 04, 05, 06

4.0 in. wg

(996 Pa)

13.0 in. wg

(3240 Pa)

582JF/N/T

(High Heat Units Only)

05, 06

5.0 in. wg

(1245 Pa)

13.0 in. wg

(3240 Pa)

Table 4 — Liquid Propane Supply Line Pressure Ranges

UNIT MODEL UNIT SIZE MIN. MAX.

582JD/E/S/R 04, 05, 06

11.0 in. wg

(2740 Pa)

13.0 in. wg

(3240 Pa)

582JF/T

(High Heat Units Only)

05, 06

11.0 in. wg

(2740 Pa)

13.0 in. wg

(3240 Pa)

Table 5 — Natural Gas Manifold Pressure Ranges

UNIT MODEL UNIT SIZE HIGH FIRE LOW FIRE

582JD/E/L/M/S/R 04, 05, 06

3.5 in. wg

(872 Pa)

SEE NOTE

BELOW

582JF/N/T

(High Heat Units Only)

05, 06

3.5 in. wg

(872 Pa)

SEE NOTE

BELOW

NOTE: LOW FIRE, 1.7 in. wg (423 Pa), applies to the following three

phase voltage units only: 582JE04 and 582JF05/06.

Table 6 — Liquid Propane Manifold Pressure Ranges

unit model UNIT SIZE high fire low fire

582JD/E/S/R 04, 05, 06

10 in. wg

(2490 Pa)

SEE NOTE

BELOW

582JF/T

(High Heat Units Only)

05, 06

10 in. wg

(2490 Pa)

SEE NOTE

BELOW

NOTE: LOW FIRE, 5.0 in. wg (1245 Pa), applies to the following three

phase voltage units only: 582JE04 and 582JF05/06.

Loading...

Loading...