7 Systems

6 720 646 864 (12/2010) – Technical guide Logano GE315, GE515 and GE615

48

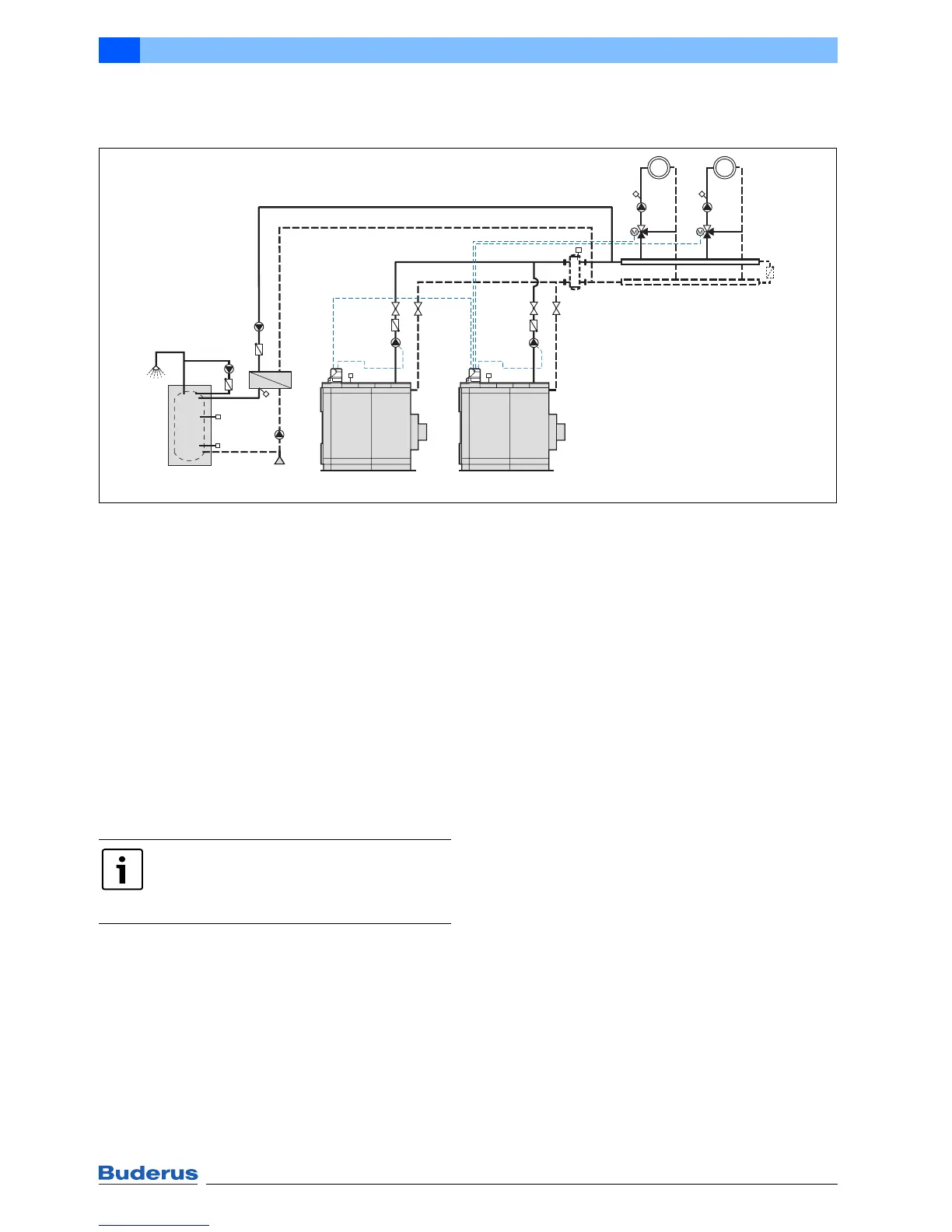

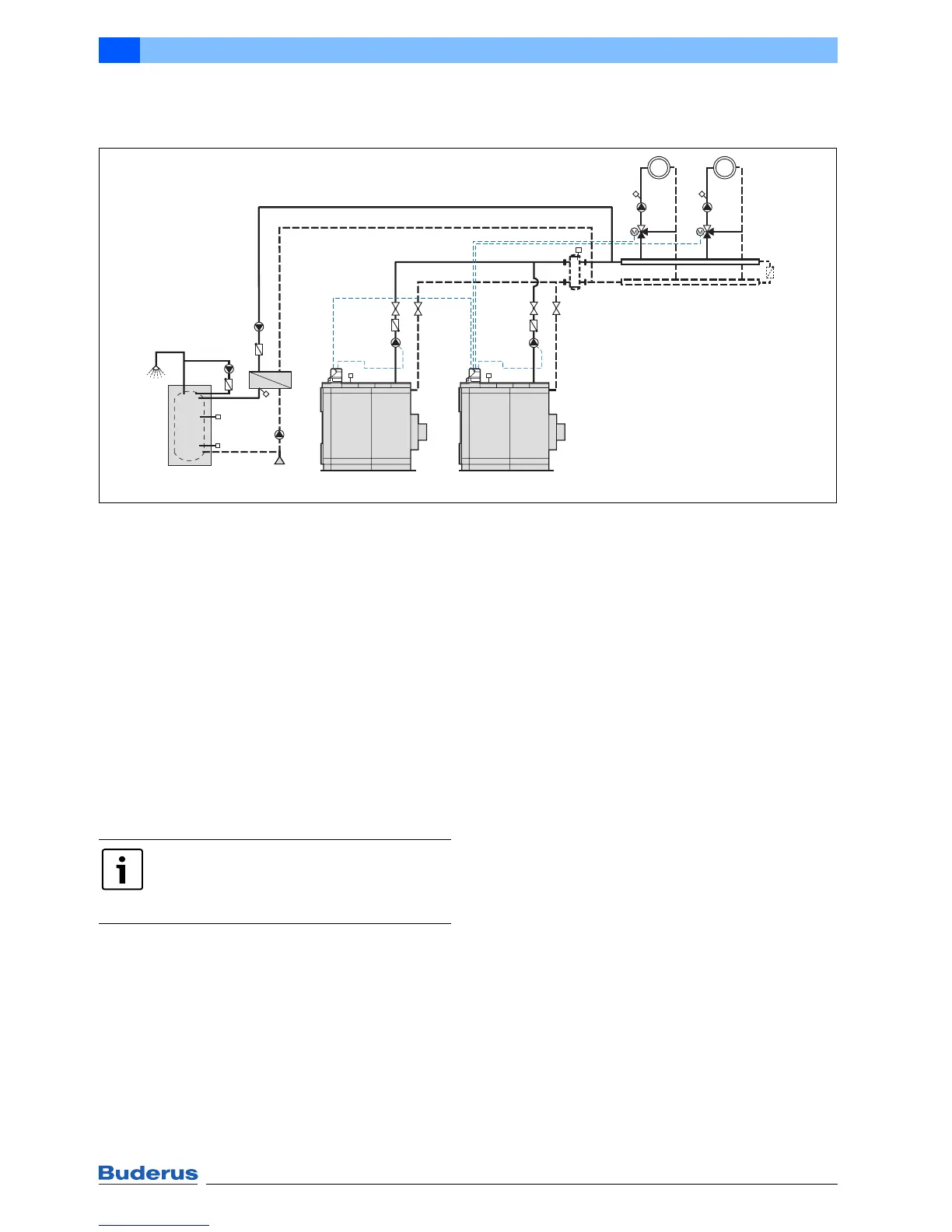

7.7 2-boiler system with boiler control and heating circuit control, plus hydraulic

balancing

Fig. 37 System example for two Ecostream cast iron boilers; DHW heating with primary store system; number and

version of the heating circuits dependent on the Logamatic control unit

EK Cold water inlet

FK Boiler water temperature sensor

FV Flow temperature sensor

FVS Strategy flow temperature sensor

FW DHW temperature sensor

HK Heating circuit

KR Check valve

PH Heating circuit pump

PK Feed pump

PS Primary circuit pump

PW Stratification pump

PZ DHW circulation pump

RK Return

SH Heating circuit actuator

VK Boiler flow

WT Heat exchanger

1 Primary store system (DHW cylinder as option)

Application area

• Ecostream cast iron boilers Logano GE315, GE515

and GE615

• Boiler control and heating circuit control (heating

circuits with actuators) with Logamatic 4211 or 4311

control unit

Function description

The boiler sequence can be controlled via the multi boiler

strategy module subject to load and time. If the

temperature at the strategy sensor FVS falls below the set

flow temperature, the Logano (1) lead boiler starts. The

lag boiler is hydraulically shut off via the check valve KR in

the boiler flow. If the heat demand increases, the Logano

(2) lag boiler is automatically switched on. If the load falls,

the switching processes run in reverse order.

The Logamatic control unit safeguards the operating flow

temperature of both boilers. If the operating flow

temperature at temperature sensor FK1 or FK2 falls

below the set value when the burner is on, the control unit

reduces the flow rate in the flow by overriding control of

the heating circuit actuators SH until the operating

temperature has been reached.

Special engineering information

• In conjunction with hydraulic balancing, the feed

pumps PK are advisable if there are several distributor

stations, or if these are far apart. A low loss header or

low-pressure distributor with bypass and check valve

can be used for hydraulic balancing.

• A low loss header is also suitable for de-sludging.

• Distribute the total output between the boilers so each

has 50 %. If the output is distributed differently,

safeguard the flow rates using suitable measures

(sizing the pipework and/or pumps).

HK2HK1

SH2

PH2

SH1

PH1

VK

RK

FV1

FV2

FK2

VK

RK

FK1

FVS

KR

KR

PS

PW

FW2

KR

PZ

FW3

FW1

EK

WT

KR

PK2

KR

PK1

6 720 644 097-31.1il

Logano (2) Logano (1) 1

The circuit diagram is only a schematic

illustration!

For information on all system examples,

Æ page 36.

Loading...

Loading...