8

Operating instructions Oil- and gas-fired special boilers Logano GE515 • Issue 2018/01

We reserve the right to make any changes due to technical modifications.

Using correct fill and make-up water3

3.2 Water quality

Any water contains substances, e. g. Ca (HCO

3

)

2

(Calcium hydrogen-carbonate), which may influence the

function of your heating system. These may lead to

corrosion, scaling or deposits.

Regularly check your water quality and, if necessary,

treat your fill and make-up water, to ensure that your

heating system permanently retains its economy,

function, operational reliability and energy efficiency.

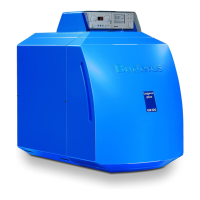

Observe the following table regarding the appropriate

use and treatment of the fill and make-up water.

This table is an extract from the Code of Practice K8

"Water treatment for hot water heating systems" in the

Buderus sales catalogue.

CAUTION!

SYSTEM DAMAGE

through corrosion and scaling because of

fill and make-up water, which does not

comply with system-specific requirements.

Check with your local heating

contractor or your water supply

company regarding the Ca (HCO

3

)

2

concentration (calcium hydrogen-

carbonate) in your area.

You should treat the fill and make-up

water, if it does not comply with system-

specific requirements. In such cases

contact your local heating engineer.

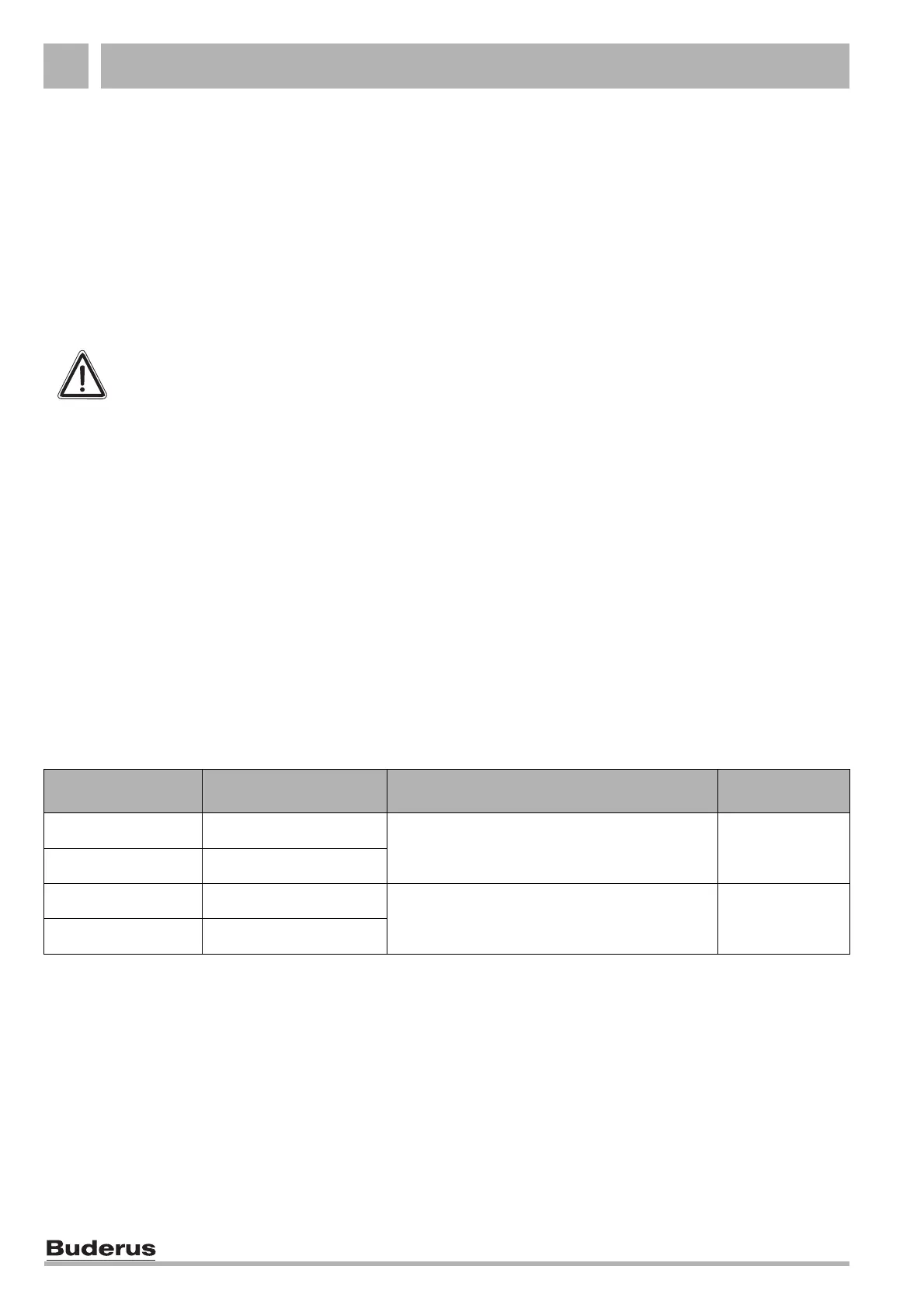

Total rated boiler

output in kW

Ca (HCO

3

)

2

concentration

in mol/m³

Maximum fill and make-up water

volume V

max

in m³

Heating water pH

value

100 < Q 350 2.0

V

max

= three times the system volume 8.2–9.5

350 < Q 1000 1.5

100 < Q 350 > 2.0

8.2–9.5

350 < Q 1000 > 1.5

Tab. 1 Requirements of filling, make-up and heating water

V

max

0 0313

QkW

Ca HCO

3

2

mol

m

3

----------

-------------------------------------------------

,=

Loading...

Loading...