32

Table 6: Maximum Capacity of Schedule 40 Pipe in CFH for Gas Pressures of 0.5 psig or Less

Table 7: Equivalent Lengths of Standard Pipe Fittings & Valves

Table 8: Specific Gravity Correction Factors

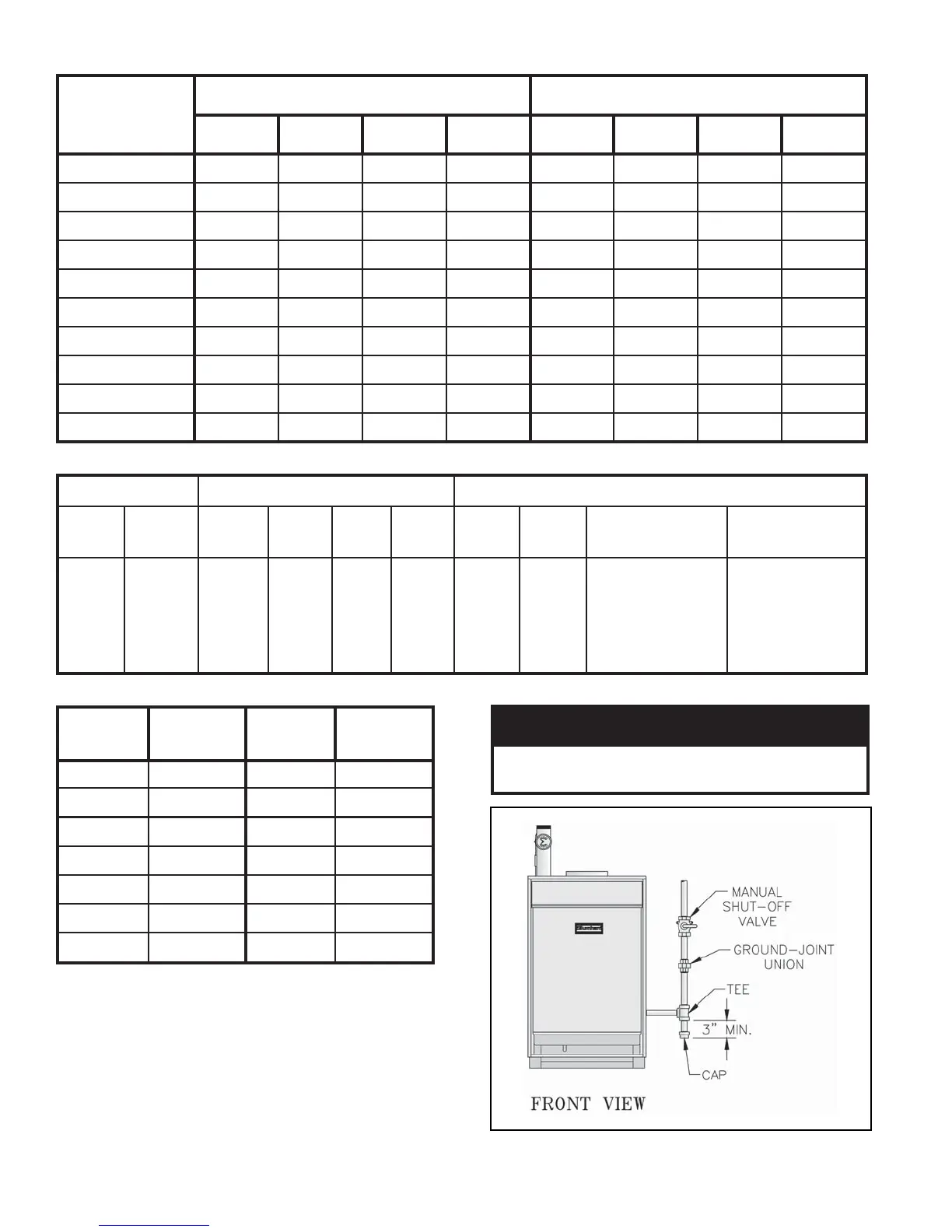

Figure 26: Recommended Gas Piping

C. Pressure Test. The boiler and its gas connection must

be leak tested before placing boiler in operation.

1. Protect boiler gas valve. For all testing over ½ psig,

boiler and its individual shut-off valve must be

disconnected from gas supply piping. For testing at

½ psig or less, isolate boiler from gas supply piping

by closing boiler's individual manual shut-off valve.

2. Locate leaks using approved combustible gas

detector, soap and water, or similar nonflammable

solution.

cificepS

ytivarG

noitcerroC

rotcaF

cificepS

ytivarG

noitcerroC

rotcaF

05.001.103.170.1

55.040.104.140.1

06.000.105.100.1

56.069.006.179.0

07.039.007.149.0

57.009.0

08.078.0

htgneL

]teeF[

porDerusserP.c.whcni3.0porDerusserP.c.whcni5.0

½¾ 1 ¼1½¾1¼1

01231872025050,1571063086004,1

0229091053037021052564059

033725158209579002573077

043603154200528071023066

056551151204437151582085

060550159100466831062035

07646908107316521042094

08340907105375811022064

09044806102335011502034

001839705150305301591004

)nepOylluF(sevlaVsgnittiFdedaerhT

epiP

eziS

.D.I

sehcnIetaGebolGelgnA

gniwS

kcehC

°09

woblE

°54

woblE

wolF,eeT°09

nuRhguorhT

wolF,eeT°09

hcnarBhguorhT

"½226.053.06.813.93.46.187.00.11.3

"¾428.044.01.325.113.51.279.04.11.4

"1940.165.04.927.418.66.232.18.13.5

"¼1083.147.06.833.919.85.36.13.29.6

GNINRAW

,semalfnepo,seldnac,sehctamesutonoD

.ecruosnoitingirehtoro

Loading...

Loading...