Cambridge Engineering, Inc. 26 S-Series Technical Manual

IMPORTANT

A negative manifold static (blower only) will cause

the manifold pressure reading to be lower than the

nameplate manifold differential pressure.

IMPORTANT

The high limit may trip on warm days. If this oc-

curs turn the blower on to allow the high limit to

cool. Turn the blower and burner service switches

to the "OFF" position. Access high limit and manu-

ally reset. Close the unit access doors and turn the

blower and burner service switches to the "LOCAL"

position.

h. Turn the burner service switch to the “LOCAL”

position. After a delay for prepurge and igniter

warm-up, the burner will light. Allow 15 seconds

for the low fire start to time out.

i. Observe the manometer reading and compare to the

manifold pressure determined above in Step 6.g. If

the manifold pressure reading does not equal this

value, adjust the control regulator until the proper

manifold pressure is obtained.

j. Turn the blower and burner service switches to the

“OFF” position.

k. Reconnect the wire to terminal #3 on the amplifier.

l. When performing a start-up proceed to the next

step, otherwise perform Final Heater Preparation

(page 29).

7. MINIMUM FIRE ADJUSTMENT

PROCEDURE

The minimum fire setting is preset at the factory at

approximately 20°F rise. This minimum fire setting

is not critical in space heating applications where the

heater is cycled in response to the space temperature

sensed by an operating thermostat. In this case, the

heater should operate at the maximum discharge tem-

perature, far from the minimum fire setpoint.

IMPORTANT

If a temperature rise of less than 15°F is desired,

a DC microammeter is required to monitor flame

signal during the adjustment procedure. Ensure

the flame current remains steady and of sufficient

strength to maintain burner operation for both con-

sistent ignition at minimum fire and locking in the

flame safeguard relay. Do not allow the flame signal

to drop below 2.0 microamps DC.

a. Turn the blower service switch to the “LOCAL”

position and monitor the discharge temperature.

b. On EDL, EDR and EDSM applications, remove the

wire from terminal #8 on the amplifier. This will

cause the burner to light on low fire and then fall to

minimum fire.

c. Turn the burner service switch to the “LOCAL”

position. After a delay for prepurge and igniter

warm-up, the burner will light. Allow 15 seconds

for the low fire start to time out.

d. Monitor the discharge temperature and flame sig-

nal. Subtract the temperature from step "7a" above

to determine the temperature rise. If the minimum

fire does not require adjustment, proceed to step

"7h".

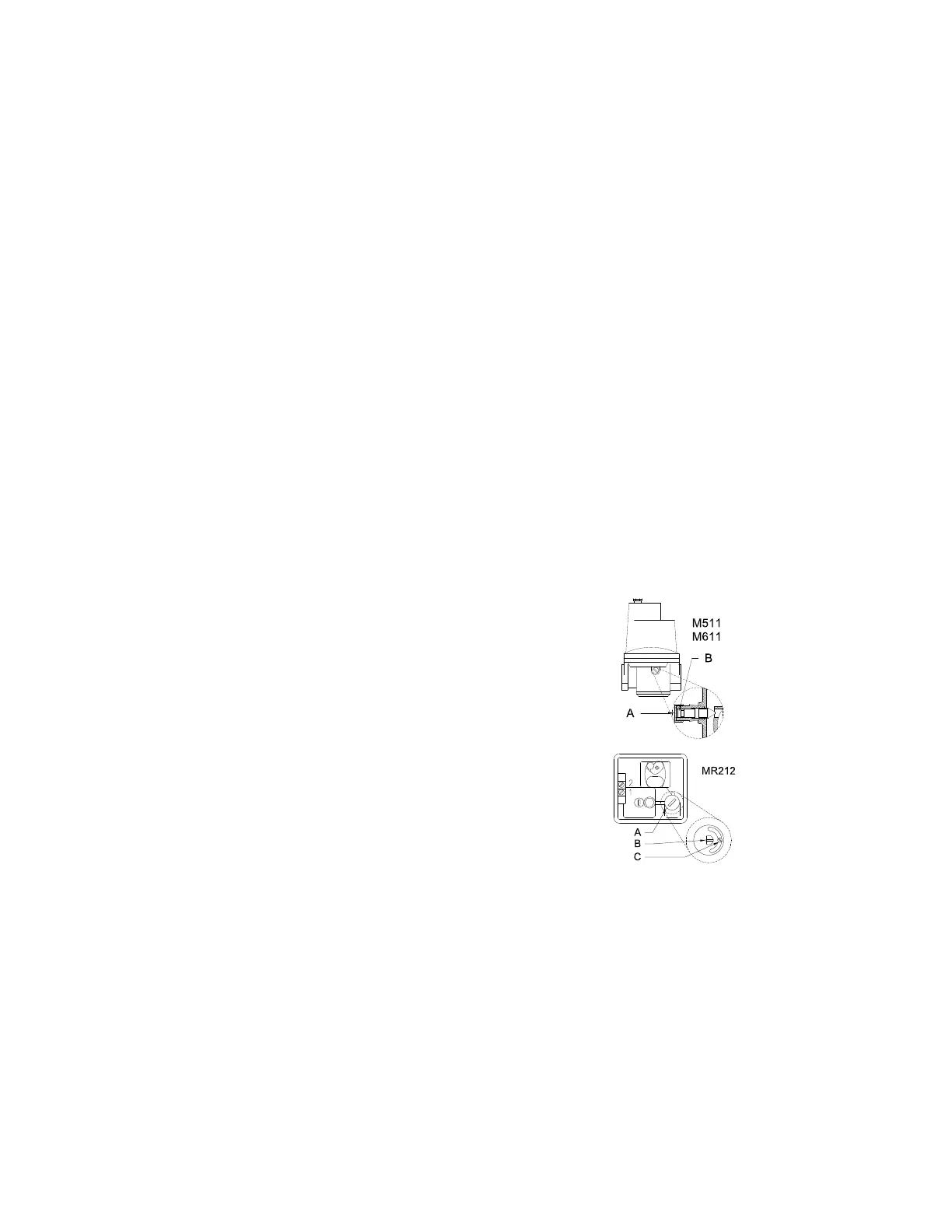

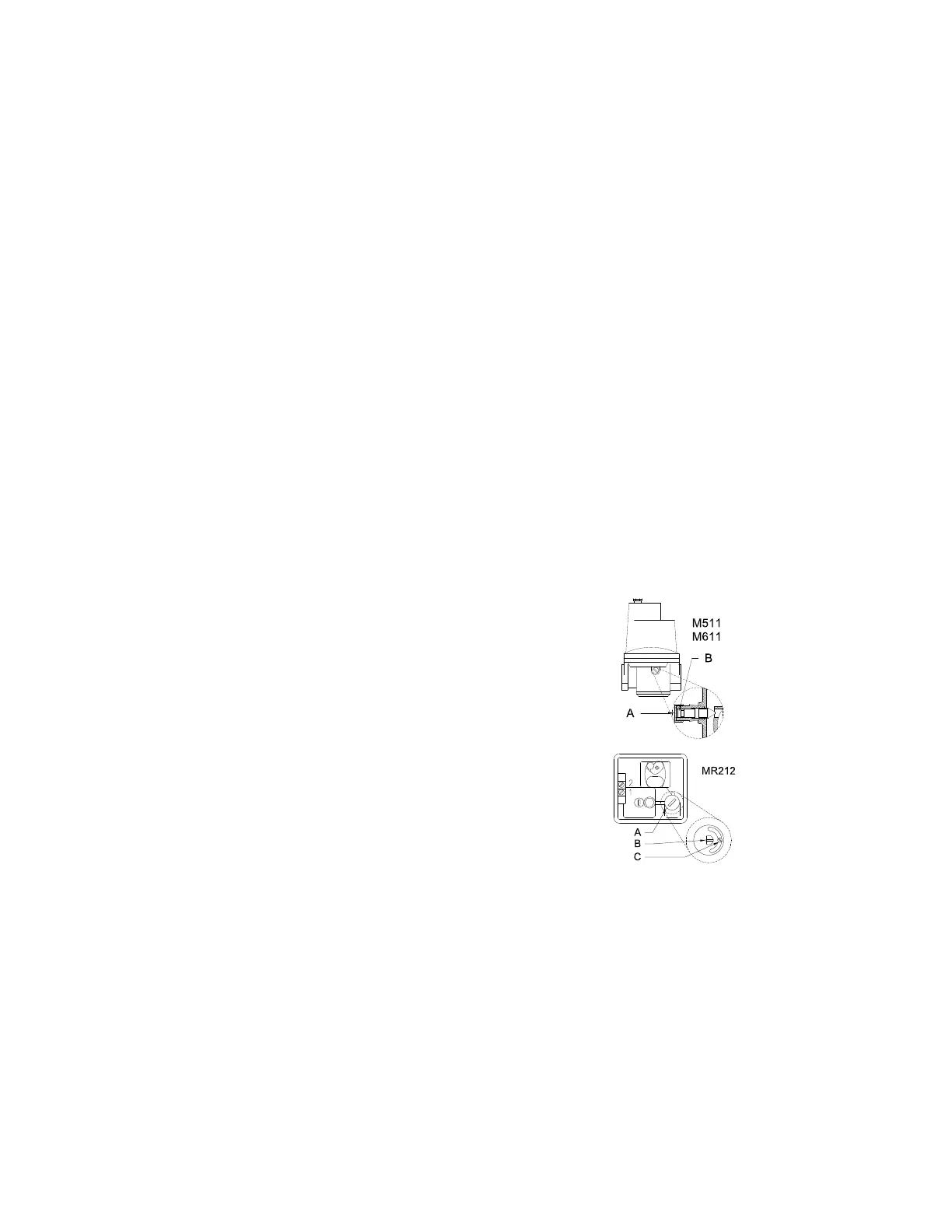

e. On the MR212 modulating/regulating valve,

remove the housing cover and loosen the lock

screw (C).

f. Remove the cap (A) exposing the minimum fire

adjusting screw. Turn the adjusting screw (B) to

obtain the desired minimum fire setting.

g. Replace the cap (A).

On the MR212 modulating/regulating valve,

tighten the lock screw (C) and replace the housing

cover.

h. Turn blower and burner service switches to the

“OFF” position.

i. Reconnect the wire to terminal #8 on the amplifier.

j. When performing a start-up proceed to the next

Loading...

Loading...