S-Series Technical Manual 31 Cambridge Engineering, Inc.

Take the RHA to the unit control enclosure. See

Individual Component Description (page 70) for

RHA details, and Heater Configuration (page 4) for

electrical control enclosure location.

4. Remove the wires from terminals 21 and 22 of the

right-hand side of Terminal Block #1 in the unit

control enclosure. Connect these wires to terminals

1 and 3 of the RHA.

5. Place a jumper between terminals 2 and 3 of the

RHA.

6. For the single dial RHA, the jumper activates the

0 to 40°F override dial. Verify the override tem-

perature selector dial is set to 40°. Verify the dial

on the face of the RHA is set to 90° to obtain a set-

point of 130°.

For the dual dial RHA, the jumper activates the

Space Heat selector dial. Verify the Space Heat dial

is set to 160°.

7. Turn the blower and burner service switches to the

“LOCAL” position. After a delay for the prepurge

and igniter warm-up, the burner will light.

8. Wait for the discharge temperature and manifold

pressure to stabilize. Do not rush this step. Allow

15 seconds for the low fire start to time out.

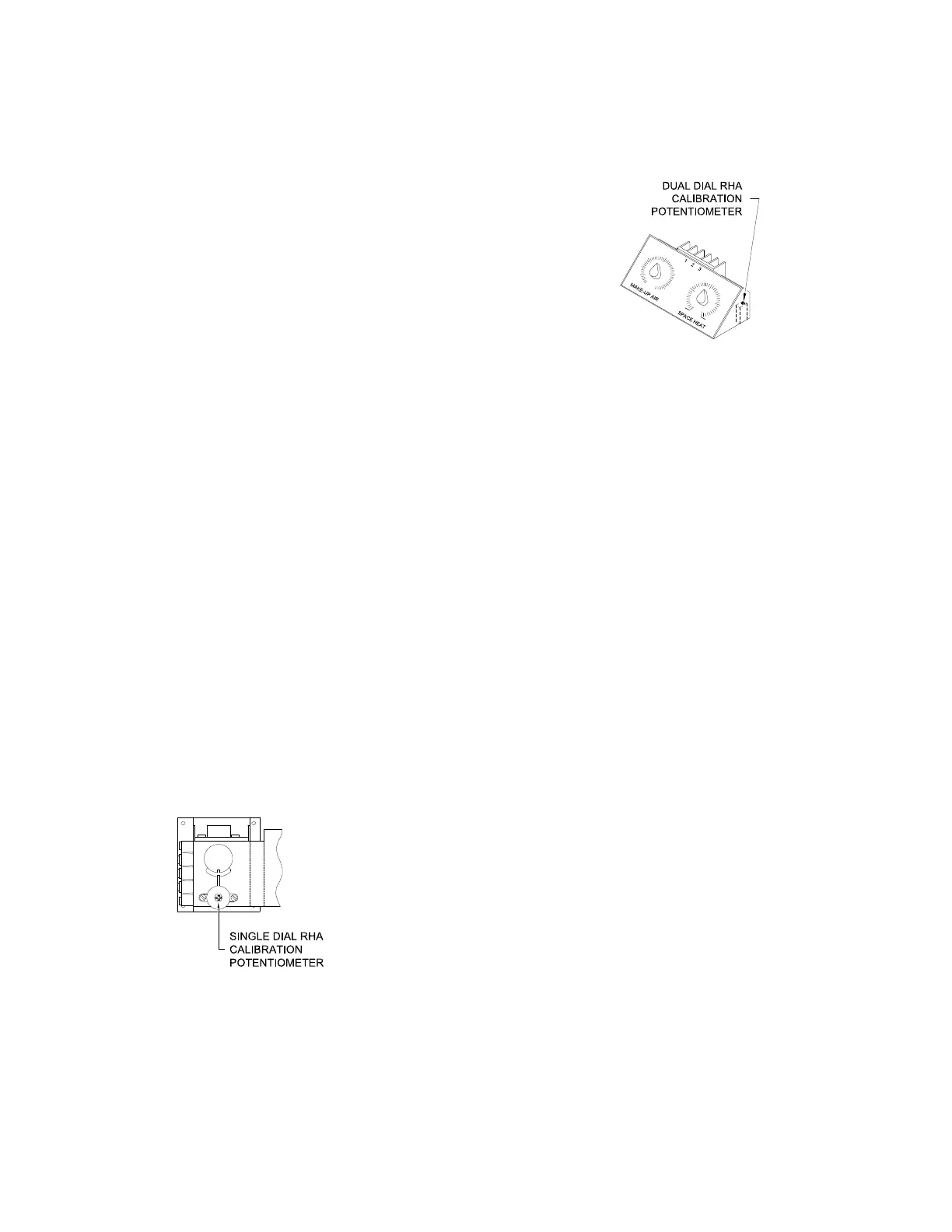

9. For the single dial RHA, adjust the calibration

potentiometer shown in the drawing. To raise the

discharge temperature, adjust the potentiometer

clockwise. To lower the discharge temperature,

adjust the potentiometer counterclockwise.

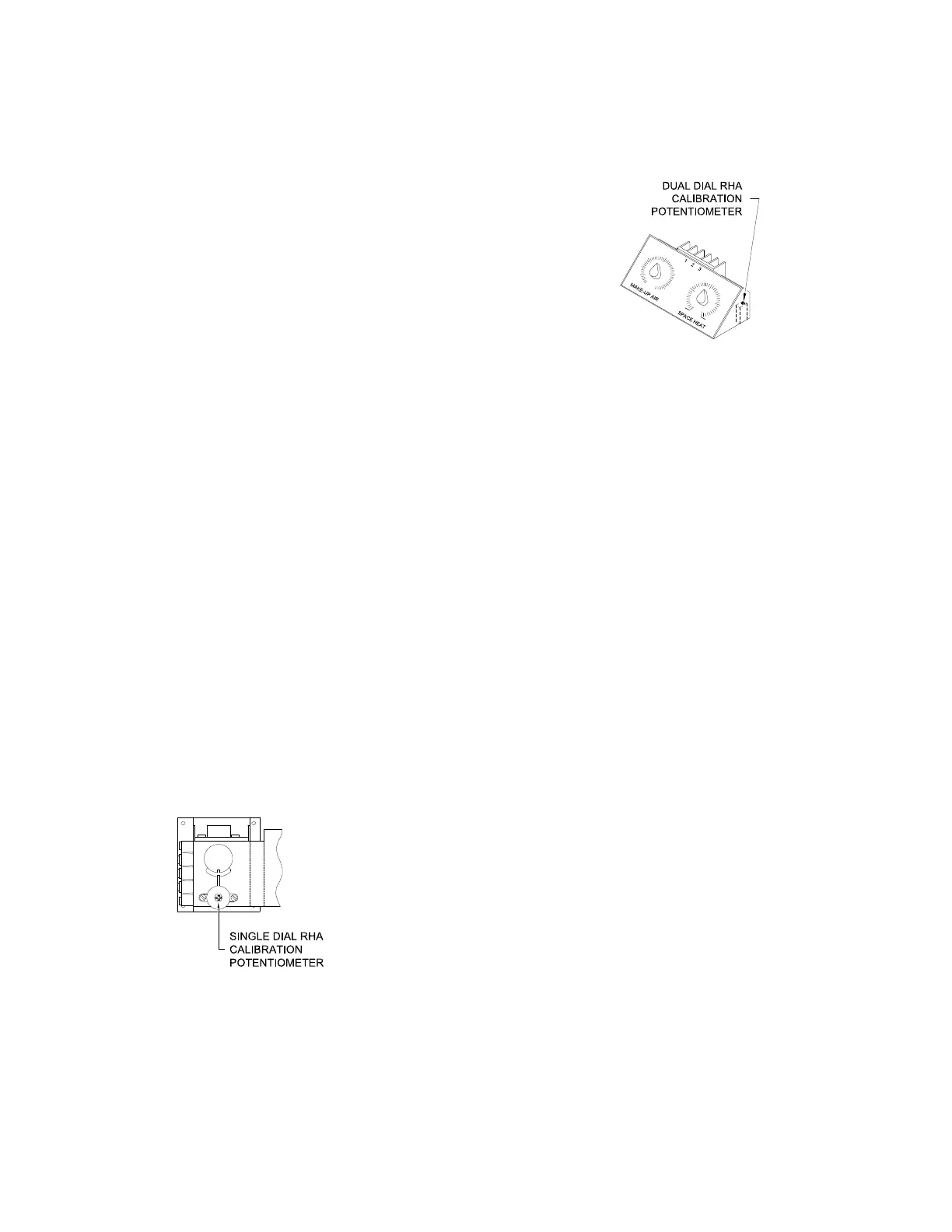

For the dual dial RHA, adjust the calibration poten-

tiometer shown in the drawing. To raise the discharge

temperature, adjust the potentiometer clockwise. To

lower the discharge temperature, adjust the potentiom-

eter counterclockwise.

10. Allow the discharge temperature and manifold

pressure to stabilize between adjustments until

the manifold pressure and discharge temperature

comply with the guidelines of the Calibration

Check procedure step "8b" (page 27).

11. Turn the burner and blower service switches to

the “OFF” position. Remove the wires from ter-

minals 1 and 3 of the RHA that were connected

in step 4. Reconnect the wires to terminal 21

and 22 of Terminal Block #1 in the unit control

enclosure. Leave the jumper in place that was

applied in step 5.

12. Return the RHA to the Remote Control Station.

Reconnect the wires that were removed in

step 2.

13. With the RHA reconnected in the Remote

Control Station, repeat steps 7 through 10. A

second technician and two-way communication

may be required.

14. Turn the burner and blower service switches to

the “OFF” position. Remove the jumper from

terminals 2 and 3 of the RHA if one was added

during step 5.

Loading...

Loading...