8

TC-003001-10/ Rev 2

Note: some installations may present unique circumstances that may require installation in a position different

than outlined above.

INITIAL INSTALLATION

The following procedure applies to new installation between standard

ASME B16.5 and B16.47 series A pipe flanges.

When replacing a valve from an existing installation, clean the flange

faces of any residual gasket material before starting.

Actuation should not be removed from the valve for installations unless

the actuator must be transferred during replacement.

1. Remove protective covers from valve. Be sure valve is completely

closed.

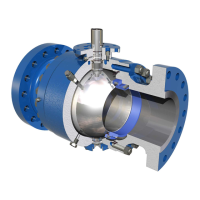

2. When installing wafer body valves, install lower flange bolts

without tightening (Figure 9). Position valve and flange gaskets

between flanges, within the pocket formed by the flange bolts.

Install the remaining flange bolts, taking care that the gaskets are

centered on the flange faces (Figure10). Note: While the WKM

DynaCentric MB High Performance Butterfly Valve has bi-

directional sealing capabilities, the preferred position is seat

upstream (Figure 6). Handle operated valves or fail close valves

should be installed seat downstream (stem side facing flow).

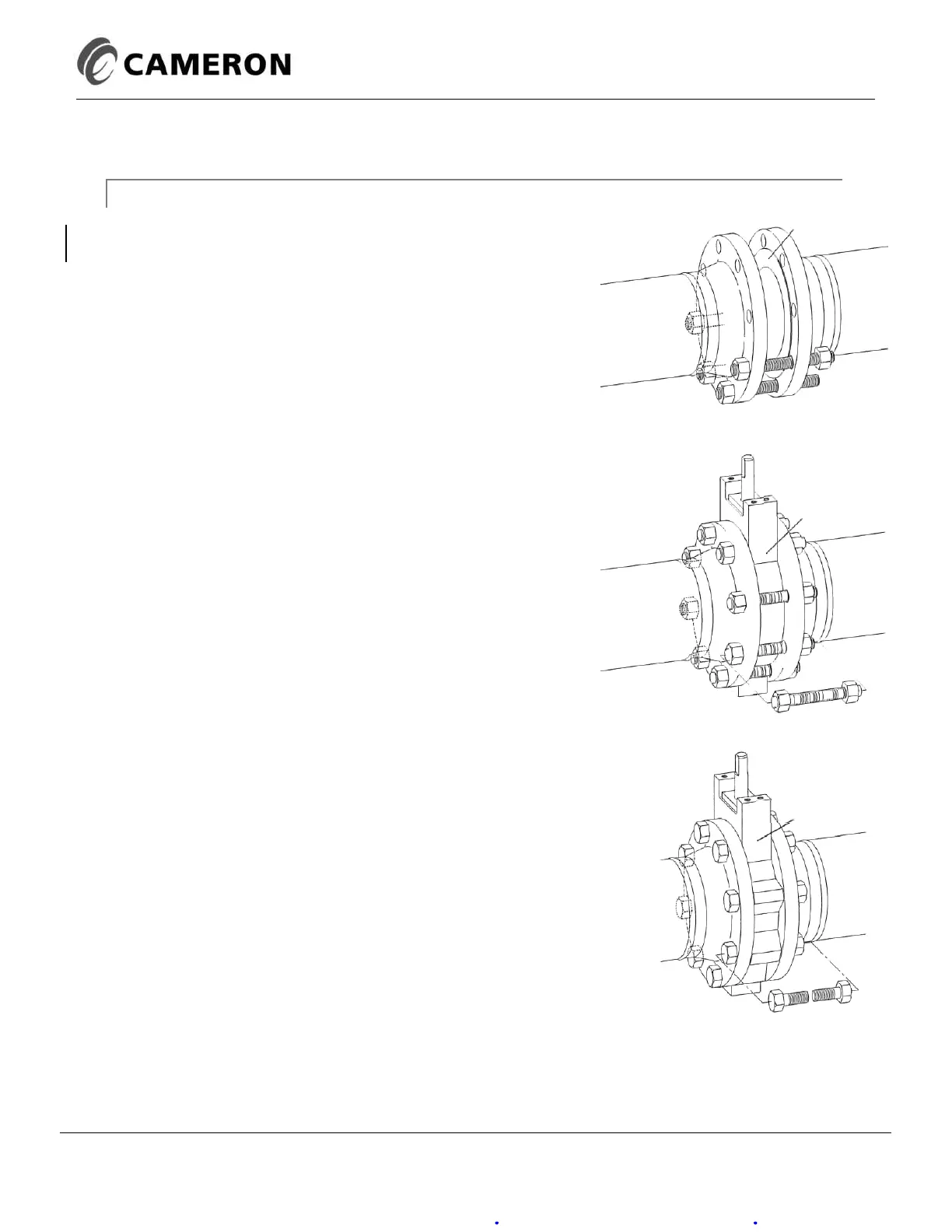

3. Lug body valves should be positioned between the flanges with

gaskets properly centered and then the capscrews inserted

(Figure 11).

4. Carefully check disc clearance by placing the valve in the full

open position. Should automated valves be difficult or impossible

to cycle, check that the raised face of the flange matches the

raised area on the valve face.

5. Tighten all bolts or capscrews in a crossover or star pattern to

insure even sealing (Figures 10 and 11).

6. Packing gland tightness is set at the factory. Should stem leakage

occur at start-up, the gland nuts can be adjusted to stop the leak.

Avoid over tightening, which could result in excessive

operating torque or premature packing wear.

Loading...

Loading...