How to fix leakage around the stem of my Cameron TK valve?

- FFrank MartinezAug 6, 2025

If there is leakage around the stem of your Cameron Control Unit valve, disassemble and replace the O-rings.

How to fix leakage around the stem of my Cameron TK valve?

If there is leakage around the stem of your Cameron Control Unit valve, disassemble and replace the O-rings.

Why is my Cameron TK valve hard to operate?

A hard-to-operate Cameron Control Unit valve can stem from several causes: the ball might not be properly aligned with the bores of seats; there could be erratic operation; ice may have formed in the valve operator; a build-up in the seat area may be present due to line contaminants; there might be restrictions in the bore of the valve, or the stop isn't set correctly; the actuator unit might be damaged; there could be a restriction of the pneumatic actuator vent, or a faulty power supply.

What to do if my Cameron Control Unit grease fitting is leaking?

If your Cameron Control Unit grease fitting is leaking, try these solutions: * Tighten the safety cap. * If the safety cap is damaged, replace it. * Inject a small amount of cleaner into the fitting to dislodge any trash.

What to do if Cameron TK valve will not seal?

If the Cameron Control Unit valve won't seal, try injecting valve sealant into the stem fitting (if present) or replace the stem O-ring. Alternatively, ice may have formed in the body of the valve; in this case, apply heat or inject antifreeze solution. Also, drain periodically to eliminate water accumulation.

What to do if Cameron Control Unit valve will not fully close?

Reset the actuator limit switches or stops for proper closing.

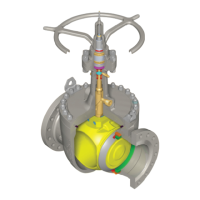

Illustration of components for a two-piece non-trunnion mounted ball valve.

Detailed itemized list of components for TK Valves, including notes and sizes.

Illustration of components for a two-piece trunnion mounted ball valve.

Detailed itemized list of components for TK Valves, including notes and sizes.

Illustration of components for a three-piece trunnion mounted ball valve.

Detailed itemized list of components for TK Valves, including notes and sizes.

Quarterly maintenance and cycling procedures for valves stored outdoors.

Storage duration limits and testing requirements for valves in enclosed facilities.

Explanation of how line pressure creates an effective seal using piston-action.

Description of self-relieving seats and their function in relieving body cavity pressure.

Step-by-step guide for attaching operators and setting closed/open stops.

Procedure for lubricating the stem seals using a vented grease fitting.

Method for checking tight closure or seat seal using the valve's bleed valve.

Steps for safely disassembling various types of TK Valves, including inspection areas.

Specific disassembly steps for two-piece seat supported valve configurations.

Specific disassembly steps for two-piece trunnion supported valve configurations.

Specific disassembly steps for three-piece trunnion supported valve configurations.

General disassembly steps applicable to all valve designs, focusing on stem and bonnet.

Key areas to inspect for damage during valve disassembly, including ball and seat surfaces.

Reassembly steps for two-piece seat supported (non-trunnion) valve configurations.

Reassembly steps for two-piece trunnion supported valve configurations.

Reassembly steps for three-piece trunnion supported valve configurations.

General assembly steps applicable to all valve designs, including final checks.

| Brand | Cameron |

|---|---|

| Model | TK |

| Category | Control Unit |

| Language | English |