ENGINEERED & PROCESS VALVES

18

01/2011 / IOM-TK-TMBV-01

Installation, Operation and Maintenance Manual

DISASSEMBLY AND REASSEMBLY

Disassembly

1.

Remove the operator from the valve bonnet. In case of lever-operated valves, remove the retaining

ring and stop plate from the stem.

2. Scribe alignment marks on the body, adapter(s) and the bonnet to ensure proper reassembly. It

is vital that the bolt holes on the pipeline flanges straddle the vertical and horizontal center-lines

of the valve.

3. Loosen all bolting.

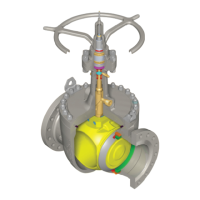

Two-Piece Seat Supported

4. Place Valve in the closed position.

5. Remove closure from the body of the valve. It may be necessary to pry apart the closure from

the body.

6. Remove ball from body cavity. (It is only possible to remove the ball before the stem on

non-trunnion mounted valves).

7. Remove bonnet and stem.

8. Remove one seat from the closure and the other from the body. Gently tapping from

underneath the seat will allow the seats to become free.

9. Collect and retain seat springs.

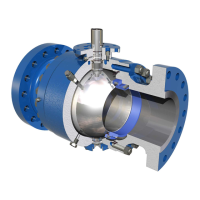

Two-Piece Trunnion Supported

4. Remove bonnet and stem from valve.

5. Remove trunnion flange. It is not necessary to separate the trunnion from the flange.

6. Remove adapter.

7. Remove ball from body cavity.

!

CAUTION

Before removing the valve from the line, make sure that the line has been fully depressurized.

For valve designs which incorporate a body bleed valve, check prior to removal from line, place

the ball in the half-open position and open the body bleed valve to relieve any retained

cavity pressure.

Once the valve is removed, appropriate isolation of the pipe ends should be undertaken by the

operator/contractor to prevent the creation of a combustible mixture where possible, and to

prevent the introduction of dirt and debris into the system.

All parts must be clean and free of dirt and foreign material before assembly. A light grease

compatible with line material and service temperature aids greatly in the assembly of

close-tolerance components. O-rings should be well-lubricated to avoid pinching between

‘mating’ parts.

Loading...

Loading...