ENGINEERED & PROCESS VALVES

01/2011 / IOM-TK-TMBV-01

13

Installation, Operation and Maintenance Manual

HYDROSTATIC TESTING

All TK Valves are tested per API-6D or API-6A test requirements. Each valve is tested to a factory closure

test at 100% of maximum operating pressure. Valves should not be used as closures for systems where

the operating pressure exceeds these figures. The valve should be left open and blind flanges should be

used as the closures. Contact our facility for full details.

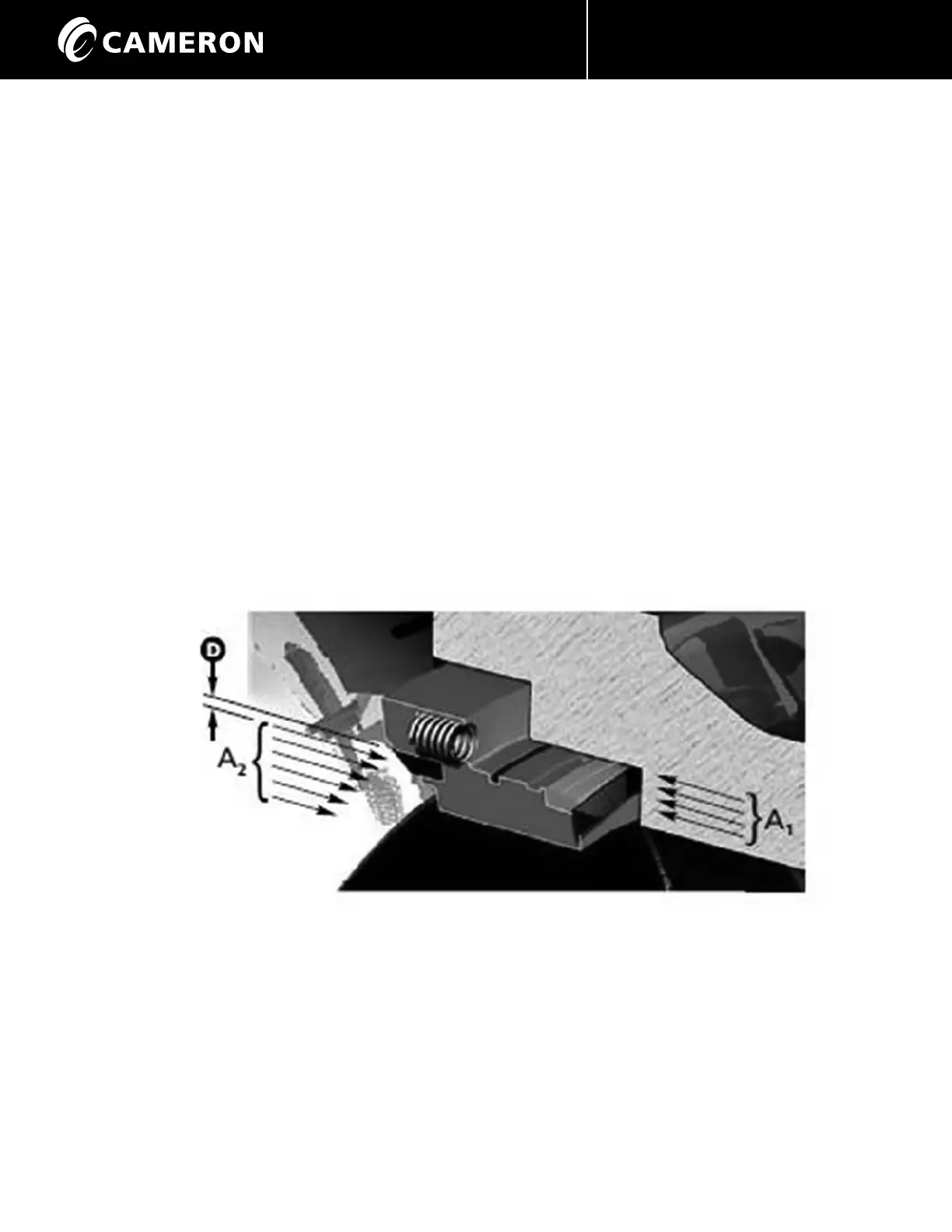

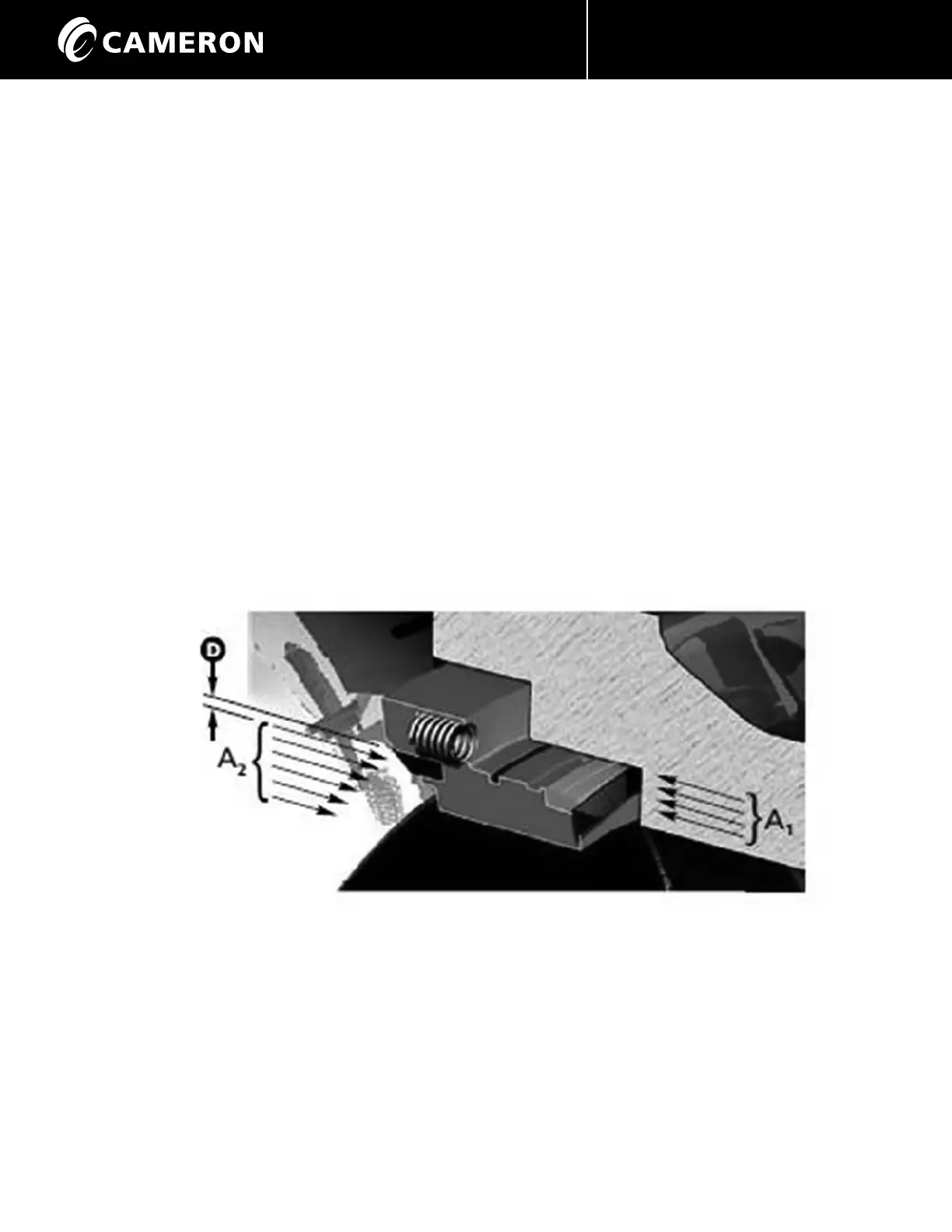

Piston-Action Seats

As line pressure increases, the seat reacts to the force of the pressure to form an effective seal. Line

pressure against the seat area A1 (see below illustration) is not equalized by pressure against seat area

A2. The difference in areas ‘piston-action’ which forces the seat unit against the ball surface. The net

result of this ‘piston-action’ is the formation of a tight, effective seal. In the absence of line pressure, coil

springs around the seat unit provide a tight seat by keeping the seat in contact with the ball surface.

Self-Relieving Seats

TK valve seats are self-relieving unless otherwise specified. This means the pressure on the ball side of the

seat will cause it to back away from the ball, thus relieving any excess pressure in the body cavity. For this

reason, it is unnescessary to install any devices to relieve excess body cavity pressure.

Loading...

Loading...