ENGINEERED & PROCESS VALVES

01/2011 / IOM-TK-TMBV-01

11

Installation, Operation and Maintenance Manual

STORAGE

These recommendations are to protect the valve/s from damage caused by direct exposure to severe

environments, indirect exposure to the surrounding environments, and general degradation due to long

term storage. Preparation for long term storage for both outside and inside enclosed areas will be

as follows.

If compatible with elastomeric materials, valves should be tested with 5 wt. oil to ensure the complete

lubrication of all internal machined surfaces. Additionally, lubrication of the valve end connection and any

other unpainted surface should be coated with rust preventive to prevent corrosion. Flange covers and/or

end caps must be in place in order to prevent any ingress of foreign materials. Lost, cracked, or otherwise

damaged covers should be replaced immediately.

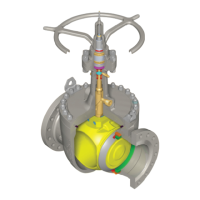

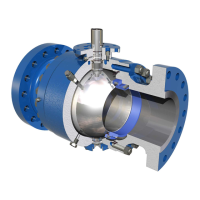

Valves 4” and smaller have only one giant buttonhead fitting located in the valve body with an additional

zerk type fitting located on the bonnet. Valves 6” and larger feature four giant buttonhead fittings

located on the end pieces of the valve (also referred to as “adapters”) plus a zerk type fitting on the

bonnet. The quantity and type of fittings on gearboxes vary with make and model. Each fitting should be

injected with appropriate type and amounts of grease prior to storage. Lubrication fitting covers should be

replaced and remain in place during storage.

Valves should be skidded and covered with a plastic film bag to prevent dust accumulation and any ingress

of sand, dirt, or moisture from entering into the valve. A Vapor Corrosion Inhibitor (VCI) should be inserted

into the envelope of the valve to assist in removing moisture from the valve.

Records of valve maintenance should be kept.

Long-term Outside Storage

If valves are stored outdoors we recommend the following.

On a quarterly basis each stored valve should receive a 1-ounce shot of approved lubricant in each of the

valves fittings, including the gearbox and stem fittings. Fitting covers should be inspected and replaced if

necessary at this time.

On the same schedule as above and immediately following lubrication, each stored valve should be cycled

once from the fully open position to the fully closed position, and then returned to the fully open position.

Leaving the valve in some intermediate position for any period of time may result in permanent damage to

the soft valve seat. End covers should not be removed to inspect the valve bore at this time unless there is

reason to suspect other damage to the valve.

Long-term Enclosed Storage

Valves must be stored in a totally enclosed storage facility.

Valves left in storage for periods greater that three (3) years should be hydrostatically tested prior to

installation. Valves left in storage for periods greater than six (6) years should be disassembled, cleaned and

inspected for damage. All elastomeric seals should be replaced at that time.

Loading...

Loading...