ENGINEERED & PROCESS VALVES

16

01/2011 / IOM-TK-TMBV-01

Installation, Operation and Maintenance Manual

ROUTINE MAINTENANCE

Lubrication of TK Valves is not necessary for all applications, and is not a requirement for the valve to

seal pressure. In certain applications however, as in dry gas for example, lubrication twice yearly is

recommended. This lubrication reduces the stem torque, making the valve easier to operate, and reduces

wear of the stem, seat and ball. Biannual greasing of the stem gland also reduces torque and extends

stem, bonnet, and stem O-ring life.

Medium weight grease is recommended and has been field tested and proven to be very effective in

reducing torque.

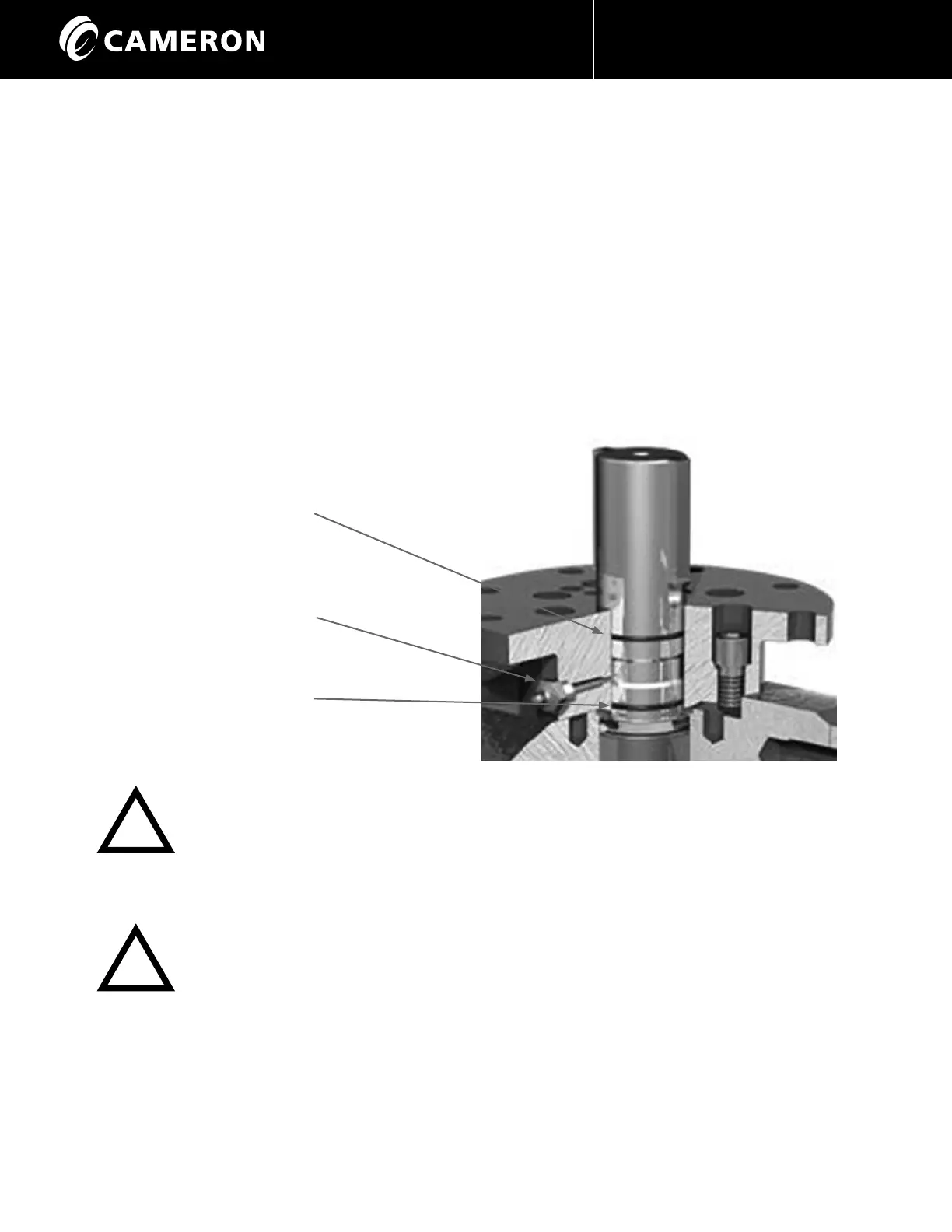

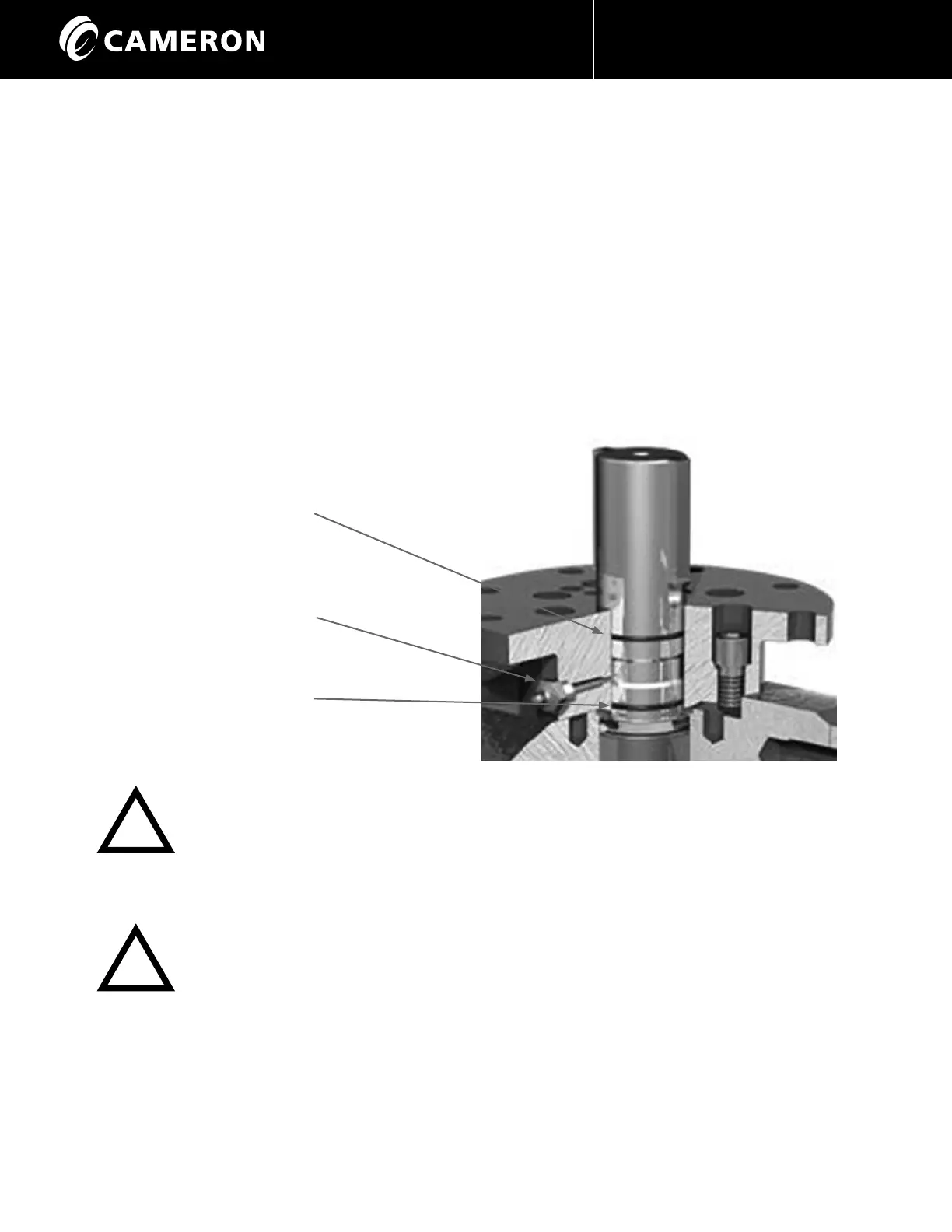

Stem Lubrication

Access for lubricating the stem seals is through a vented grease fitting that is located on the stem

bonnet. There are two O-rings on the stem. The bottom O-ring is the primary pressure seal and the top

O-ring is a weather seal. All TK Valve sizes and models will incorporate this bonnet/stem grease fitting.

Weather Seal

Vented Grease Fitting

Primary Pressure Seal

Caution:

In the unlikely event of a primary stem seal failure, leaks will occur through the grease

fitting. To temporarily fix the leak, the vented grease fitting can be replaced with a 1/8”

NPT

pipe plug. This will cause the weather seal to become the primary pressure seal. At this

time both of the stem seals should be replaced at the earliest opportunity. DO NOT remove

the bonnet while the valve is under pressure!

Warning:

Under no circumstances must the slotted vented grease fitting be replaced with a non-slot-

ted grease fitting.

Checking for Seat Leakage

All trunnion mounted TK Valves are incorporated with a Bleed Valve. To check for a tight

closure or seat seal, open the needle (bleed) valve slightly. After initial blow-down, there

should be no additional flow.

TK Valves in buried services are equipped with watertight extensions. Sealant and bleed

fittings are carried to the top of the extension when required.

!

!

CAUTION

WARNING

Loading...

Loading...