ENGINEERED & PROCESS VALVES

01/2011 / IOM-TK-TMBV-01

15

Installation, Operation and Maintenance Manual

Once the alignment is accomplished, loosen the jam nut on the open stop bolt and turn the stop bolt

clockwise until it stops. Retighten the jam nut.

It may be necessary to turn the stop screw counter clockwise in order to get additional travel. Move the

operator farther open, in order to align the ball flow bore with the flow bore of the seatholder. The

handwheel should always be turning in the open direction to set the open stop, so that all slack will be

taken out of the gearing. This ensures a more accurate stop setting.

After setting the open stop a quick check should be made to ensure that it has been set correctly. This is

accomplished by turning the handwheel shaft several turns towards closed then returning it until it hits

the open stop. There should be no more than 1/16” of the ball radius exposed into the flow bore after

the stop is properly set. If further alignment is necessary screw the open stop screw in or out to readjust

the ball travel.

Replace indicator cap and tighten all fasteners.

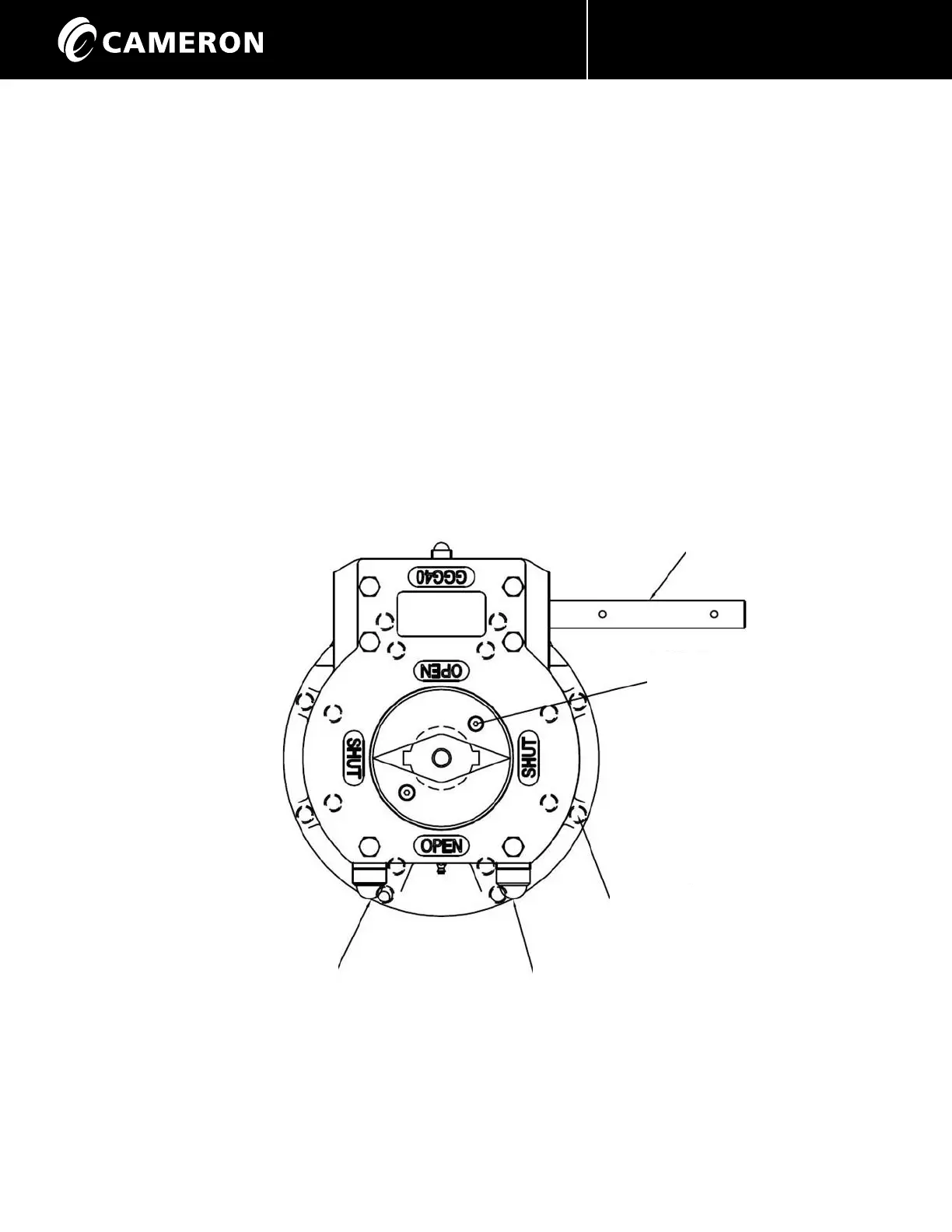

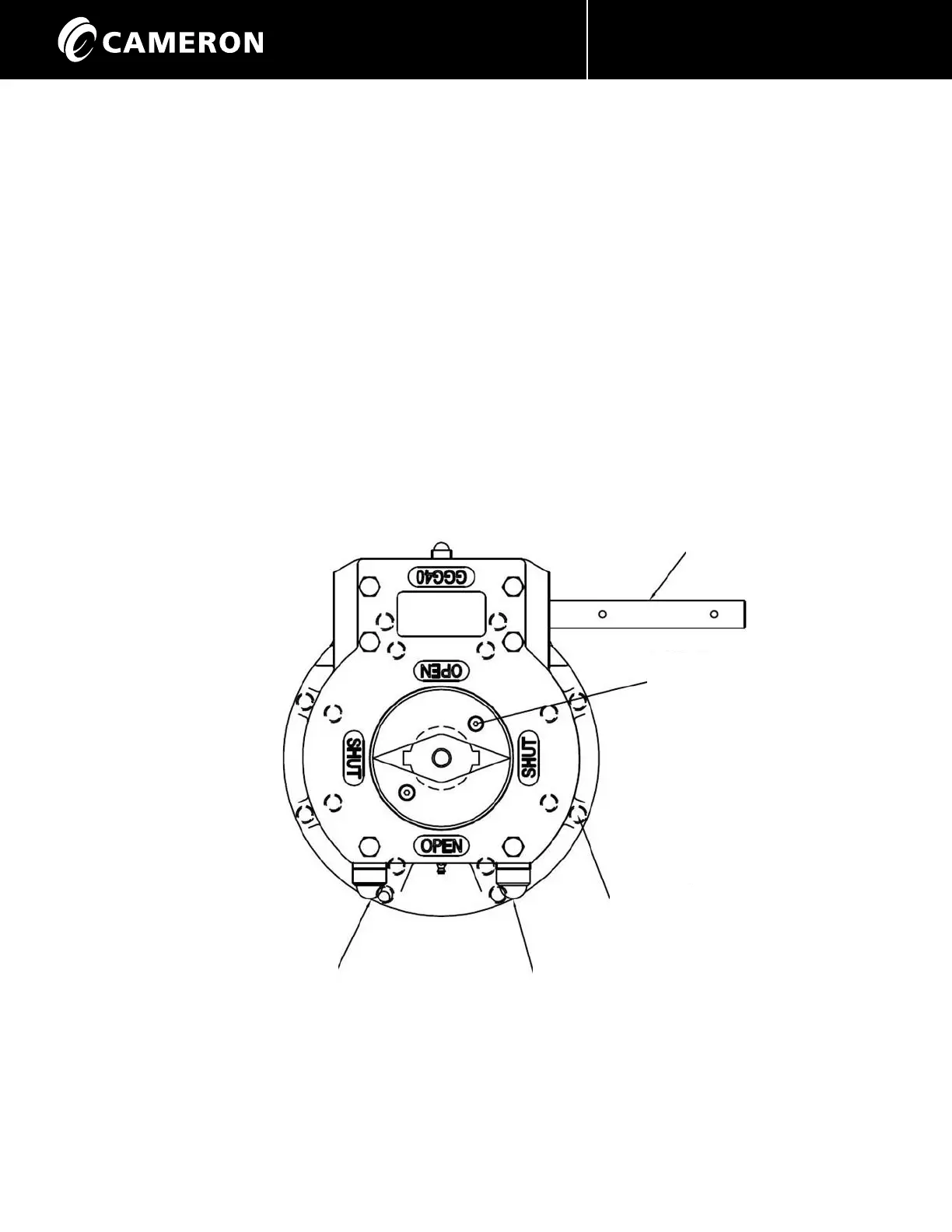

Handwheel Shaft

Indicator Cap

(Shown in Closed Position)

Stud Holes

Open Stop Screw

Closed Stop Screw

Loading...

Loading...