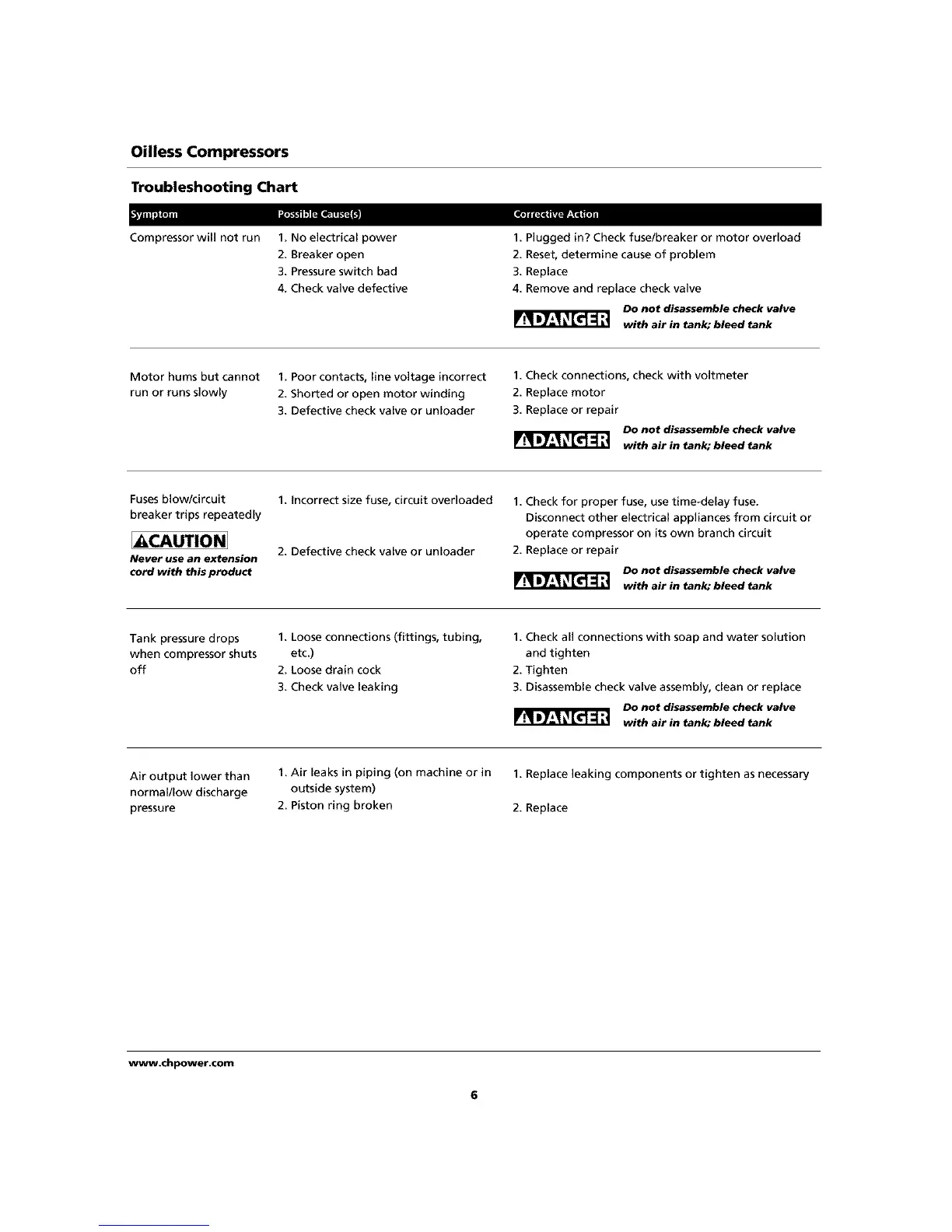

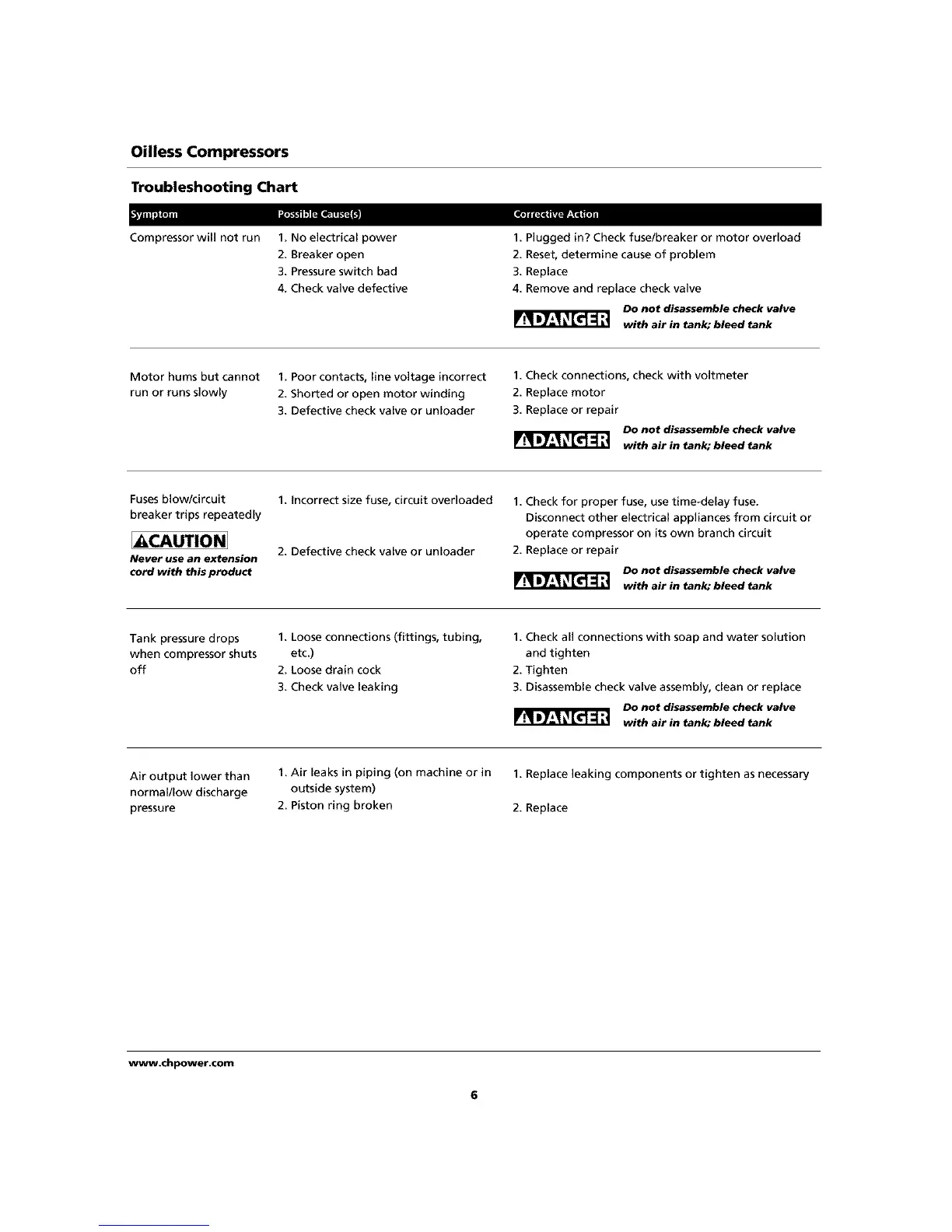

Oilless Compressors

Troubleshooting Chart

Compressor will not run 1. NO electrical power

2. Breaker open

3. Pressure switch bad

4. Check valve defective

1. Plugged in? Check fuse/breaker or motor overload

2. Reset, determine cause of problem

3. Replace

4. Remove and replace check valve

DO not disassemble check valve

with air in tank; bleed tank

Motor hums but cannot

run or runs slowly

1. Poor contacts, line voltage incorrect

2. Shorted or open motor winding

3. Defective check valve or unloader

1. Check connections, check with voltmeter

2. Replace motor

3. Replace or repair

DO not disassemble check valve

with air in tank; bleed tank

Fuses blow/circuit

breaker trips repeatedly

[ACAUTION]

Never use an extension

cord with this product

1. Incorrect size fuse, circuit overloaded

2. Defective check valve or unloader

1. Check for proper fuse, use time-delay fuse.

Disconnect other electrical appliances from circuit or

operate compressor on its own branch circuit

2. Replace or repair

DO not disassemble check valve

with air in tank; bleed tank

Tank pressure drops 1. Loose connections (fittings, tubing,

when compressor shuts etc.)

off 2. Loose drain cock

3. Check valve leaking

1. Check all connections with soap and water solution

and tighten

2. Tighten

3. Disassemble check valve assembly, clean or replace

DO not disassemble check valve

with air in tank; bleed tank

Air output lower than 1. Air leaks in piping (on machine or in 1. Replace leaking components or tighten as necessary

normaVIow discharge outside system)

pressure 2. Piston ring broken 2. Replace

www.chpower.com

Loading...

Loading...