VARIOUS ADJUSTMENTS

POINT ADJUSTMENT.- These are l

o-

cated

on the l

eft

side

of

the

eng

ine, insi

de

the magneto flywheel,

which

is protected by

a cover. Before adjusting

the

points, their

condition

should be checked. If they are burn-

ed

or

any

of

them show a perforation, they

should be

sande

d with fine

sandpaper

or

a

file before being

calibr

ated. If the perforation

is very

deep

,

or

if the

po

ints have previously

been sanded and are very worn, they

should

be replaced

by

new

one

s.

Whe

n installing

the

new

points, be s

ur

e

to

clean them very

well. The points generally have a protective

layer of

gr

ea0e, which should be removed

once

they are

goin

g to be used. When in-

stalling them on the s

uppo

rt

disk

, be

caref

ul

that the moveable

po

int remains isolated,

that is to say that

r~either

the

point nor t

he

connections

which

reach it are

grounded

,

since this

would

c

au~e

a short circuit pre-

venting the current fr

om

reaching the

spark

plug.

Under

these conditions

we

can

now

pro-

ceed to

calibrate

the

sp

ace between points.

For this

operat

i

on

we turn

the

propeller

shaft

to a

pos

ition

suc

h that t

he

u

pp

er

part

of

t

he

ma

gneto fl

ywhee

l

cam

operates

aga

inst

the

shank of

the

moveable

point. In this position,

loosen the

screw

which holds the fixed

po

int

and move it in the

direct

ion necessary

to

ob

tain the

cor

r

ec

t calibration,

which

sh

ould

be between 0.3 and 0

.4

mm. Then tighten

the

screw

which

holds the fixed

point

a

nd

check

the calibration again.

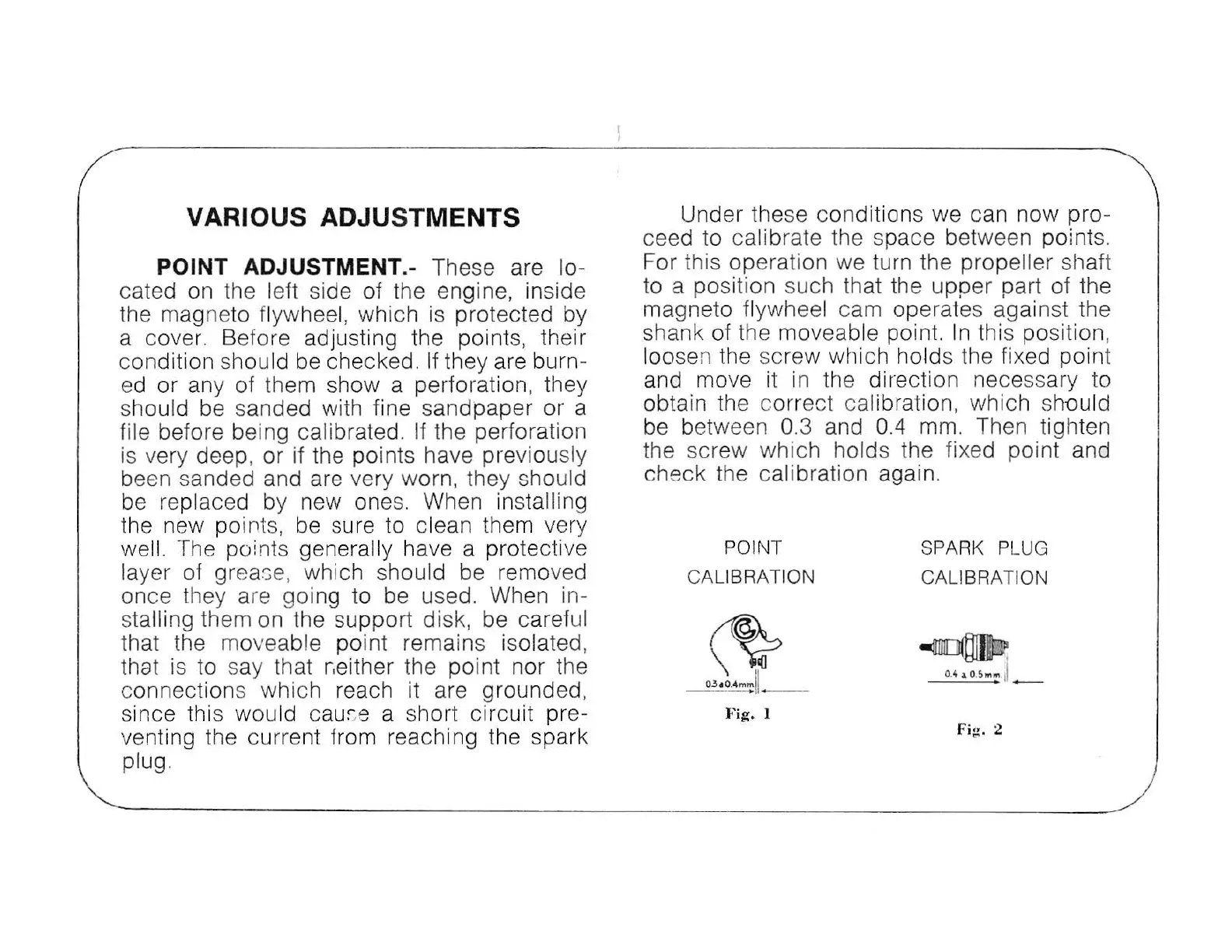

POINT

CALIBRATION

~

03

•0

.

4"'

"'

11

--

F

i

~.

1

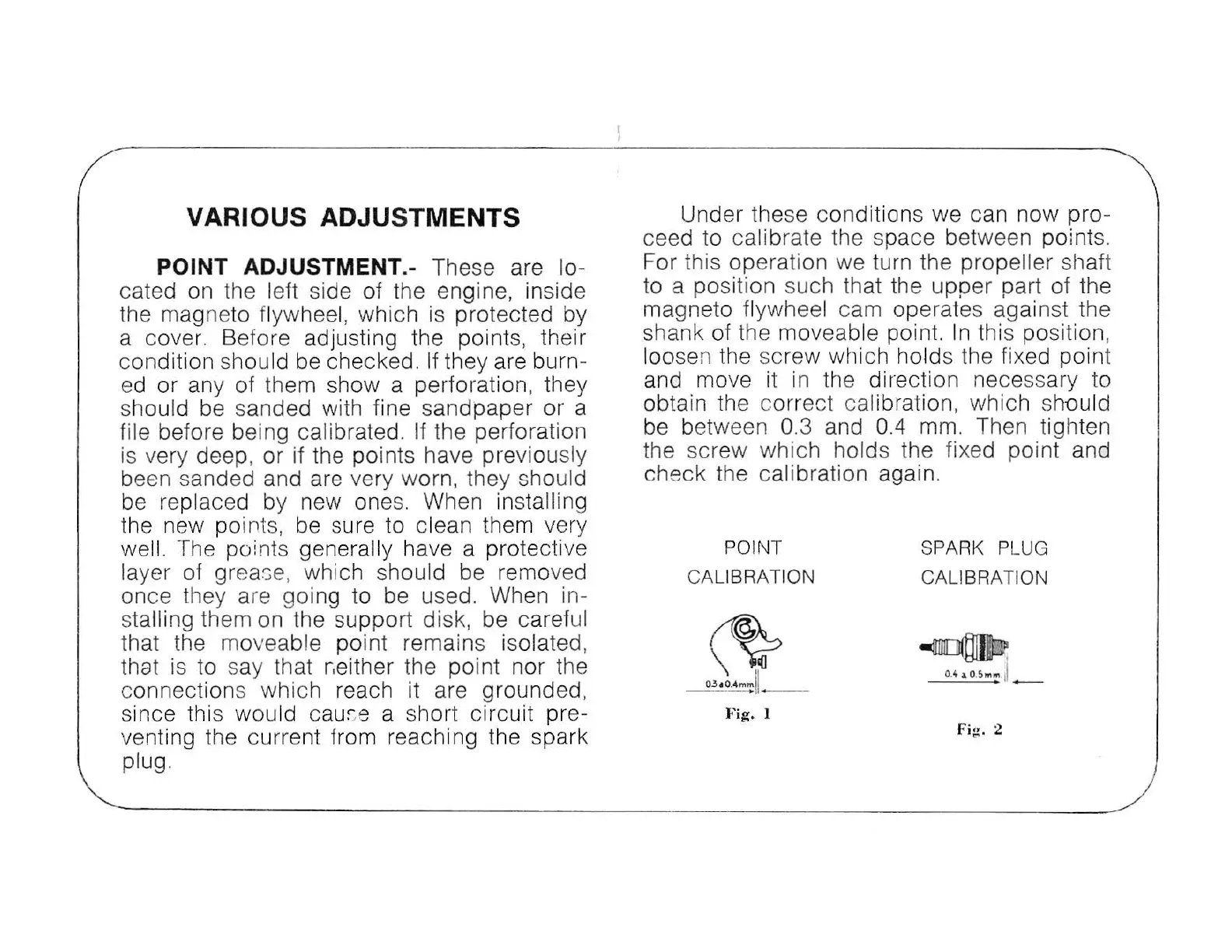

SPARK

PLUG

CALIBRATION

Fig. 2

Loading...

Loading...