8

ENG

c.pCO sistema +0300057EN rel. 1.2 - 29.05.2017

Applications

When provided with a dedicated application program, the controller can be used

to control dierent kinds of equipment:

• chillers and heat pumps;

• roof-top units;

• air-conditioners;

• small/medium-sized air handling units (on request);

• refrigerated showcases (on request and to specications);

• cold rooms (on request and to specications);

• curing rooms;

• compressor racks;

• universal stage controllers.

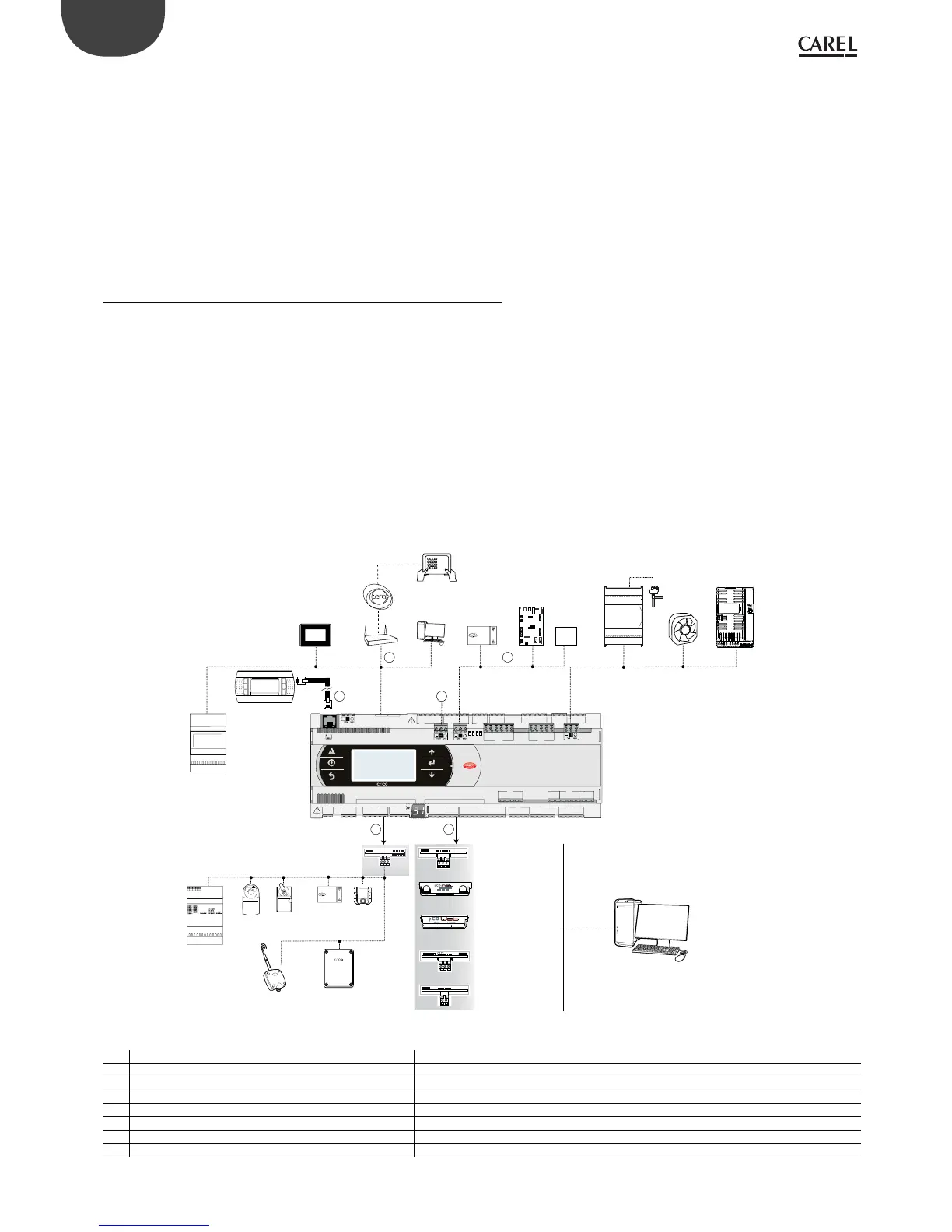

1.1 Functional layout

The gure below shows the functional layout of an air handling unit. Damper

actuators and valve actuators are eld devices that communicate through

Fieldbus 1 (ref. C). Fieldbus 2 (ref. E) is the medium through which the serial probes

communicate the values measured, and through which the humidier control

board and the fans exchange data and receive set points from the controller. The

built-in terminal and the remote terminal, which communicate via pLAN (ref. A),

are used for installing the application program and for commissioning the system.

The PGD touchscreen terminal, intuitive and simple to use, can be used while the

unit is normally working to set switch-on and switch-o times, to enter the main

parameters, to perform other advanced functions of the application program and

to view any alarms triggered. In this case data are exchanged via Ethernet port (ref.

D). In the same network it is possible to connect another c.pCO controller as well

as to communicate with remote cloud service tEra or to BACnet™ supervisor. The

system can be connected to other supervision systems (Konnex®, LON®, etc.) after

installing the relative BMS1 expansion card (ref. B).

584SRsutats

GNX RS485

+ –

P1 P2 P3

BA Cnet

™

MS/TP

FieldBus 1

BMS 1

J1

J24 J2 J3

J4

J5 J7

J8

J20

J21

J14

J10

J13J12

J22

J16 J1

7

J18

J15

J6

J19

FieldBus card

B M S card

J23 FBus2

J11 pLAN

J25 BMS2

J26 FBus2

43 2 1

touch screen

pGD1

FieldBus 2

Ethernet

pLAN

A

D

E

C

B

EVDevolution

c.pCOe

c.pCO mini

tERA cloud

service

Power +

FAN

EVD

Evolution

PC

BELIMO

BELIMO

tDisplay, tService

F

Router

RS485 serial card

FieldBus serial card

Damper

servo-control

Servo-control

valve

Serial probes

th-Tune

Access Point

Speed regulator

pGD terminal

Humidifier

control board

Serial probes

Third part

device

interface

interface

interface

interface

BACnet™ RS485

Ethernet™ /BACnet™

LonWorks ®

Konnex

®

Fig. 1.a

Ref. Serial port/Connectors Connection to:

A pLAN/J10, J11 up to 3 terminals (e.g. pGD1, pLDPRO)

B BMS 1 Serial Card a building automation system, after installing the special BMS card (see par. 1.3)

C FieldBus 1 Serial Card sensors, actuators, etc., on a Fieldbus, after installing the special card (see par. 1.4)

D Ethernet pGD Touch terminals, c.pCO controllers, Router-->tERA

E FieldBus 2 / J26 (e J23 in Large, Extralarge models) sensors, actuators, etc., on a Fieldbus (built-in card)

F BMS 2 / J25 other devices (built-in card)

Loading...

Loading...